A kind of functional ceramics and its production equipment and production method

A technology of production equipment and production method, which is applied in the field of functional ceramics and its production equipment, can solve problems such as gaps, affecting the integrity of the overall aesthetic glaze coating, etc., to reduce firing temperature, improve mechanical strength and chemical stability, The effect of expanding the firing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

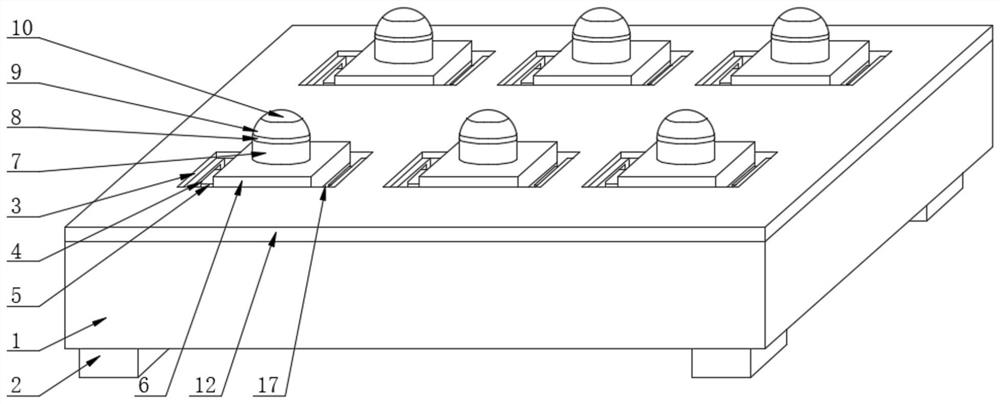

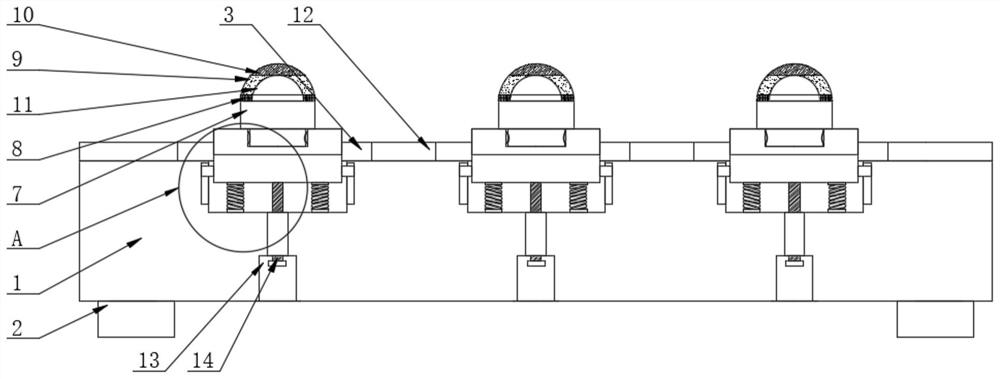

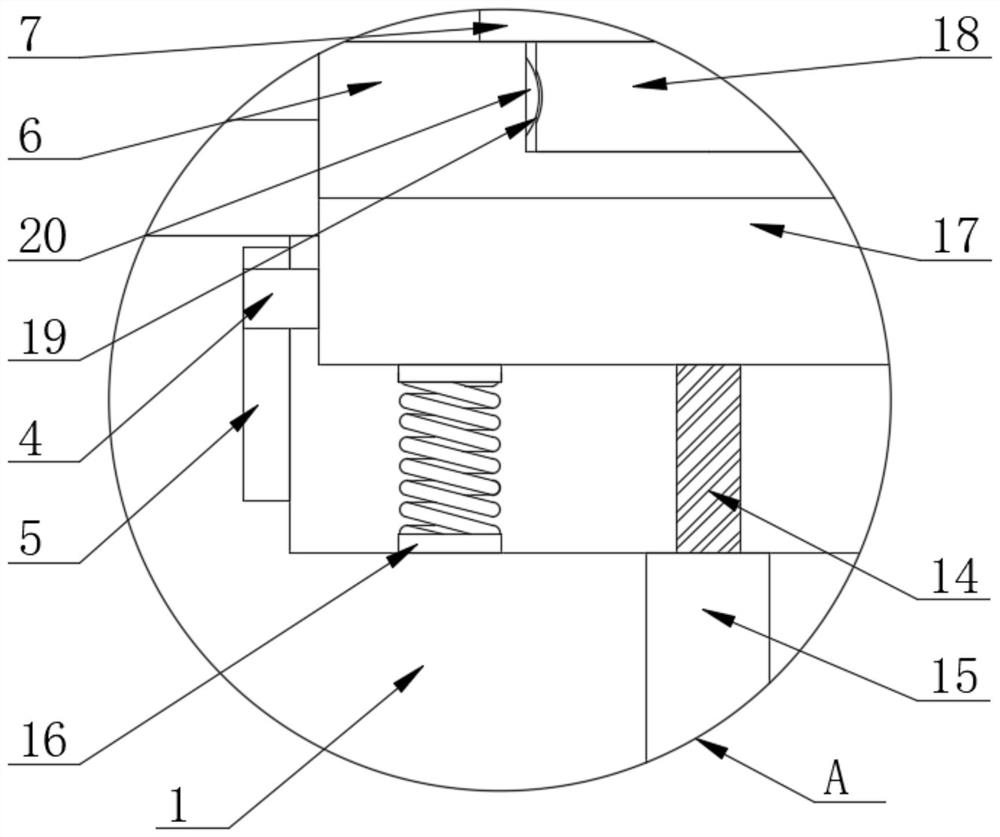

[0036] see Figure 1-4 , the present invention provides a technical solution: a functional ceramic production equipment, including a firing seat 1, the four corners of the bottom of the firing seat 1 are fixedly connected with support legs 2, and both sides of several inner cavities of the firing seat 1 are A chute 5 is provided, and a slide block 4 is slidably connected in the chute 5. By setting the slide block 4 and the chute 5, the lifting seat 17 is more stable through the sliding of the slide block 4 in the chute 5, and the lifting seat 17 is avoided. Offset shaking occurs, and a lift seat 17 is fixedly connected between the sliders 4 on both sides, and a spring 16 is fixedly connected to both sides of the bottom of the lift seat 17. By setting the spring 16, the spring 16 can use its own elastic force to pull the lift seat 17 Reset, so that when the threaded column 14 moves downward, the lifting seat 17 and the top support nail 9 can be driven to reset, the bottom of th...

Embodiment 2

[0047] Different from Example 1, the present invention provides a functional ceramic prepared from the following components in parts by weight: 60 parts of kaolin, 70 parts of quartz, 60 parts of dolomite, 50 parts of bentonite, 10 parts of calcium carbonate 5 parts, 5 parts of yttrium oxide, 10 parts of talcum powder, 20 parts of surfactant, 30 parts of functional particles;

[0048] The functional particles include tourmaline, woody stone mineralized balls and glass fibers, and the ratio of tourmaline, woody stone mineralized balls and glass fibers is 1:1:1, and the surfactant is an anionic and cationic dispersant .

[0049] A production method of functional ceramics, specifically comprising the following steps:

[0050] Step 1: Prepare ceramic green embryo, mix 60 parts of kaolin, 70 parts of quartz, 60 parts of dolomite, 50 parts of bentonite, 10 parts of calcium carbonate, 5 parts of yttrium oxide, and 10 parts of talcum powder by weight, wash and bake Dried to make chi...

Embodiment 3

[0056] Different from Example 1, the present invention provides a functional ceramic prepared from the following components in parts by weight: 50 parts of kaolin, 60 parts of quartz, 50 parts of dolomite, 40 parts of bentonite, 7 parts of calcium carbonate 3 parts of yttrium oxide, 7 parts of talcum powder, 15 parts of surfactant, 15 parts of functional particles;

[0057] The functional particles include tourmaline, woody stone mineralized balls and glass fibers, and the ratio of tourmaline, woody stone mineralized balls and glass fibers is 1:1:1, and the surfactant is an anionic and cationic dispersant .

[0058] A production method of functional ceramics, specifically comprising the following steps:

[0059] Step 1: Prepare ceramic green embryo, mix 50 parts of kaolin, 60 parts of quartz, 50 parts of dolomite, 40 parts of bentonite, 7 parts of calcium carbonate, 3 parts of yttrium oxide, and 7 parts of talcum powder by weight, wash and bake Dried to make china clay compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com