Dust removing box and dust removing system with same

A technology of dust removal box and box, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problem that the dust cannot fall smoothly, the filtering efficiency of the air filter cartridge is not ideal, and the dust removal efficiency of dry filtration is reduced. and other problems, to achieve the effect of reducing dust concentration and improving the efficiency of filtration and dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

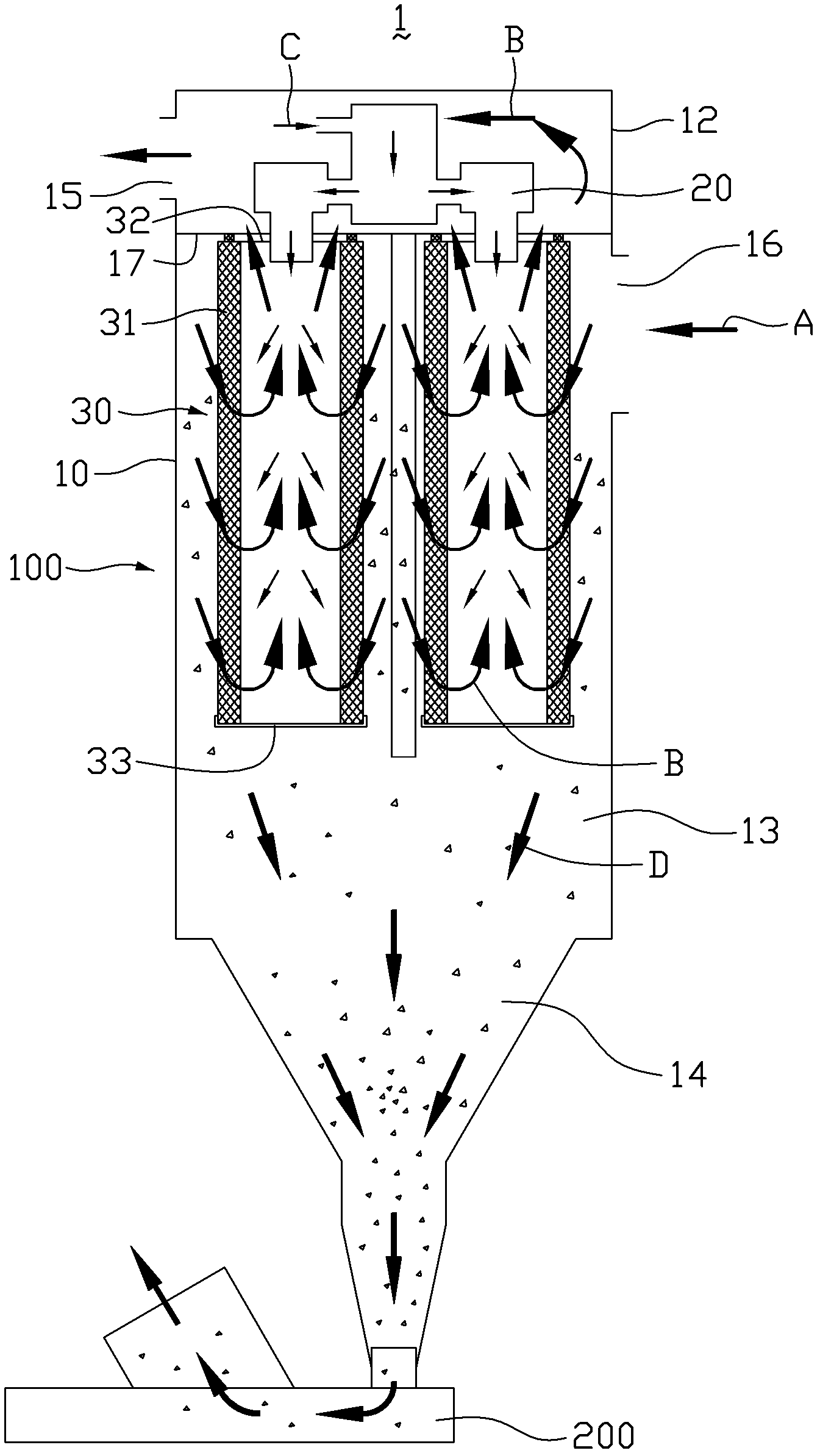

[0029] Please refer to figure 1 , The dust removal system 1 of the present invention can be applied to a dry dust removal road sweeper or a dust collector for filtering and removing dust from an airflow containing dust. The dust removal system 1 includes a dust removal box 100 and a suction nozzle 200 . The dust filtered by the dust removal box 100 is discharged to the dustbin through the suction nozzle 200 .

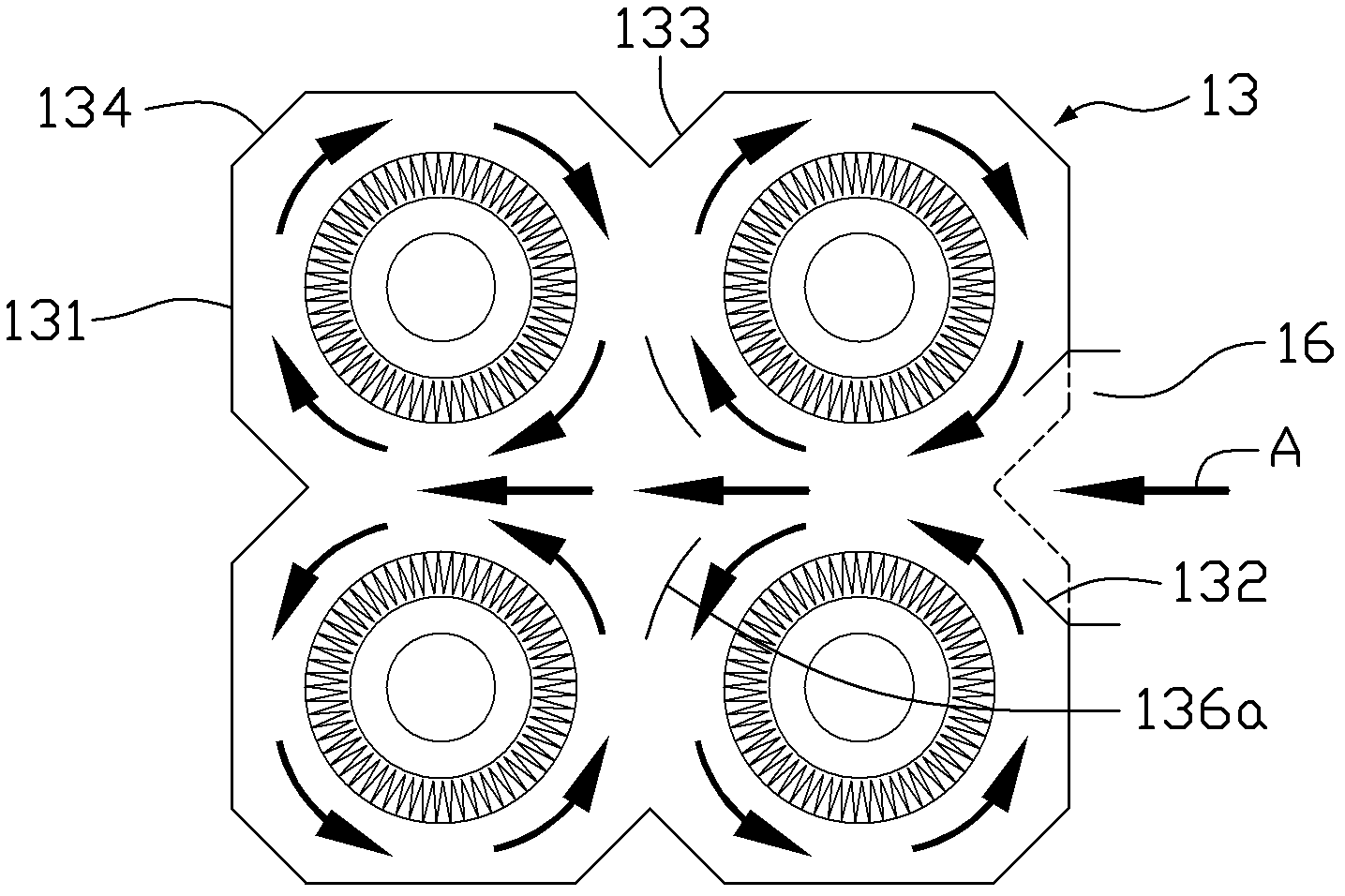

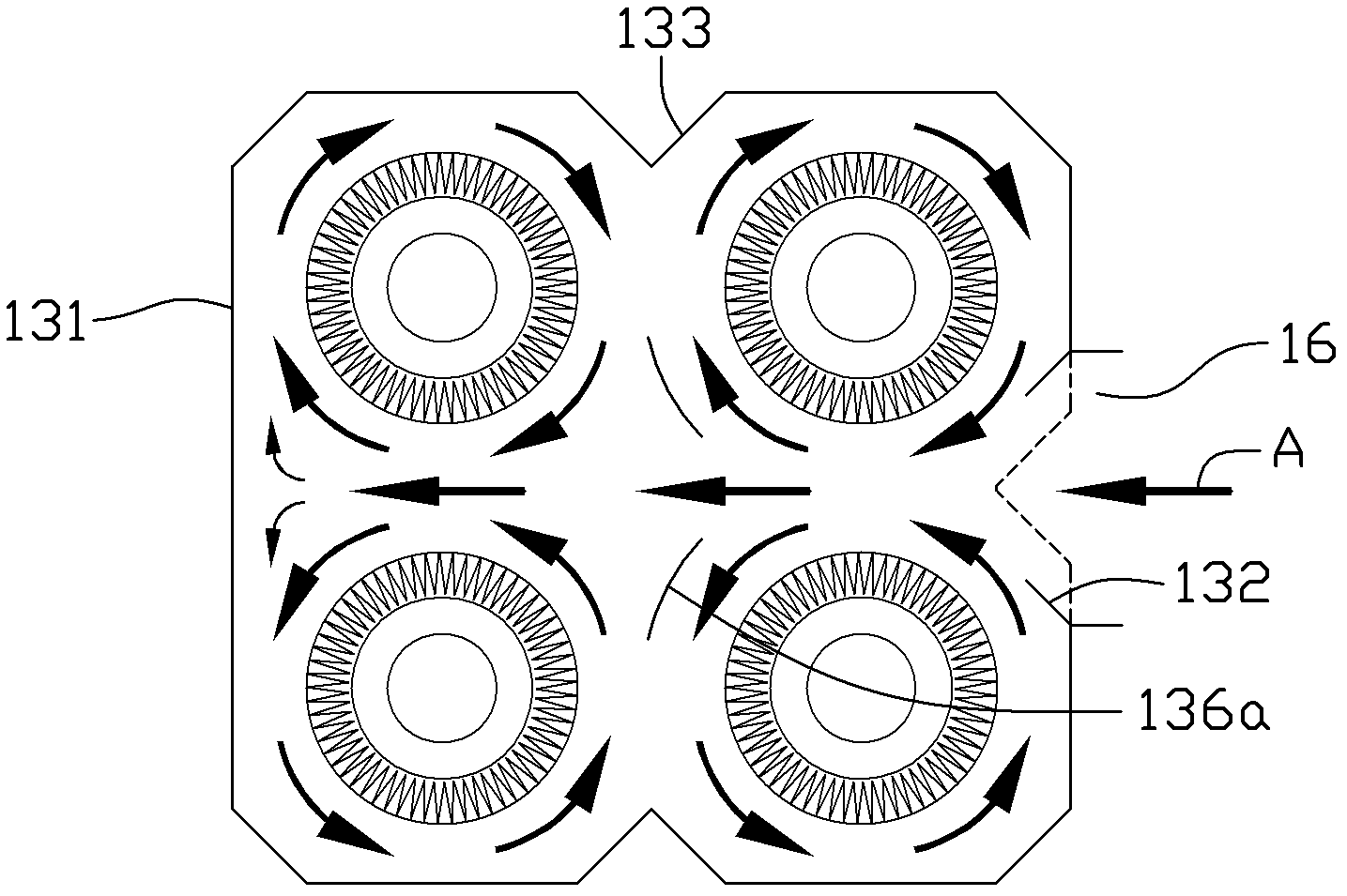

[0030] The dust removal box 100 includes a box body 10 , a high-pressure dust collector 20 and an air filter cartridge 30 . A partition 17 is arranged inside the box body 10 to divide the box body 10 into an upper box body 12 and a box body lower part 13 . The upper part 12 of the box body is provided with an exhaust port 15 , and the high-pressure dust collector 20 is installed on the upper part 12 of the box body. The air filter cartridge 30 can be detachably installed on the partition 17 , or installed on the lower part of the box 13 through a fixing device (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com