Angle drive components

A technology of angular transmission and components, applied in the direction of transmission, gear transmission, vehicle parts, etc., can solve the problems of hindering the expansion of angular transmission parts, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

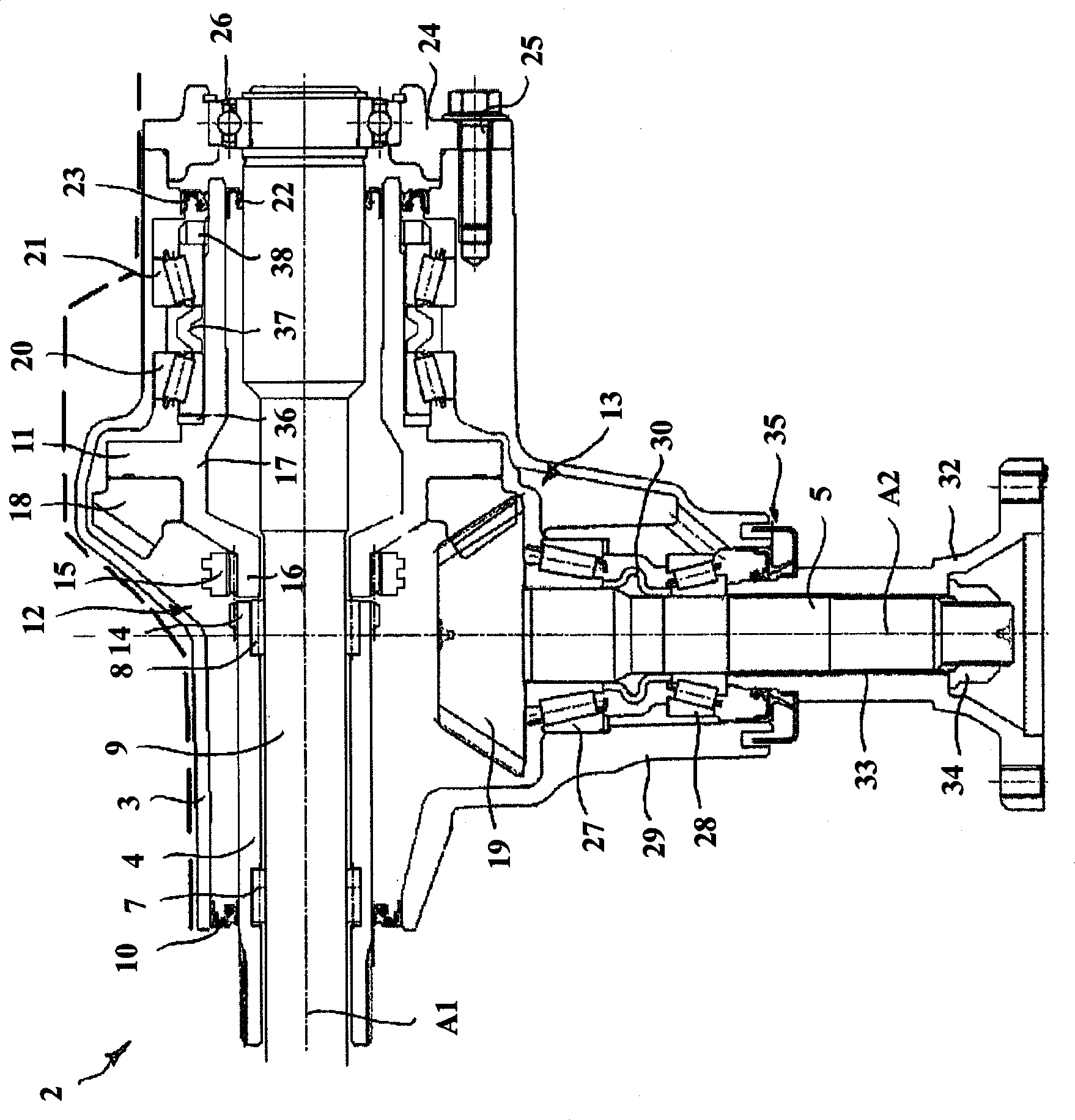

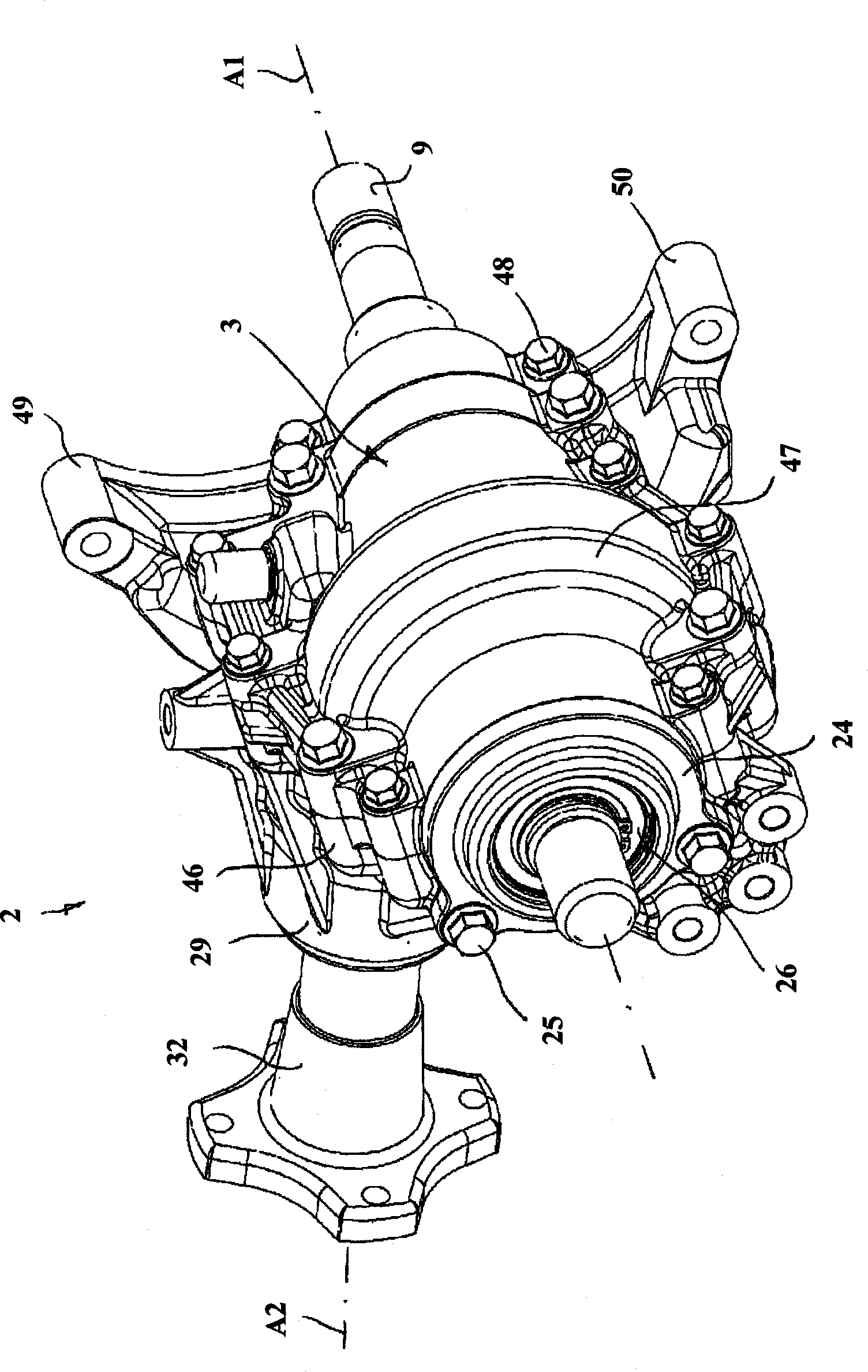

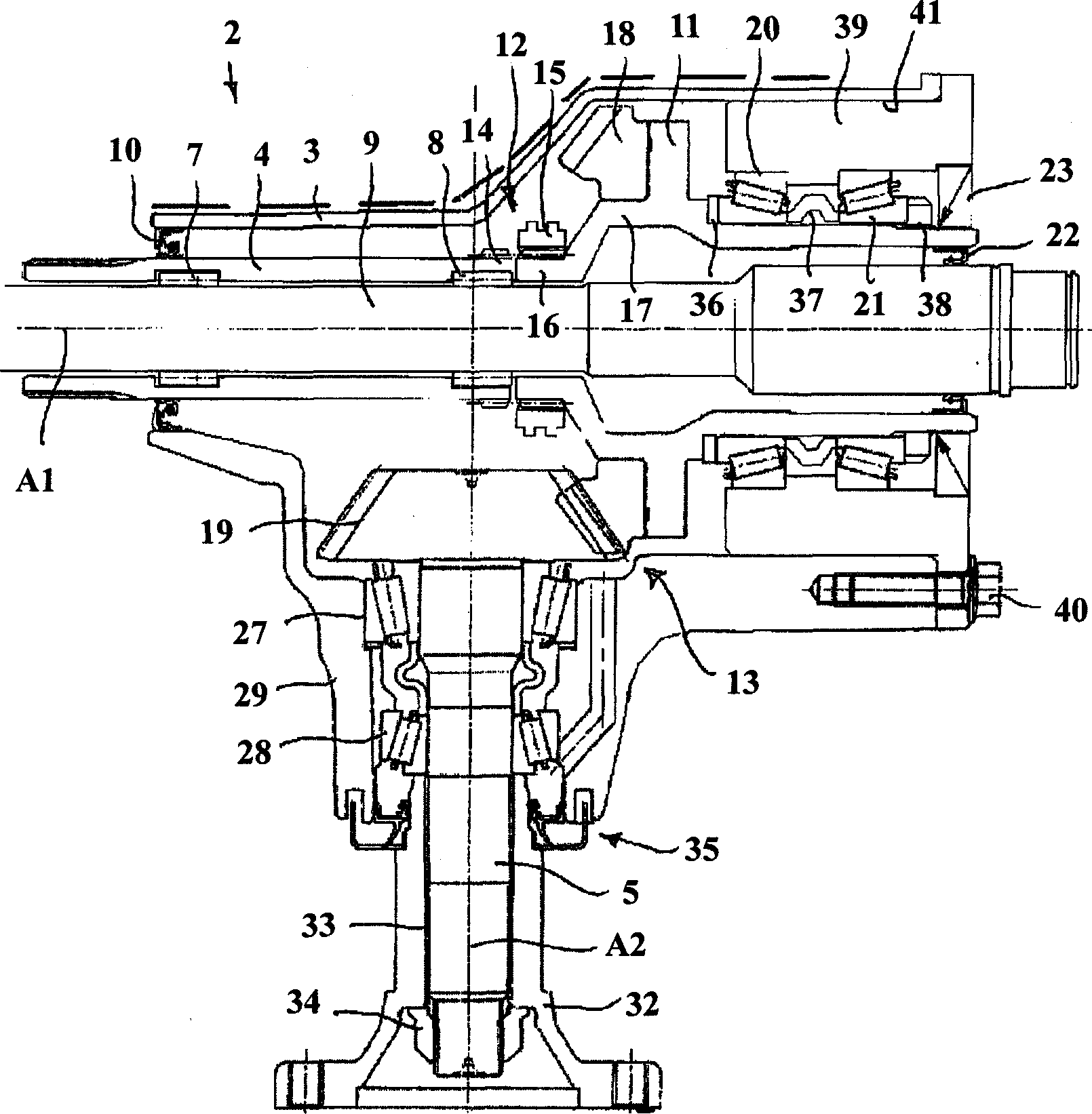

[0026] The following first jointly describe Figures 1 to 6 . The angular transmission assembly 2 comprises a casing 3, an input shaft 4 mounted in the casing 3 in a manner rotatable about a first axis of rotation A1, and an input shaft 4 mounted in the casing 3 in a manner rotatable about a second axis of rotation A2. Output shaft 5. The second axis of rotation A2 intersects the first axis of rotation A1 at a distance at right angles. The housing 3 has a coupling flange, not shown here, with which the angle drive assembly can be screwed to a stationary component, in particular to a differential, or to a motor component place. The input shaft 4 is designed in the form of a hollow shaft and has a shaft engagement at its free end for rotationally fixed contact with drive components not shown here, in particular with the differential carrier of the differential. connected.

[0027] It can be seen that the input shaft 4 is mounted rotatably about the axis of rotation A1 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com