Steam sterilization apparatus

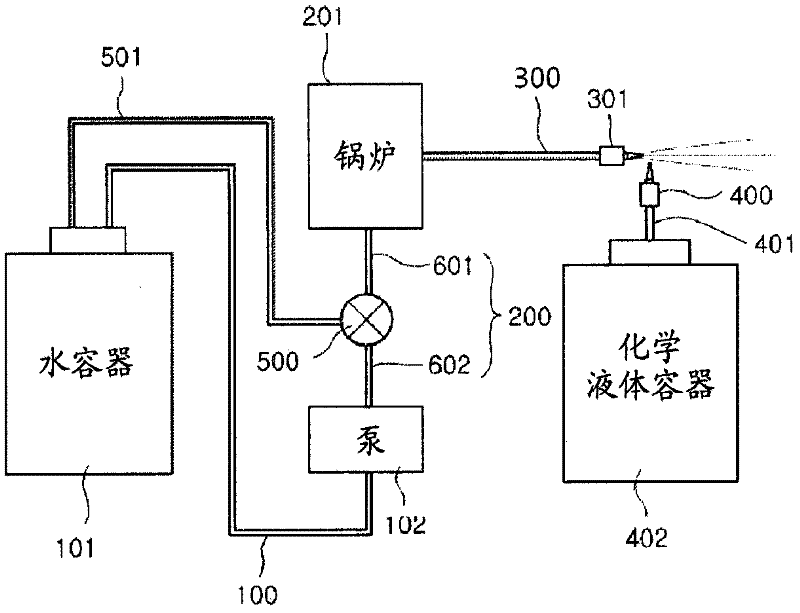

A disinfection device, steam technology, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of pump 102 damage, decrease in steam generation efficiency, large volume, etc., and achieve easy replacement or cleaning, easy to carry and move, The effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

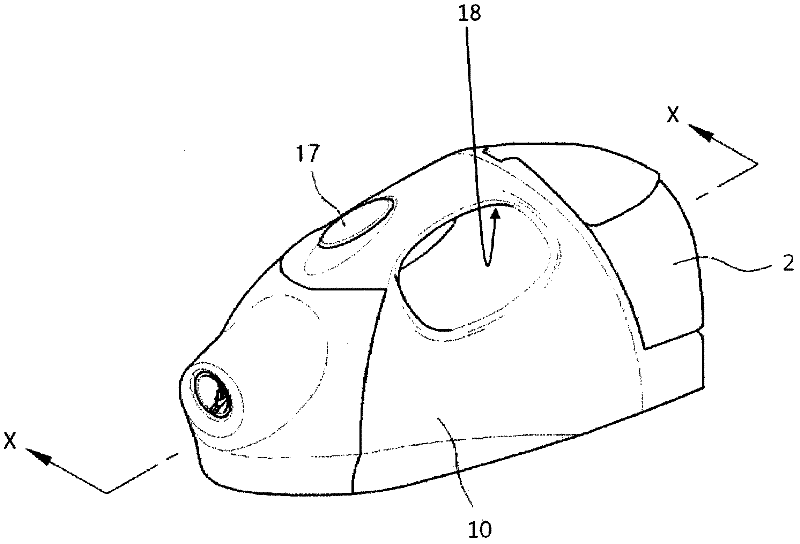

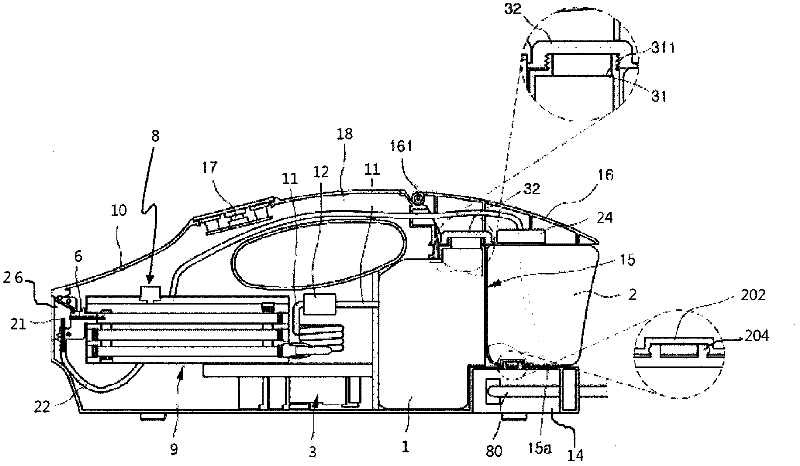

[0035] figure 2 is a perspective view of the external structure of the steam sterilizer according to the first example embodiment of the present invention, and image 3 is shown along figure 2 Cross-sectional view of the internal structure of the steam sterilizer taken along the line x-x shown.

[0036] refer to figure 2 with image 3 , the steam sterilizer according to the first exemplary embodiment of the present invention includes: a housing 10 forming a main body; a water container 1 disposed at the inner rear of the housing 10 to store water; a chemical liquid container 2 disposed at After the water container 1 to store the chemical liquid; the nozzle assembly 26 is arranged at the inner front of the housing 10 and includes the steam nozzle 6 and the chemical liquid nozzle 21, wherein the steam nozzle 6 is used to receive the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com