Treatment method of rhodamine b dye wastewater

A dye wastewater and treatment method technology, which is applied in the field of rhodamine B dye wastewater treatment, can solve the problems of microbial poisoning and limit the application of bioremediation technology, and achieve the effects of reducing toxicity, easy control of reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

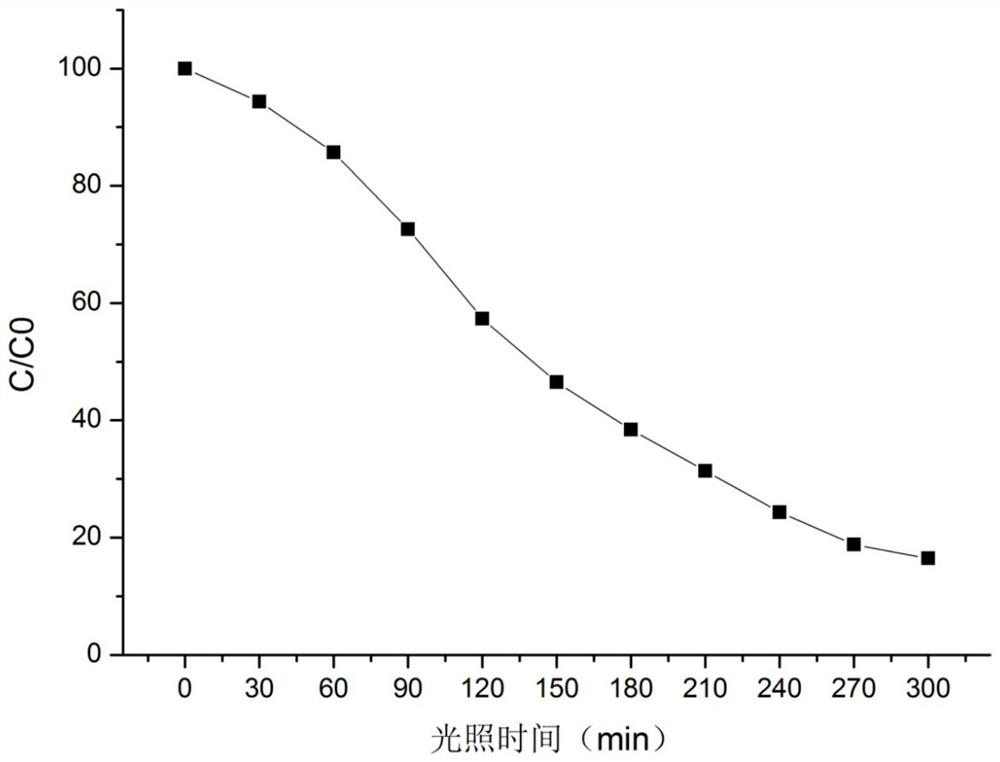

[0028] A treatment method for rhodamine B dye wastewater, comprising the following steps:

[0029] a. Add 1ml of compound degradation agent to 100ml concentration of Rhodamine B waste water of 20mg / L, and add the required nutrient solution of Nitrobacter victoria (containing glucose 10mg / mL, yeast extract 5mg / mL, peptone 10mg / mL) mL, potassium dihydrogen phosphate 0.5mg / mL, magnesium sulfate 0.5mg / mL), the dye concentration in the wastewater at this time is recorded as C 0 .

[0030] Wherein, composite degradation agent adopts following method to prepare:

[0031] (1) Preparation of nano bismuth tungstate:

[0032] (1.1) Dissolve bismuth nitrate pentahydrate and sodium tungstate dihydrate in a mixed solution of water and ethylene glycol to obtain a bismuth tungstate precursor solution, wherein bismuth nitrate pentahydrate, sodium tungstate dihydrate, ethylene glycol and The ratio of water is 0.2mmol: 0.1mmol: 1mL: 0.5mL; transfer the obtained bismuth tungstate precursor sol...

Embodiment 2

[0040] A treatment method for rhodamine B dye wastewater, comprising the following steps:

[0041] a. Select dye wastewater from a printing and dyeing factory in Jiangyin City, Jiangsu Province. The main pollutant of the dye wastewater is rhodamine B. After testing, the concentration of rhodamine B exceeds 120mg / L. The dye wastewater is diluted to a concentration of rhodamine B of 20mg / L.

[0042] b. add composite degradation agent in the Rhodamine B dye wastewater after above-mentioned dilution in the ratio of 1.5: 100 by the volume ratio of composite degradation agent and diluted Rhodamine B dye wastewater, and add the required nutrition of Nitrobacter victoria solution (containing glucose 15g / L, yeast extract 10g / L, peptone 15g / L, potassium dihydrogen phosphate 0.5g / L, magnesium sulfate 0.5g / L), the dye concentration in the wastewater at this time is recorded as C 0 .

[0043] Wherein, composite degradation agent adopts following method to prepare:

[0044] (1) Preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com