Detachable waste heat recovery high-efficiency heat exchanger

A waste heat recovery and heat exchanger technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of low thermal efficiency of waste heat recovery devices and the inability to replace the occupied area, so as to achieve effective utilization Effect of residual heat, flexibility of tube bundle bandage, uniform heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Such as Figure 1-10 shown.

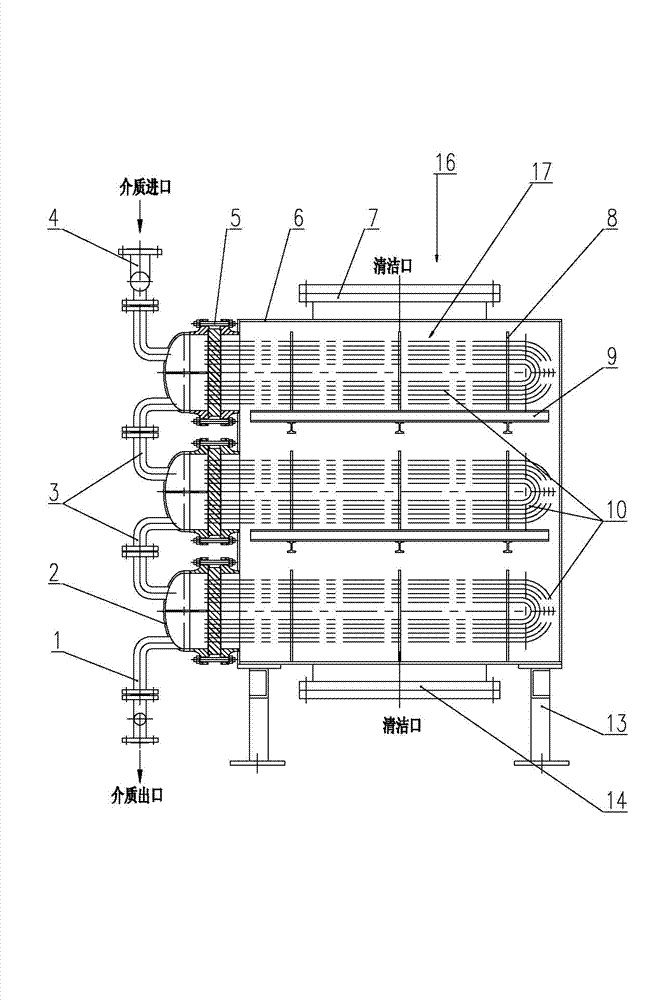

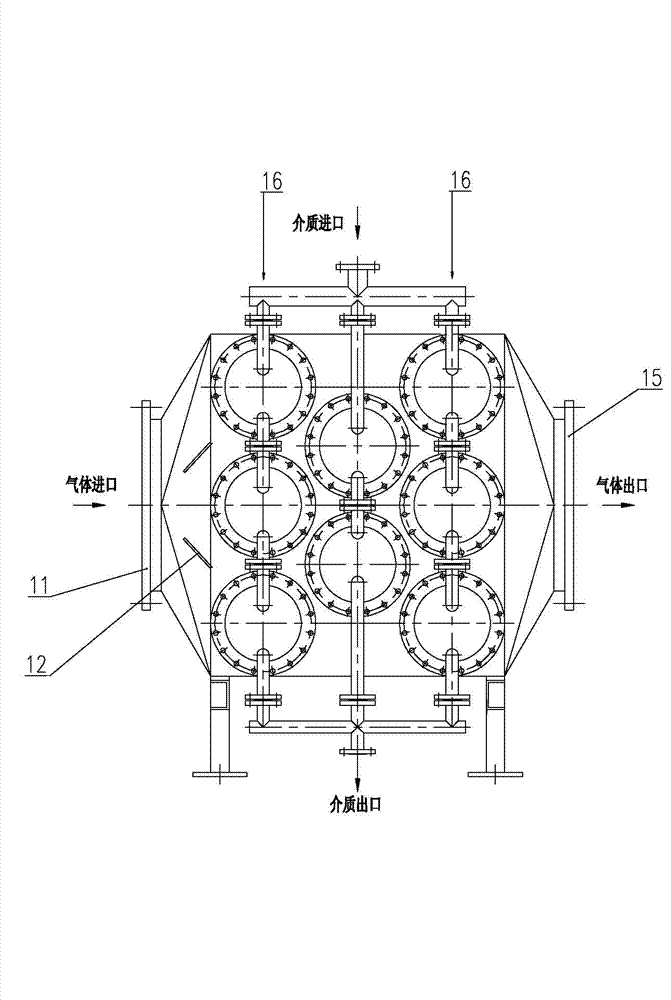

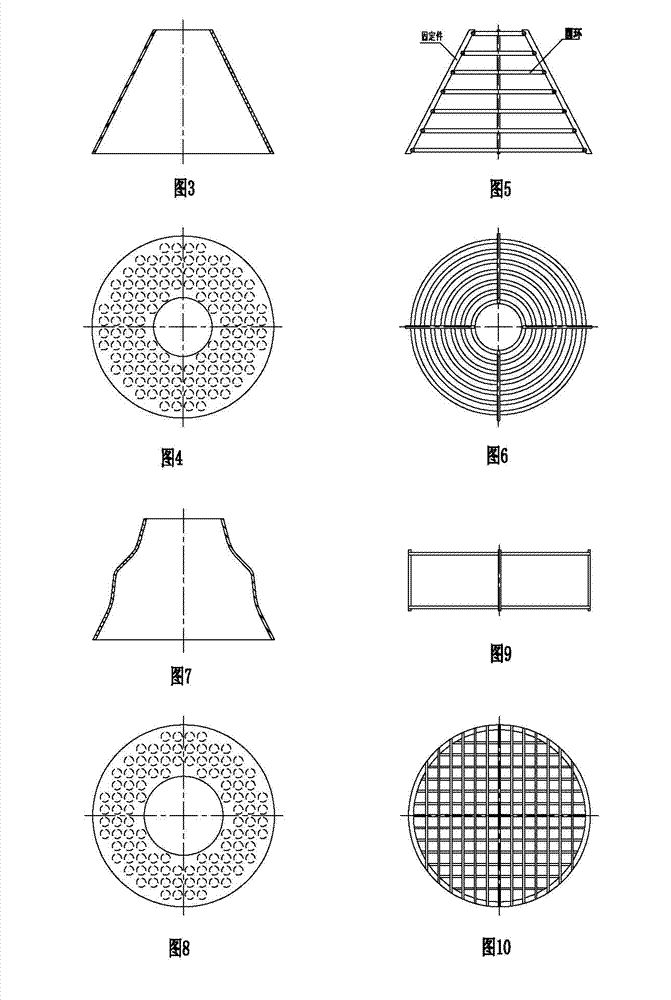

[0032] A detachable waste heat recovery high-efficiency heat exchanger, which includes a shell 6, one end of the shell 6 is provided with a conical fluid inlet 11, and its other end is provided with a conical fluid outlet 15, such as figure 1 As shown, the upper part of the housing 6 is provided with an interface (manhole) 7 for cleaning and replacement operations, and the lower part is provided with an interface (manhole) 14 for cleaning and replacement operations. The housing 6 is integrally supported and installed on the support 13, such as figure 2 As shown, a fluid distributor 12 is installed in the conical fluid inlet 11, and the specific structure can be adopted Figure 3-10 In any structure shown, the fluid distributor 12 is a plate fixed on the shell 6 or the inlet pipe wall, and can be a long plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com