Heat treatment technology method for improving obdurability of high-speed steel

A process method and technology of strength and toughness, applied in the field of heat treatment of high-speed steel parts, can solve the problems of not having both strength and toughness, not having the best comprehensive performance, etc., so as to achieve the change of strength and toughness, the improvement of mechanical properties, and the improvement of service performance. and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The stirring head made of W6Mo5Cr4V2Al high-speed steel is preheated by spheroidizing annealing on the material blank. The method is: heating to 950°C and keeping it for 1-2h, then lowering it to 740-780°C and keeping it for 3-5h, and finally cooling it to 550°C out of the furnace air cooled. After the main mechanical processing and forming are completed, the final heat treatment is carried out: preheating at 850-900°C, heating to 1230°C for austenitization, transferring to the lower bainite transformation temperature of 230-250°C for 1-1.5 hours, oil quenching; Then undergo cryogenic treatment at -160~-190°C for 24 hours, and then undergo secondary cycle treatment: heat preservation at 550~570°C for 1 hour, oil cooling to room temperature + cryogenic treatment; finally tempering at 550~570°C for 1~2 hours.

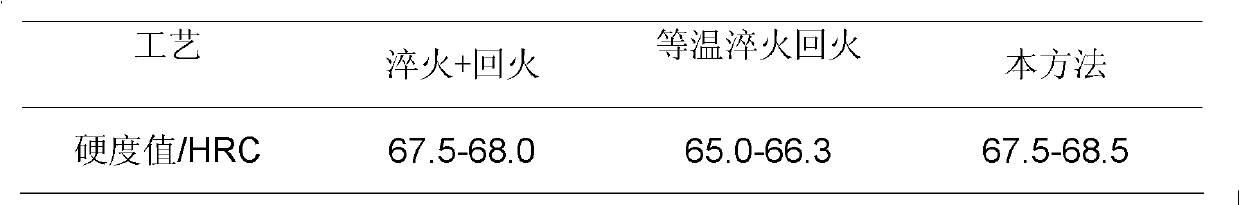

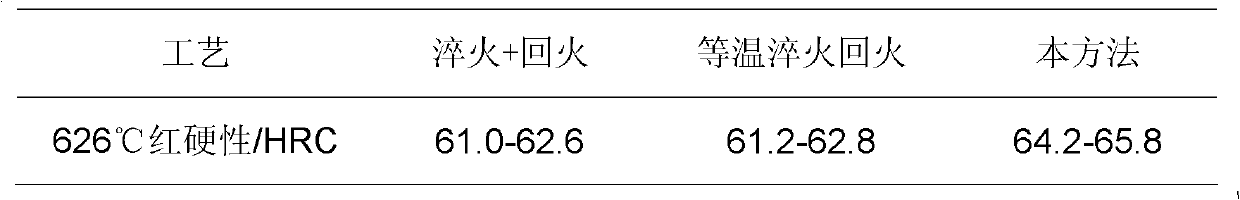

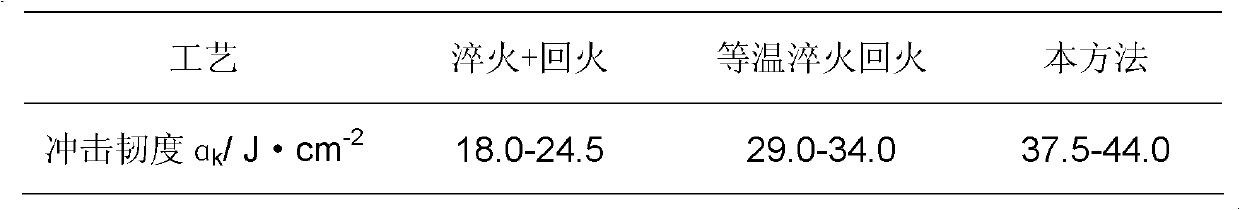

[0018] The technical parameters of the obtained W6Mo5Cr4V2Al high-speed steel stirring head mechanical properties and service performance are as follows:

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com