Manufacturing method for pipe structure

A manufacturing method and structure technology, applied in the field of tube structures, can solve problems such as inability to eliminate defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention will be specifically described below with reference to the drawings.

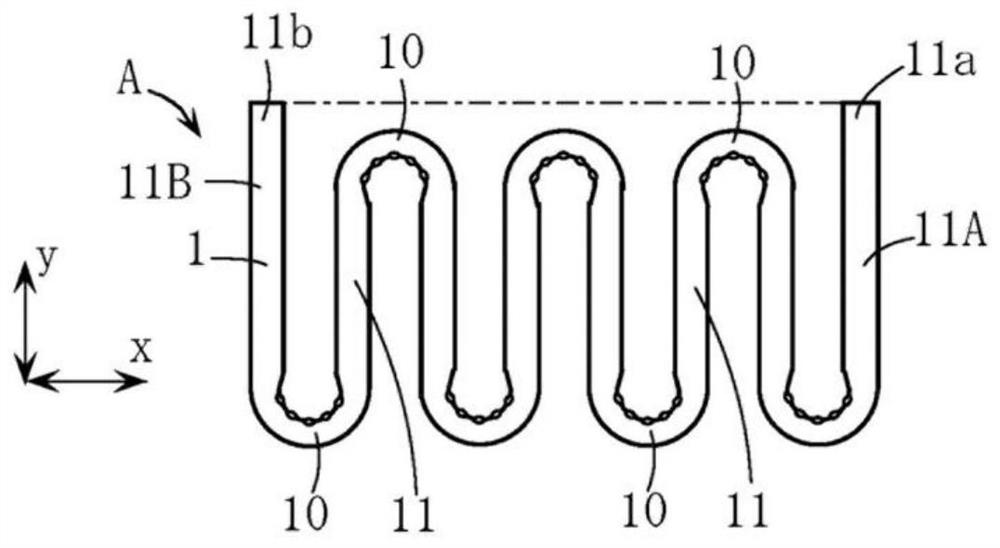

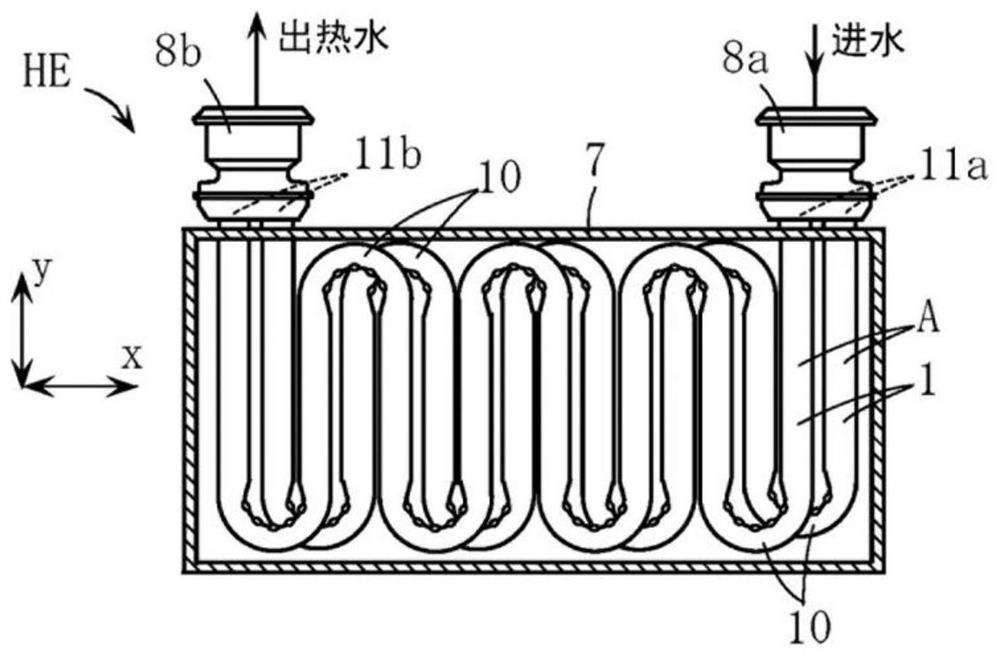

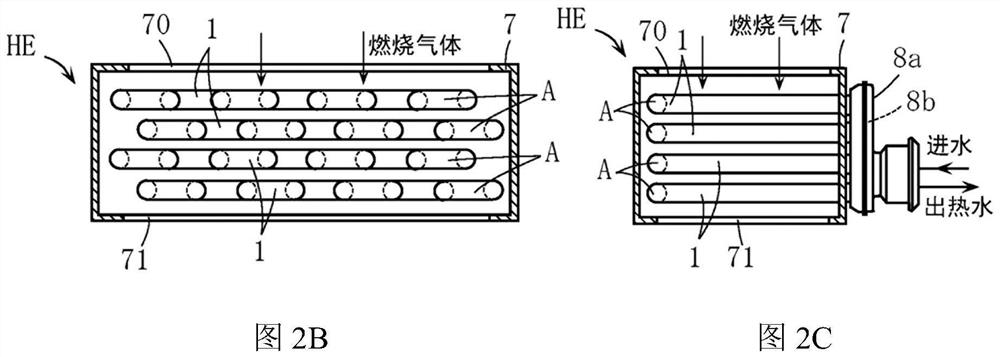

[0042] The manufacturing object of the manufacturing method of the pipe structure of this embodiment is the same as the already described prior art. figure 1 The serpentine tubular body A shown. Therefore, the same reference numerals as those of the above-mentioned prior art are attached to the same or similar elements as those of the above-mentioned prior art.

[0043] First, the serpentine tubular body A will be described.

[0044] As already described, the serpentine pipe body A is formed by, for example, a stainless steel pipe 1 formed in a serpentine shape, has a plurality of bent portions 10 with a bending angle of 180 degrees, and is formed by these plurality of bends. A plurality of linear portions 11 connected to each other. Areas 11A, 11B near both ends of the pipe 1 are figure 1 It is separated in the widthwise direction of the x-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com