Anti-tipping control method, device and system and engineering plant

A technology of construction machinery and control devices, which is applied to cranes and other directions, can solve the problems of construction machinery overturning and overweight hanging objects, and achieve the effect of avoiding overturning accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and in combination with the application of a crane in construction machinery as an example.

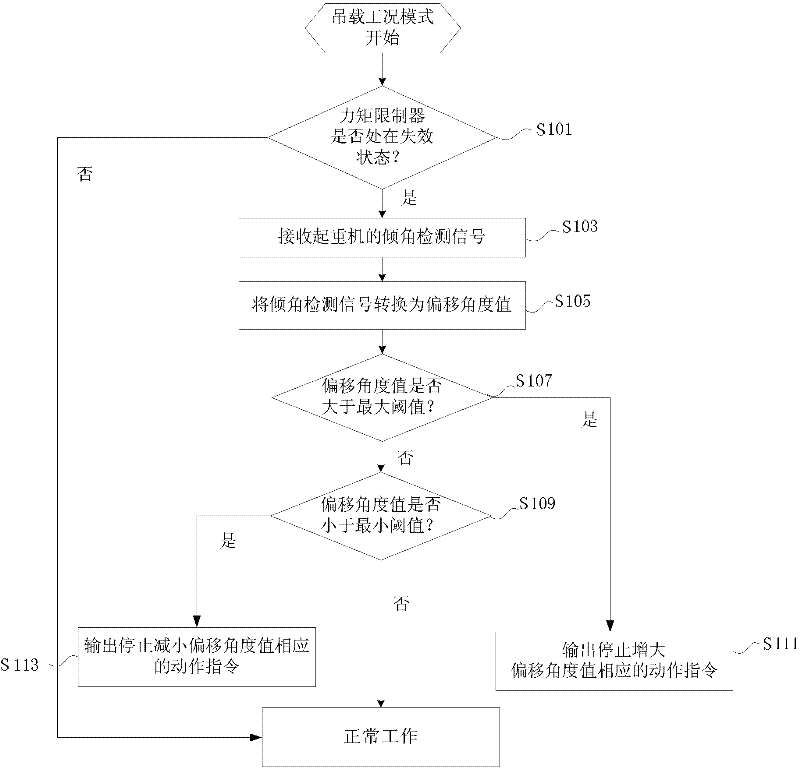

[0020] figure 1 is a flowchart of the main steps of Embodiment 1 of the anti-rollover control method according to the embodiment of the present invention, and, figure 1 It shows the main steps of the anti-overturning control method of the present invention when the crane is in the hoisting mode, as figure 1 As shown, the method mainly includes the following steps:

[0021] Step S101: Determine whether the moment limiter of the crane is in an invalid state, if so, execute step S103, otherwise the crane is in a normal working state under the hoisting working mode.

[0022] During the working process of the crane in i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com