Water decanter

A decanter and water decanter technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of poor sewage treatment effect of decanters, achieve good sewage treatment effect, Precise effect of control of stop drain signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

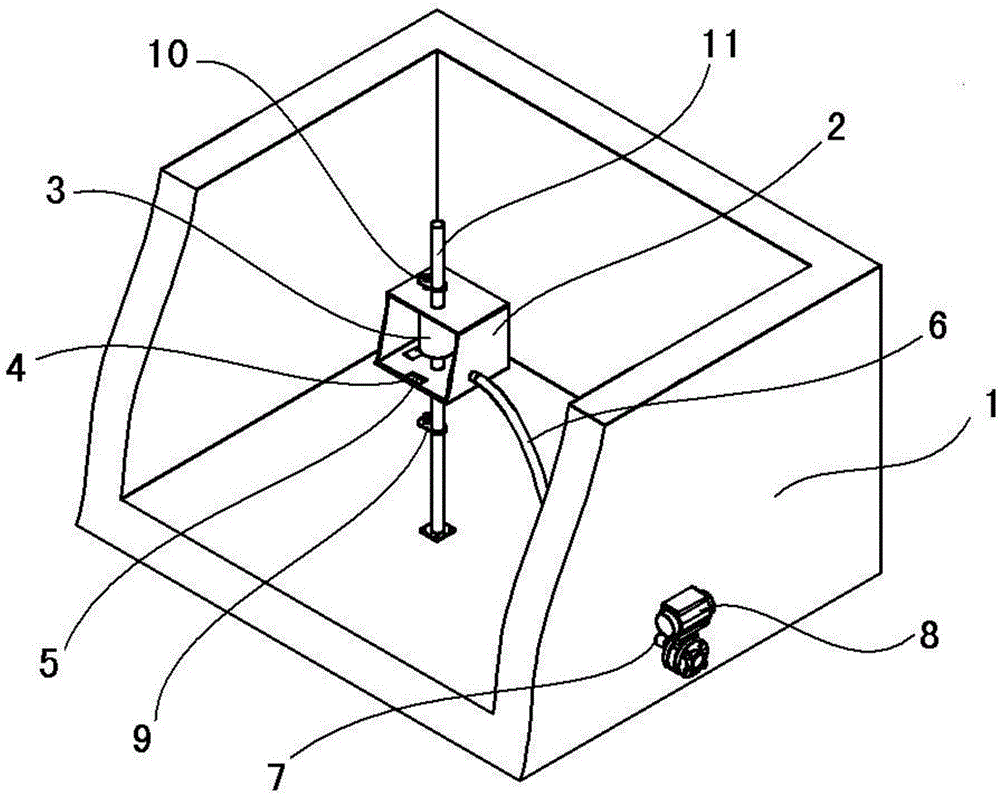

[0041] figure 1 It is a structural schematic diagram of a water decanter placed in a sewage treatment tank with a partial perspective of the weir housing provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the decanter provided in this embodiment includes: a decanting structure floating on the surface of the pool, and the decanting structure has a water collection area; a drain hose 6, one end communicates with the water collection area, and the other end It communicates with the drain port 7 on the pool wall, and a drain valve 8 is set on the decanting structure and / or the pool wall to control the drainage of the drain hose 6 or to close the drain; the downstroke switch 9 is fixedly installed in the pool and located on the On the moving path of the decanting structure as the liquid level drops, the downstroke switch 9 is electrically connected to the drain valve 8, and is triggered by the decanting structure when the liquid level drops and moves to ...

Embodiment 2

[0059] This embodiment provides a decanter as an alternative to the first embodiment. The difference between the decanter and the first embodiment is:

[0060] In the decanting structure of this embodiment, the float is arranged above the water collection weir, and the outer surface of the float and the upper surface of the water collection weir are provided with multiple sets of corresponding fixing rings. The water collecting weir is connected with the water collecting weir through the connecting chain arranged between each set of the fixing rings, so that the water collecting weir can float on the liquid surface along with the float.

Embodiment 3

[0062] This embodiment provides a decanter as an alternative to the first embodiment. The difference between the decanter and the first embodiment is:

[0063] The guide rail structure of this embodiment includes a plurality of guide columns arranged circumferentially around the decanting structure, the guide columns are arranged perpendicular to the bottom of the pool, and the shell surface of the water collection weir is correspondingly provided with a plurality of traction columns. The end of each traction chain is connected with a fixed ring, and the fixed ring is slidably sleeved on the guide column, so that the water collecting weir can be pulled by the traction chain and rise and fall with the liquid level. Move up and down along the axis of the guide column.

[0064] Both the upstroke switch and the downstroke switch are fixed on the moving path of the decanting structure along with the liquid level through a horizontal bracket parallel to the bottom of the pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com