Control system and control method for dynamic reactive power compensator

A control system and compensator technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation and other directions, can solve the problems of large compensation capacity, slow response speed, and dynamic reactive power compensation speed that cannot meet the requirements, etc. To achieve the effect of reducing the capacity of the device and increasing the compensation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

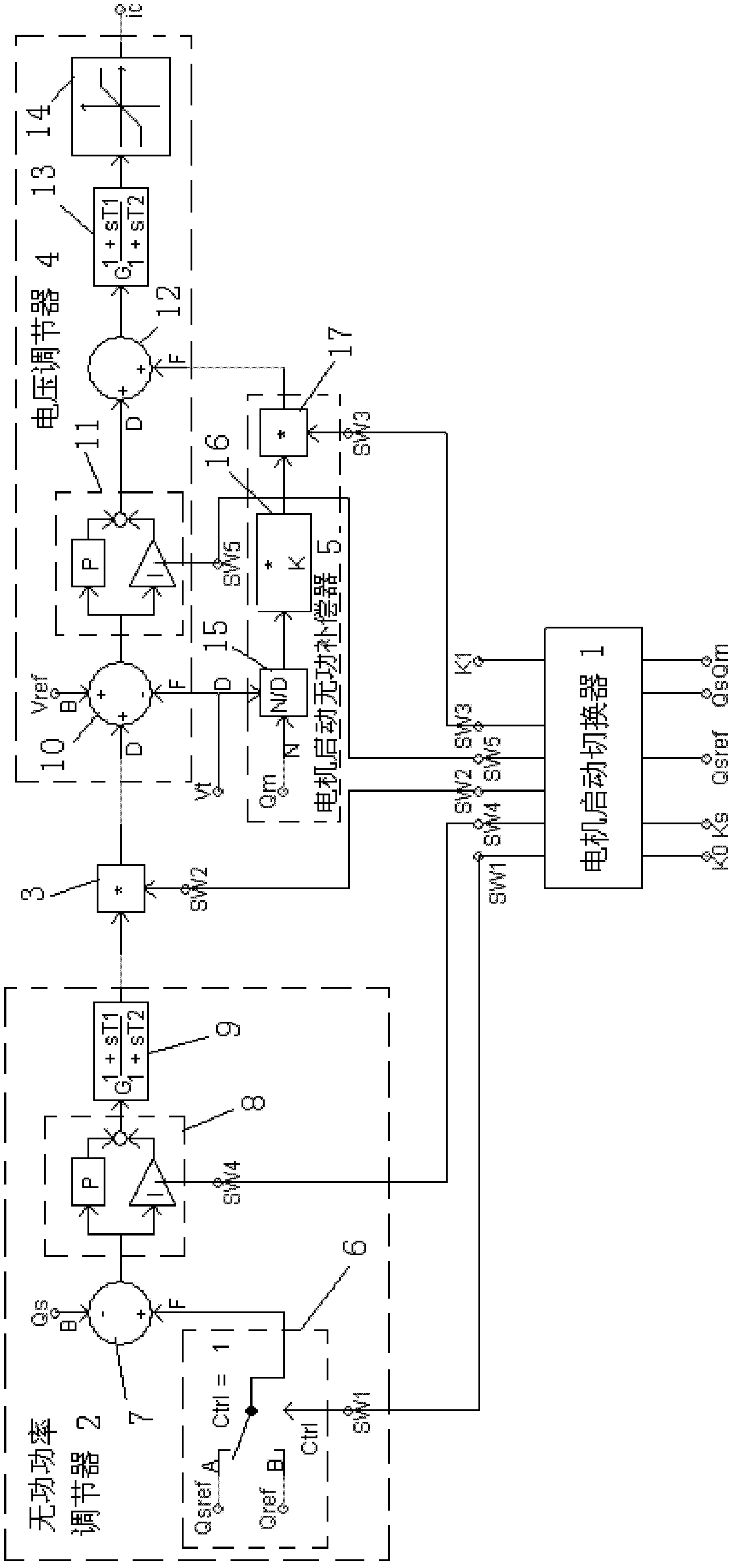

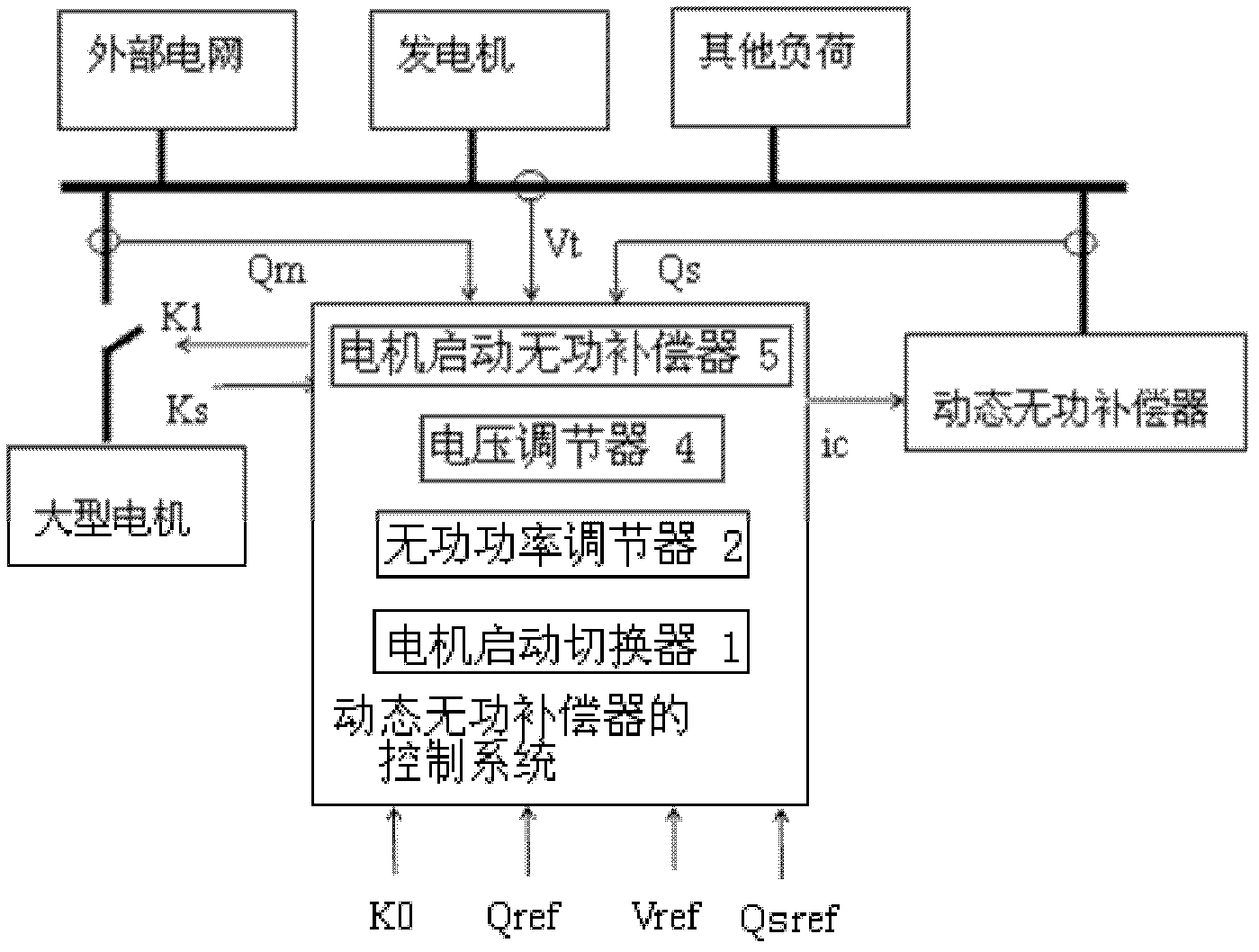

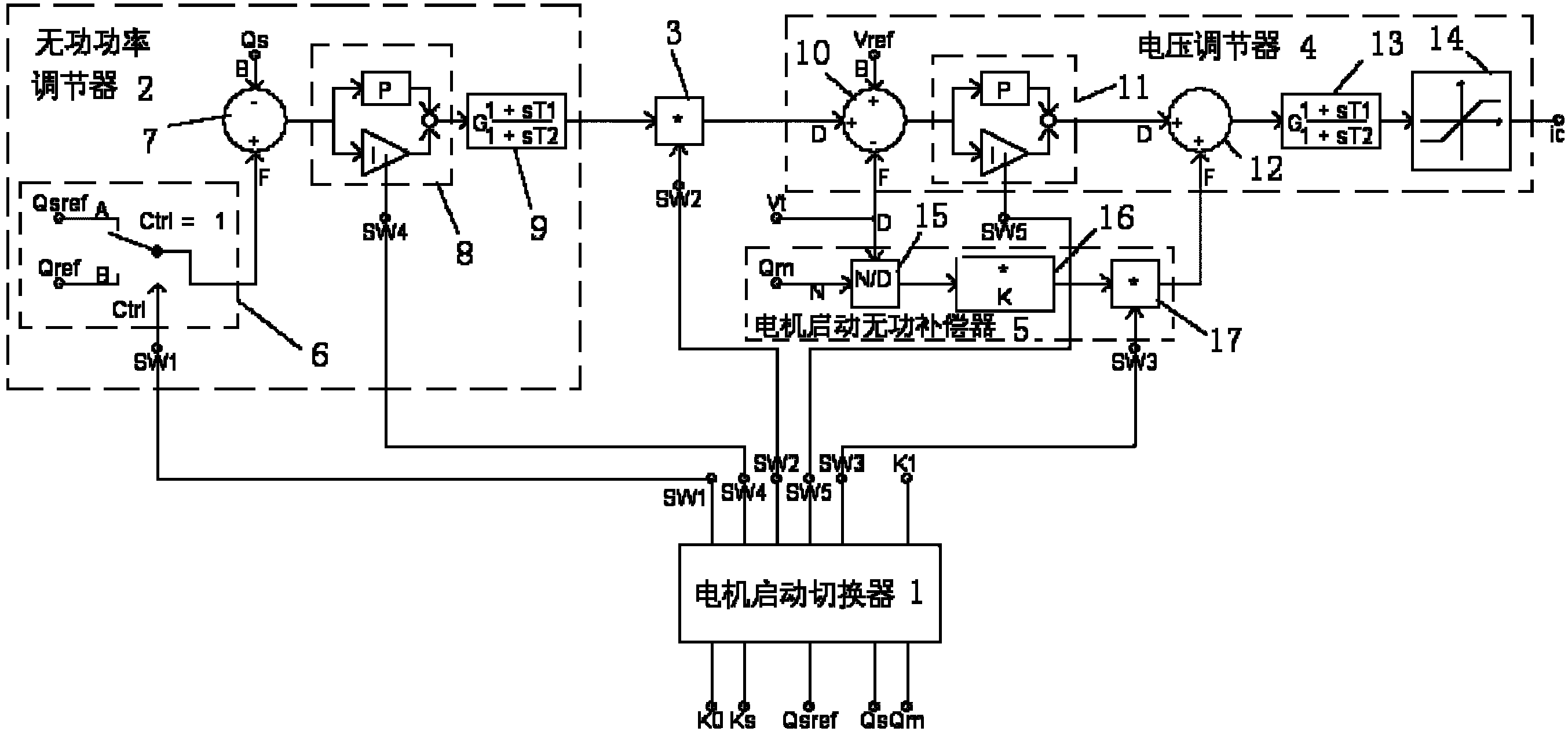

[0031] Embodiment 1: as figure 2 As shown, for a small power grid with a large asynchronous motor directly started, the dynamic reactive power compensator control and control method of the present invention will be designed and implemented according to the following steps:

[0032] 1) Capacity design of dynamic reactive power compensator. Firstly, determine the reactive power demand for direct start-up of large asynchronous motors. Generally speaking, the reactive power absorbed by the large asynchronous motors can reach 5 to 7 times the rated power (some asynchronous motors may even reach 8 to 10 times the rated power). The specific parameters are related to the load conditions. The maximum reactive power demand for motor startup in practical applications can be determined by several methods such as on-site testing, simulation analysis, and approximate estimation.

[0033] In the present invention, the reactive power adjustment range of the dynamic reactive power compensato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com