Color glaze mobile phone housing or protective housing and manufacturing method thereof

A technology of mobile phone shell and manufacturing method, which is applied in the direction of telephone structure, special decorative structure, decorative art, etc., can solve the problems of high production cost, unable to form glaze layer, complex layered structure, etc., and achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

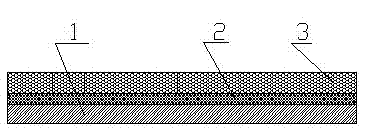

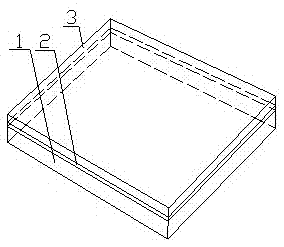

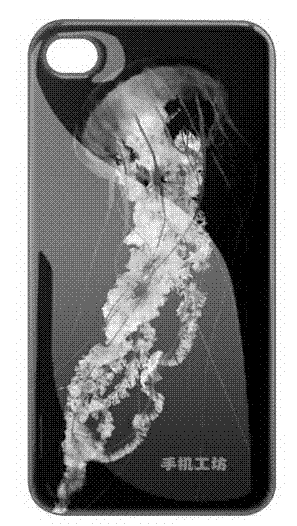

[0012] Example 1: refer to the attached Figure 1-4 . A colored glazed mobile phone case or protective case, which includes a mobile phone case 1 or a protective case, the manufacture of the mobile phone case 1 or the protective case is in the prior art, and will not be described here. A layer of painted layer 2 is placed on the surface of the mobile phone case 1 , and a layer of glaze layer 3 is placed on the painted layer 2 . The thickness of the glaze layer is less than 1.2mm, more than 0.6mm, and preferably 1mm.

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, a method for making a colored glazed mobile phone case or protective case, on the mobile phone case, any color pattern is attached to the surface of the mobile phone case by computer-aided design technology and manufacturing technology, and then by The special process attaches the 0.6mm ~ 1.2mm thick glaze and the corresponding liquid to the drawing layer, and at the same time, the liquid is cured to achieve the transparent and glossy effect of the glaze, and the wear resistance and adhesion fully meet the industrial standards. The liquid is a photo-solidification liquid, and the solidification method of the photo-solid liquid is in the prior art and will not be described here. The special process refers to manual glaze spraying, mechanical spraying glaze, electrostatic spraying glaze, manual glaze spraying, mechanical spraying glaze, electrostatic spraying glaze technology is the prior art, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com