Process for controlling dust in belt roadway by sections through water spray

A segmented control, fine water spray technology, used in dustproof, safety devices, mining equipment and other directions, to achieve the effect of uniform water mist, long suspension time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

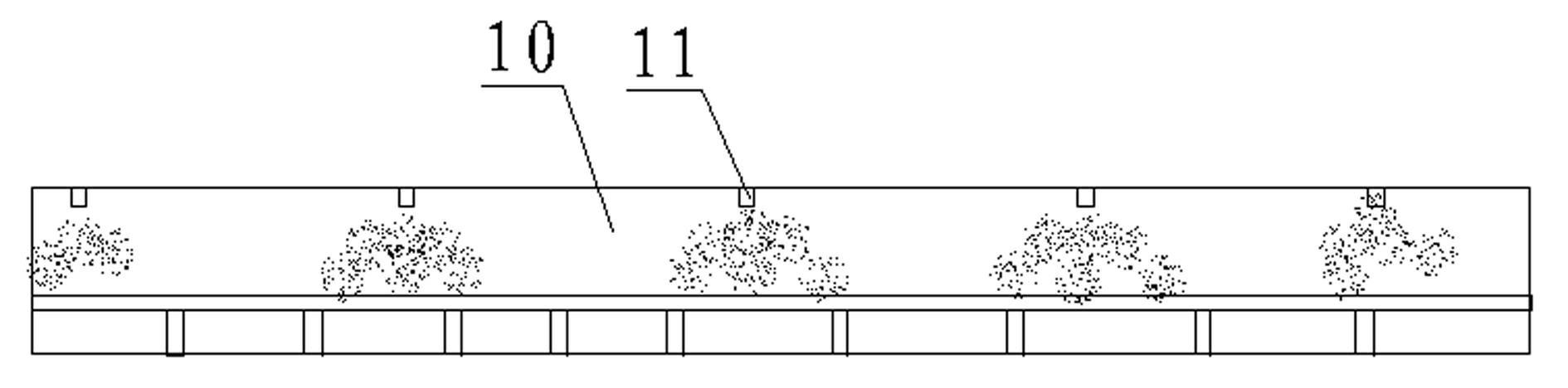

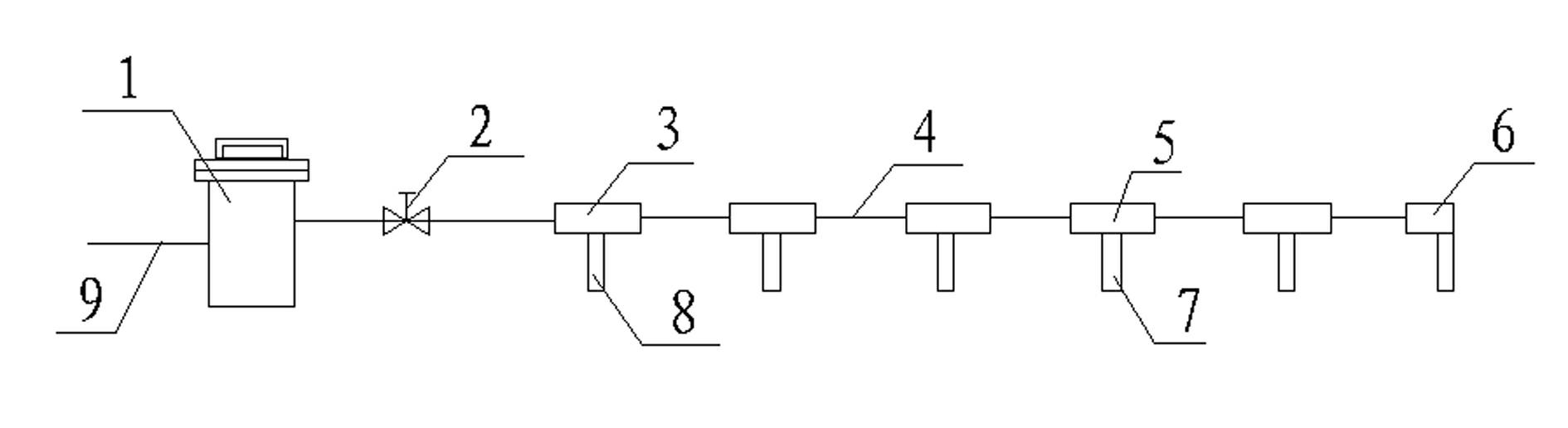

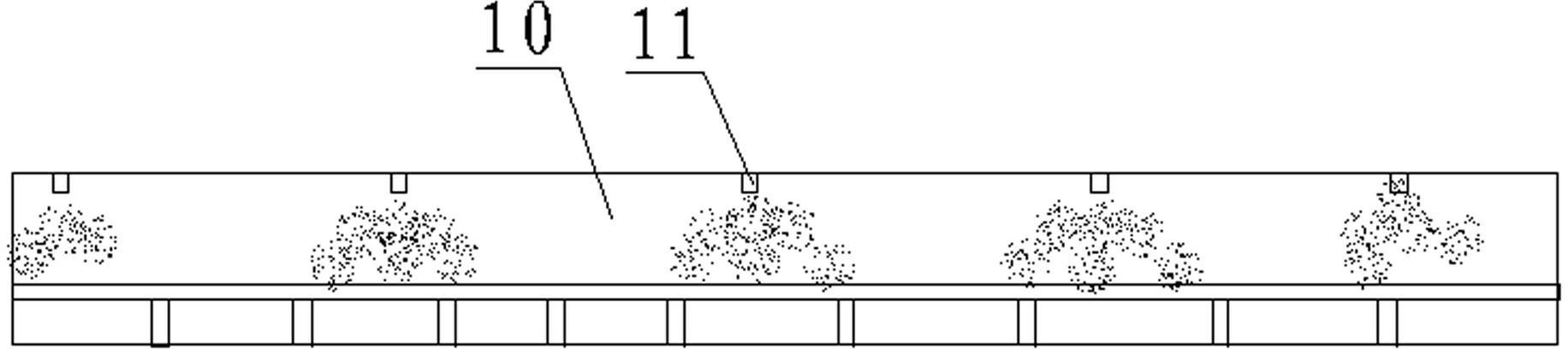

[0010] Such as figure 1 As shown, a fine water spray subsection control belt lane dust process, a spray device 11 is arranged every 40-60 meters in the lane 10, such as figure 2 As shown, the spray device 11 includes a water inlet pipe 9, a water purifier 1, and fine water atomization nozzles 8 and 7 connected in series. The distance between the fine water atomization nozzles is 0.3-0.5 meters, and the water quality filtration accuracy reaches 1000 mesh. , water pressure 1MPa~10MPa 。

[0011] The specific structure of the spray device is that the water inlet pipe 9 connected in sequence, the water quality purifier 1, the ball valve 2, the nozzle pipe 4, and the nozzle pipe 4 are connected with straight-through nozzle seats 3, 5, terminal nozzle seats 6, and fine nozzles installed on the nozzle seats. Water atomization nozzle 8,7. Open the ball valve of the water supply pipeline to let the sundries in the pipeline flow away, then close the ball valve of the water supply pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com