Automatic calibration method for sensor of breathing machine

An automatic calibration, ventilator technology, applied in the direction of respirator, machine/engine, test/calibration device, etc., can solve the problem of tedious calibration steps of ventilator, and achieve the effect of speeding up progress and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

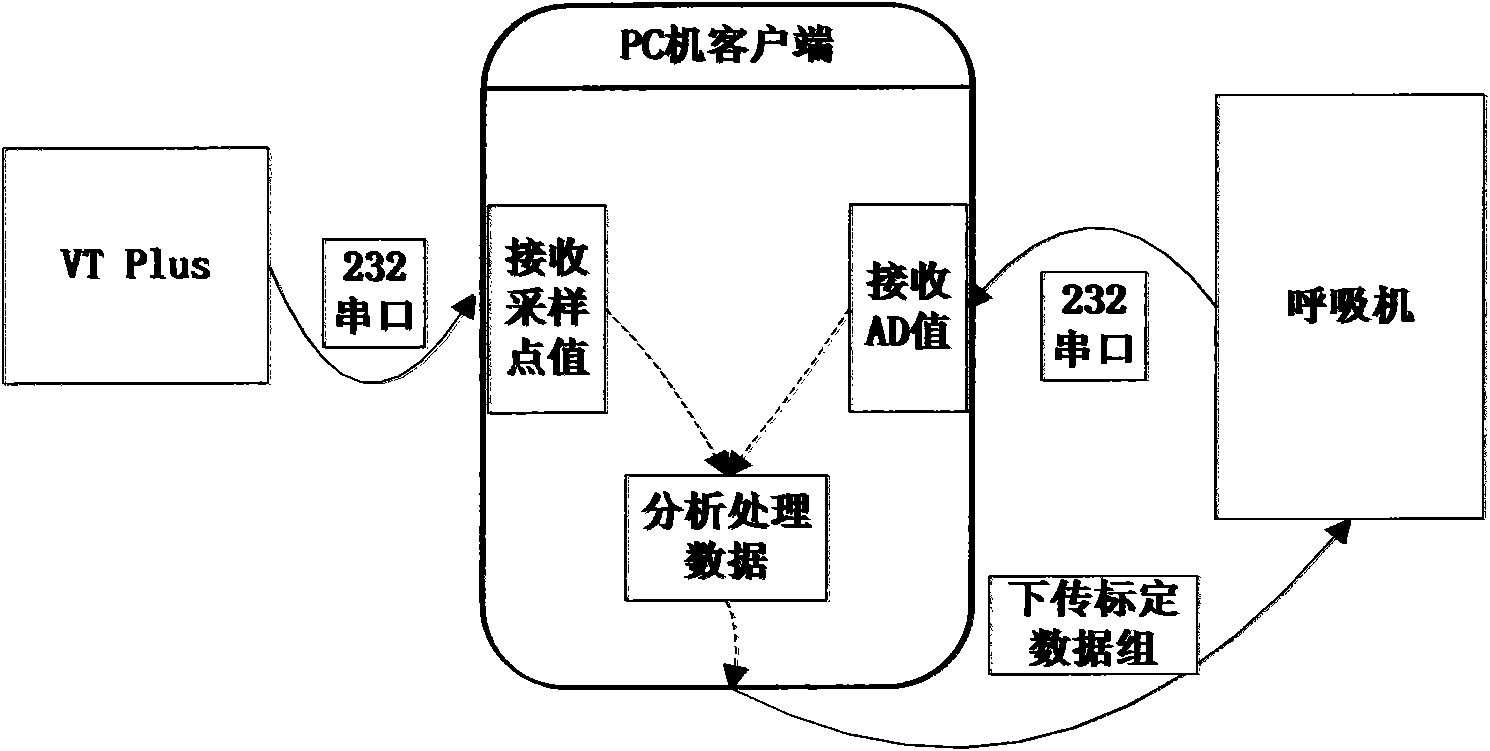

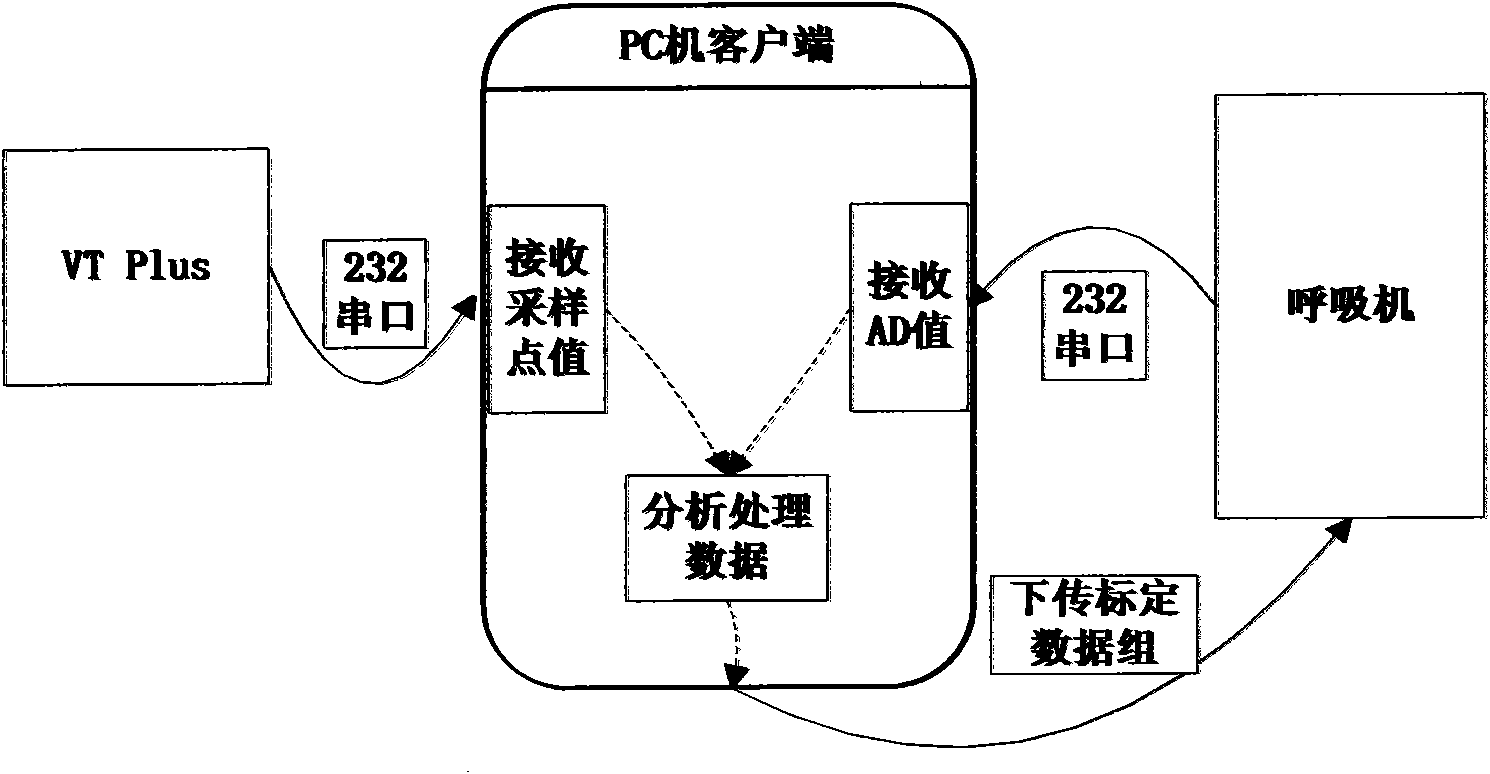

[0018] Such as figure 1 As shown, the equipment that the present invention needs to use includes computer, ventilator equipment to be calibrated and calibration air circuit, and airflow analyzer, wherein the computer can adopt common PC machine, and airflow analyzer can adopt the VT Plus airflow analysis of American Fluke Company instrument. Connect the airflow analyzer to the gas circuit of the ventilator, connect the airflow analyzer to the PC through the RS232 communication interface, and connect the ventilator to the PC through the RS232 communication interface.

[0019] The invention can realize the automatic calibration of the ventilator sensor, including the calibration of the pressure sensor and the flow sensor, as well as the calibration of the blower fan and the breathing valve.

[0020] When calibrating, set multiple data sampling points, and at each data sampling point, send a calibration command to the ventilator through the computer, and the gas flow analyzer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com