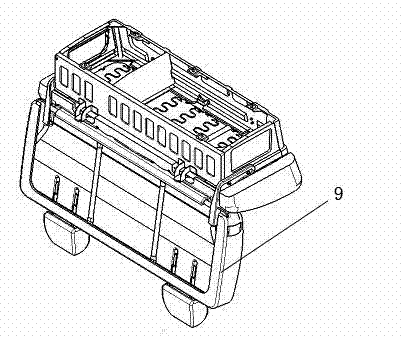

Interior tool box for truck

A toolbox and truck technology, applied in the field of toolbox structure installed on the vehicle, can solve the problems of poor molding process, high toolbox cost, poor airtightness, etc., and achieves high airtightness and moisture resistance, strong space adaptability, convenient The effect of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

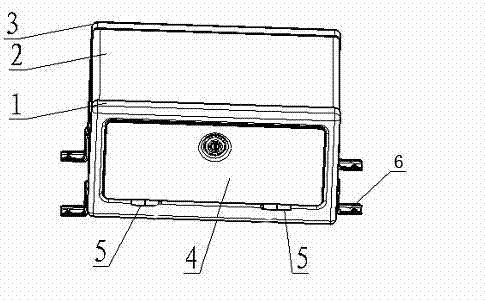

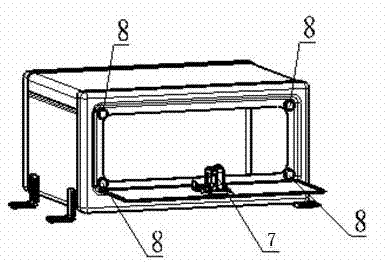

[0019] see figure 2 , the overall approximate box shape of the toolbox, the toolbox body is independent, including box frame 2, rear box plate 3 and front door frame 1 and box door 4 four parts. see Figure 4 , The box frame body 2 is a rectangular frame with front and rear openings. The rear box plate 3 is welded behind the box frame body to seal the rear opening. The front door frame 1 is a square frame welded to the front opening of the box frame body. Lockset 7 is installed, and locks with front door frame. A buffer block 8 is provided at the position where the front door frame 1 contacts with the box door when it is closed. The whole tool box body is installed on the floor of the truck through four mounting brackets 6. The mounting brackets 6 are L-shaped, arranged symmetrically at the bottom of both sides of the box frame body 2, connected by welding, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com