Compound degradation agent for degrading rhodamine B dye and preparation method of compound degradation agent

A degrading agent and dye technology, applied in chemical instruments and methods, water pollutants, water treatment of special compounds, etc., can solve the problems of microbial poisoning, limit the application of bioremediation technology, etc., and achieve the effect of reducing the poisoning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

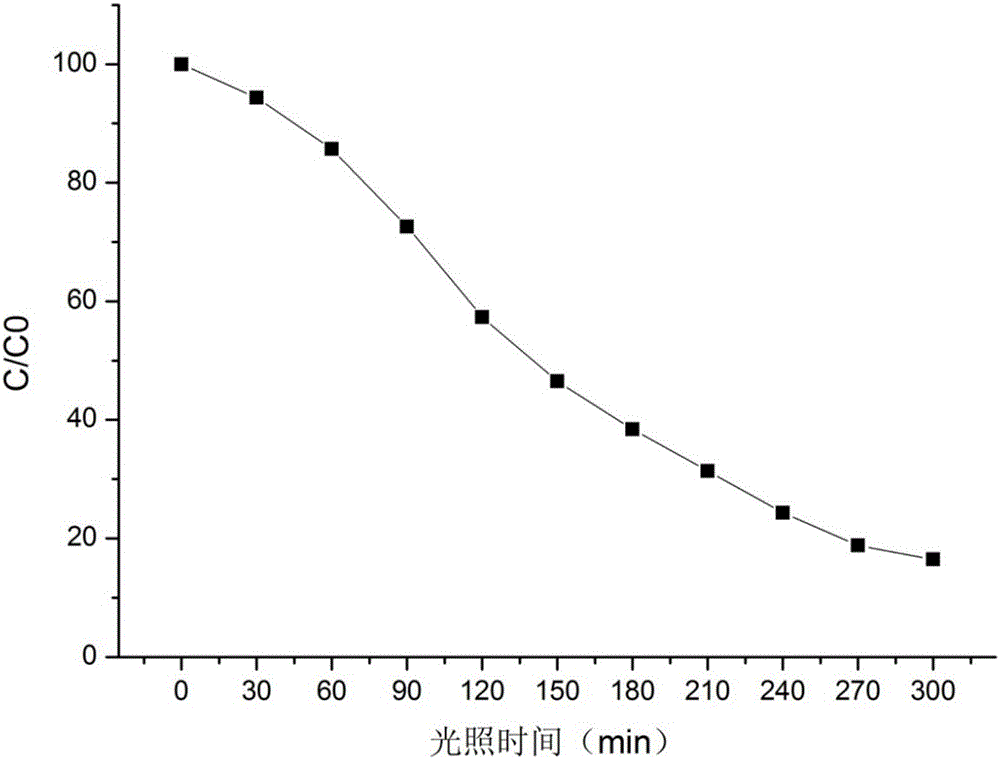

Image

Examples

Embodiment 1

[0026] A kind of preparation method of the composite degradation agent of the degradation rhodamine B dye of the present embodiment, comprises the following steps:

[0027] (1) Preparation of nano bismuth tungstate:

[0028] (1.1) Bismuth nitrate pentahydrate and sodium tungstate dihydrate are dissolved in a mixed solution of water and ethylene glycol to obtain a bismuth tungstate precursor solution, wherein the ratio of bismuth nitrate, sodium tungstate, ethylene glycol and water is 0.2mmol: 0.1mmol: 1mL: 0.5mL; transfer the obtained bismuth tungstate precursor solution into a hydrothermal reaction kettle for coordination polymerization reaction at a temperature of 160°C for 90h, centrifuge after the reaction is completed, and remove the precipitate washing and drying to obtain a coordination polymer;

[0029] (1.2) Put the coordination polymer obtained in step (1.1) into a muffle furnace, heat up to 600°C at a heating rate of 15°C / min for high-temperature heat treatment for...

Embodiment 2

[0038] A preparation method of a composite degrading agent for degrading Rhodamine B dye of the present embodiment, comprising the following steps:

[0039] (1) Preparation of nanometer bismuth tungstate:

[0040] (1.1) Dissolving bismuth nitrate pentahydrate and sodium tungstate dihydrate in a mixed solution of water and ethylene glycol to obtain a bismuth tungstate precursor solution, wherein the ratio of bismuth nitrate, sodium tungstate, ethylene glycol and water is 0.2mol:0.1mol:1L:0.5L; transfer the obtained bismuth tungstate precursor solution into a hydrothermal reaction kettle, and carry out a coordination polymerization reaction at a temperature of 160 °C and a time of 90 h. Wash and dry to obtain a coordination polymer;

[0041] (1.2) Put the coordination polymer obtained in step (1.1) into a muffle furnace, and heat it up to 600°C at a heating rate of 15°C / min for a high temperature heat treatment for 2.5h. Grind into powder to obtain nanometer bismuth tungstate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com