The Technological Method of Detecting Dimensional Parameters of Railway Passenger Car Bearings

A process method and technology for detecting data, applied in measuring devices, instruments, inductive recording carriers, etc., can solve the problems of high error probability and poor traceability of manual recording, and achieve the elimination of complexity and inaccuracy, accurate information, and identification. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

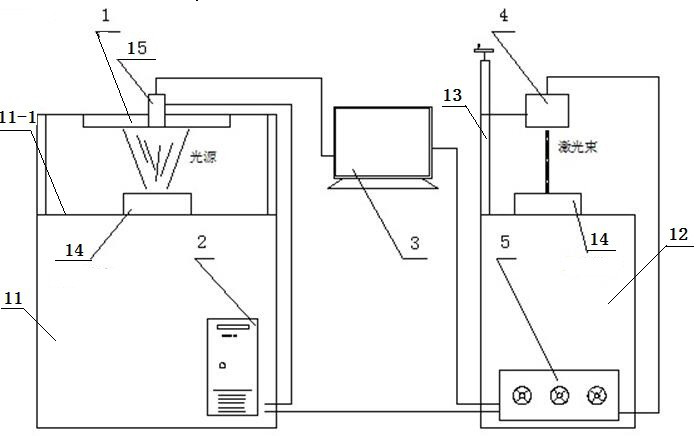

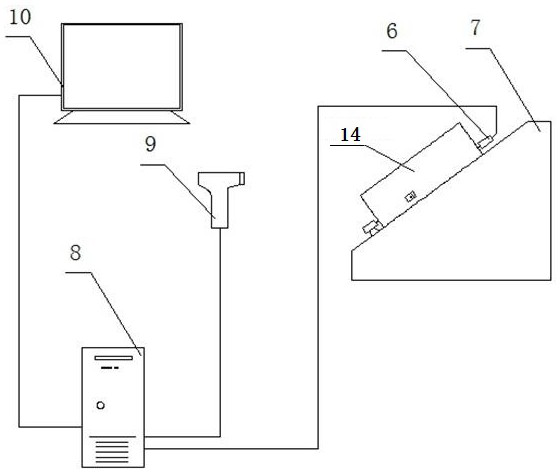

[0019] The railway passenger car bearing of the present embodiment adopts a two-dimensional code generating system to generate two-dimensional codes. The printer 4 and the laser generator 5, the CCD scanning camera and the light source device 1 of the two-dimensional code generation system are arranged on a counter 11 through the support arm 15, and the illumination of the light source device faces the countertop 11-1 of the counter. The image two-dimensional code CPU processor 2 is installed in the cabinet of the counter, the input end of the image two-dimensional code CPU processor 2 is electrically connected with the output end of the CCD scanning camera and the light source device 1, and the CCD scanning camera and the light source device 1 are connected with the first An operation screen 3 is electrically connected, and the laser engraving machine 4 is horizontally suspended on a platform 12 through a mounting frame 13. The laser engraving machine is electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com