Passive locking hydraulic system

A hydraulic system, passive lock technology, applied in the direction of fluid pressure actuating system components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problem that the locking circuit cannot be implemented, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0015] Under the action of external load, the hydraulic system uses the function of system pressurization to close and negative pressure to open to position the piston of the hydraulic cylinder and complete the hydraulic locking function.

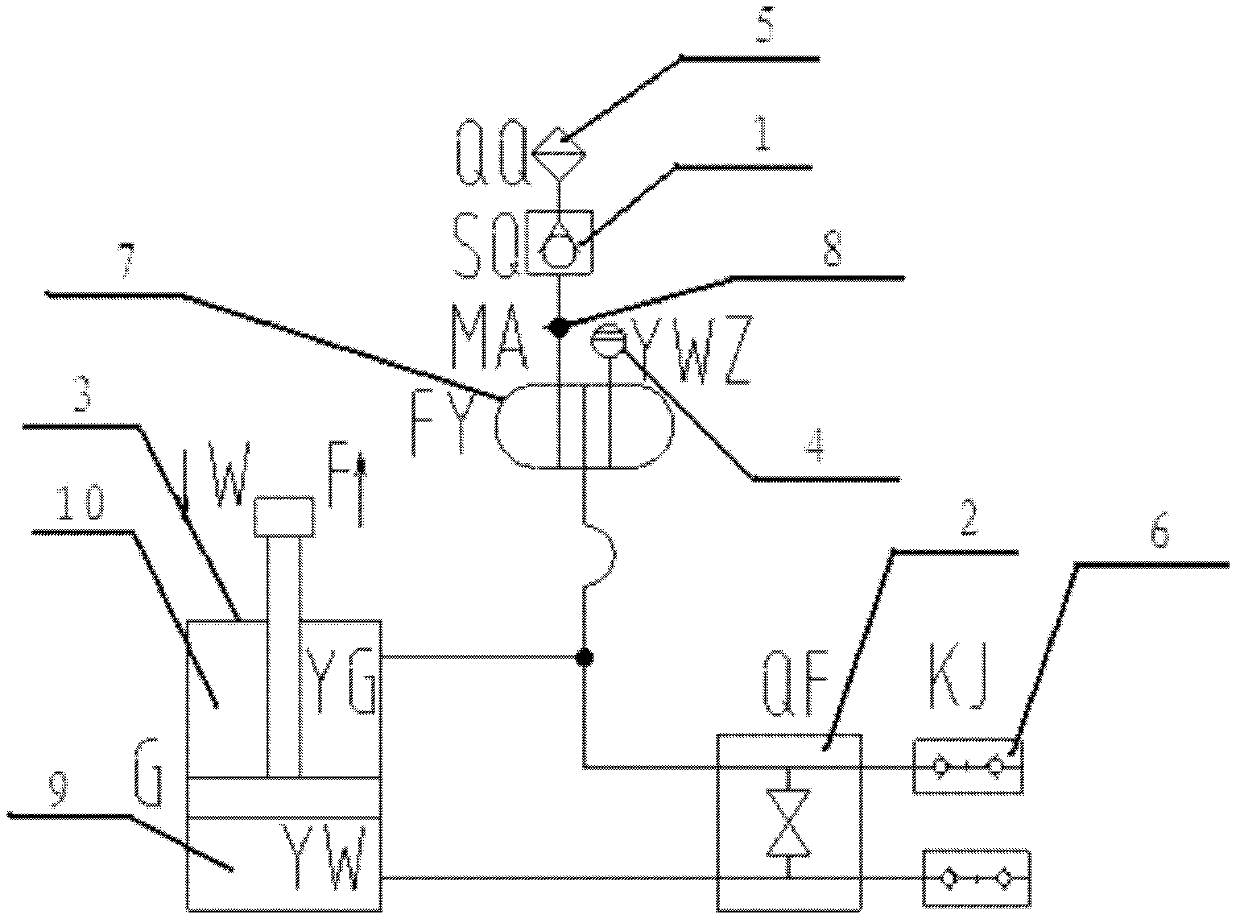

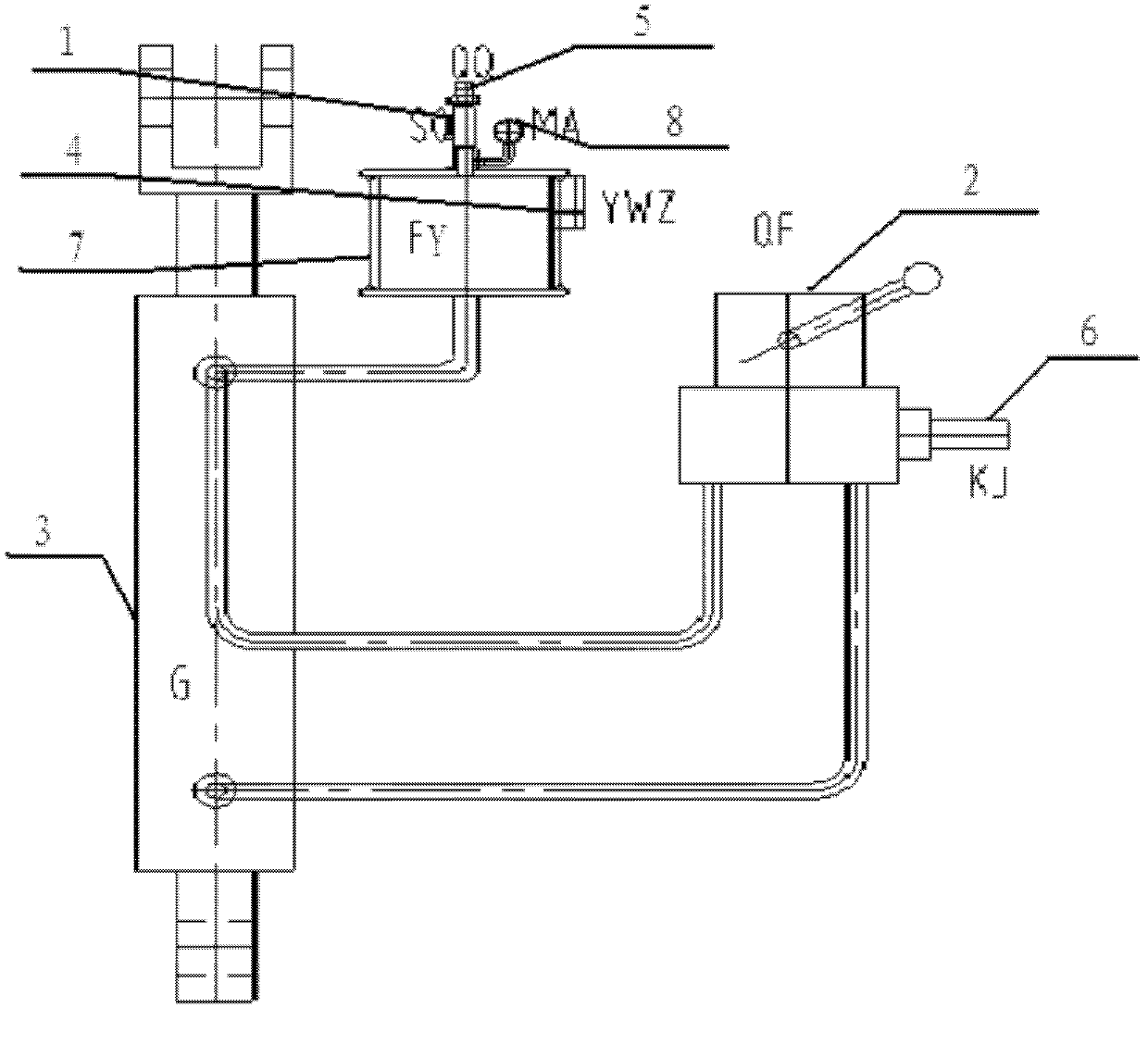

[0016] Such as figure 1 , figure 2 As shown, including SQ one-way valve 1, QF manual stop valve 2, G hydraulic cylinder 3, YWZ liquid level gauge 4, QQ air filter 5, KJ quick-change joint 6, FY replenishment tank 7, MA pressure measuring point 8 , the two KJ quick-change joints 6 are connected to the QF manual shut-off valve 2 through pipelines, and the KJ quick-change joint 6 is the system oil injection port, and the system mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com