A circular knitting machine for underwear

A technology for circular knitting machine and underwear, which is applied in the directions of weft knitting, knitting, and weft knitting circular knitting machines with separate action needles, etc., can solve the problems of reducing production efficiency, shortening production time, etc. The effect of reducing impurities and avoiding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

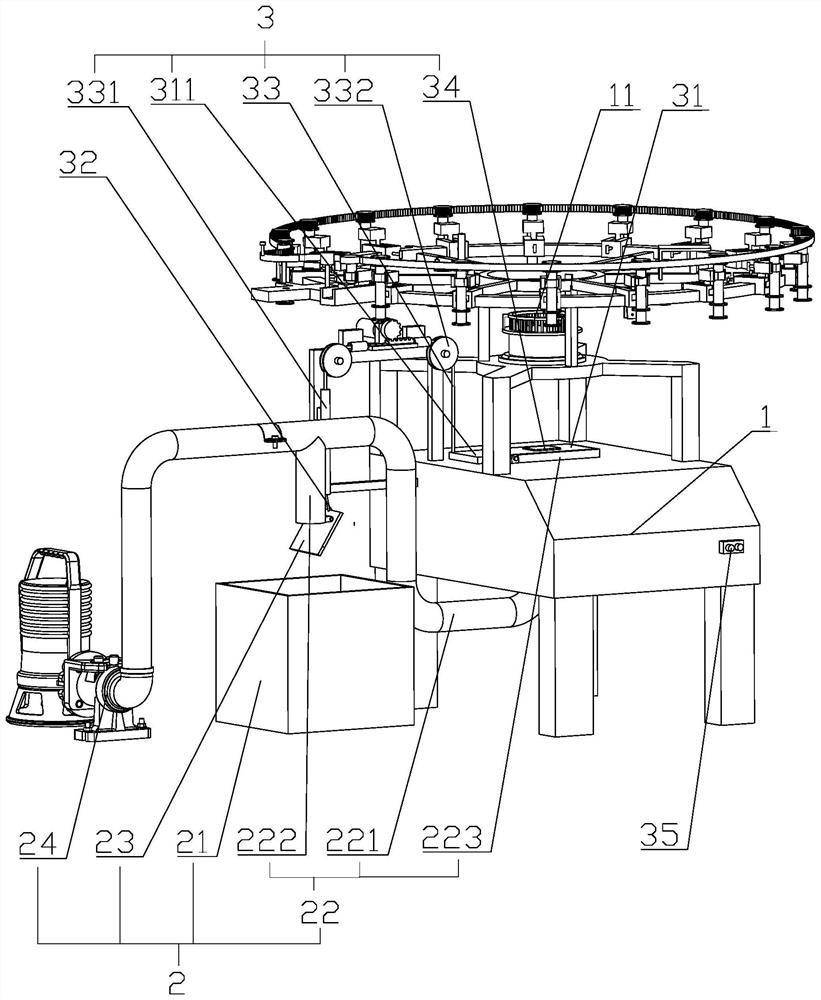

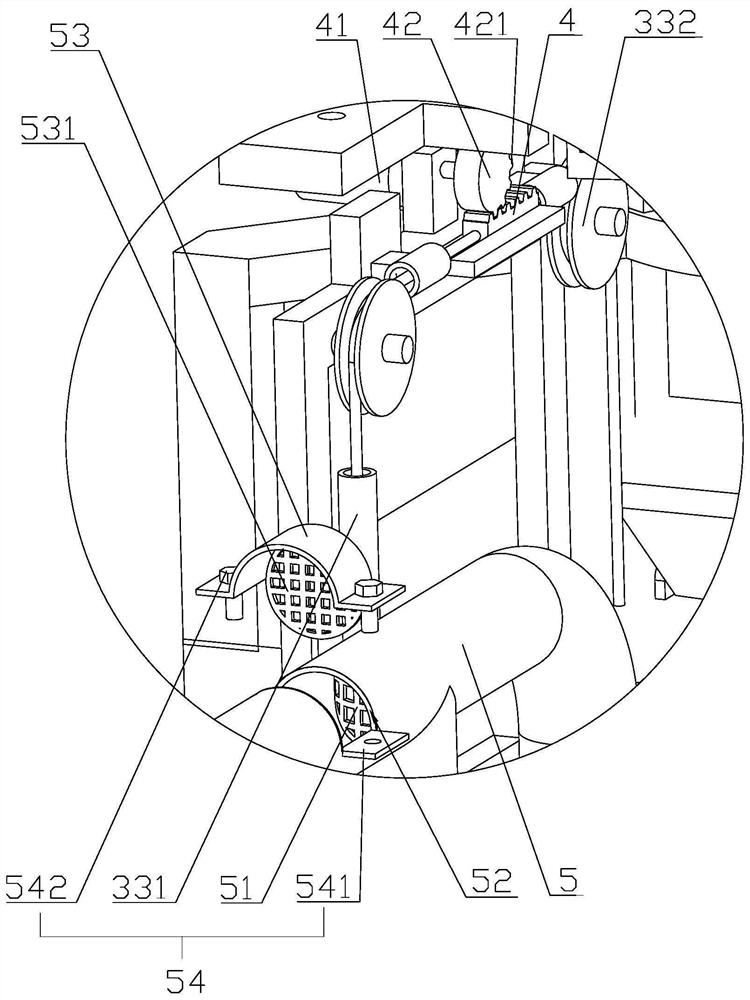

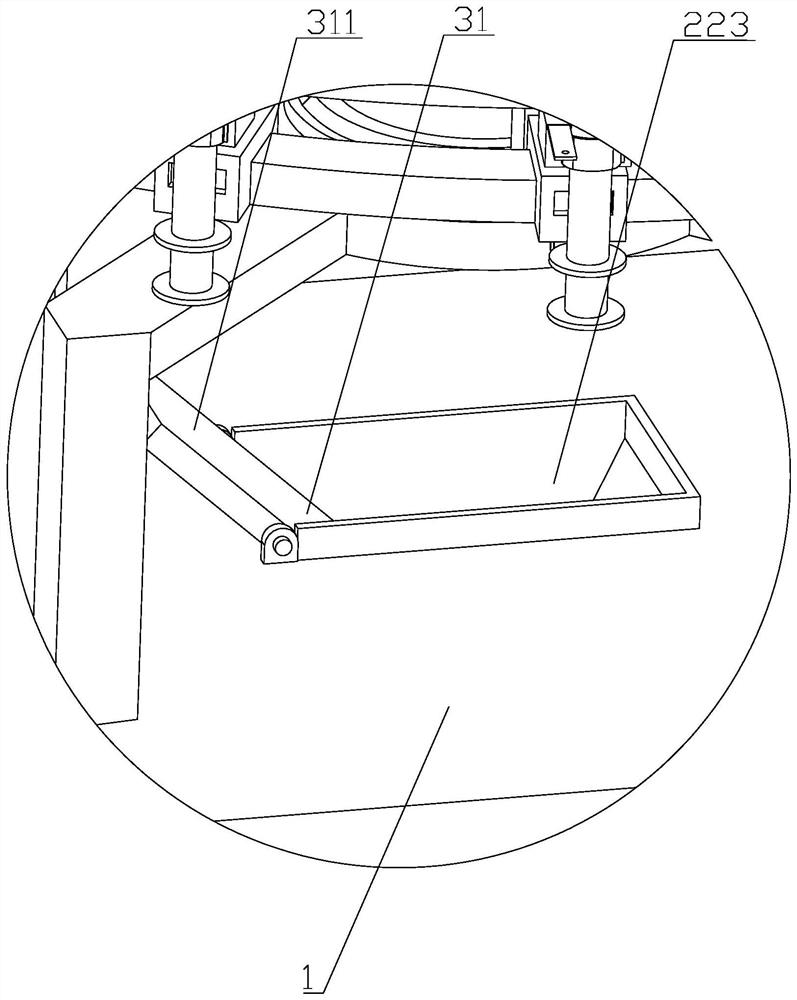

[0036] refer to figure 1 , is a circular knitting machine for underwear disclosed by the present invention, comprising a frame 1, and a receiving mechanism 2 arranged on the frame 1 below the needle cylinder 11, and the receiving mechanism 2 includes a A material receiving barrel 21, a suction pipe 22 with an opening at one end facing upwards, an end cover 23 set on the opening at one end of the suction pipe 22, a vacuum pump 24 arranged on one side of the frame 1 and the air inlet communicated with the suction pipe 22, As well as the driving assembly 3 provided on the frame 1 to open and close the opening of the feeding part 221 , the driving end cover 23 arranged on the frame 1 , the suction pipe 22 includes a feeding part 221 opposite to the syringe 11 , and a vertically arranged discharging part 222 .

[0037] The vacuum pump 24 is placed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com