While-drilling water plugging device for emergency rescue drilling

An emergency rescue, while drilling technology, which is applied to the drilling drive device in the wellbore, the valve device of the wellbore/well, and the drill pipe, etc., can solve the problem of low drilling efficiency, etc. Plugging effect, less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

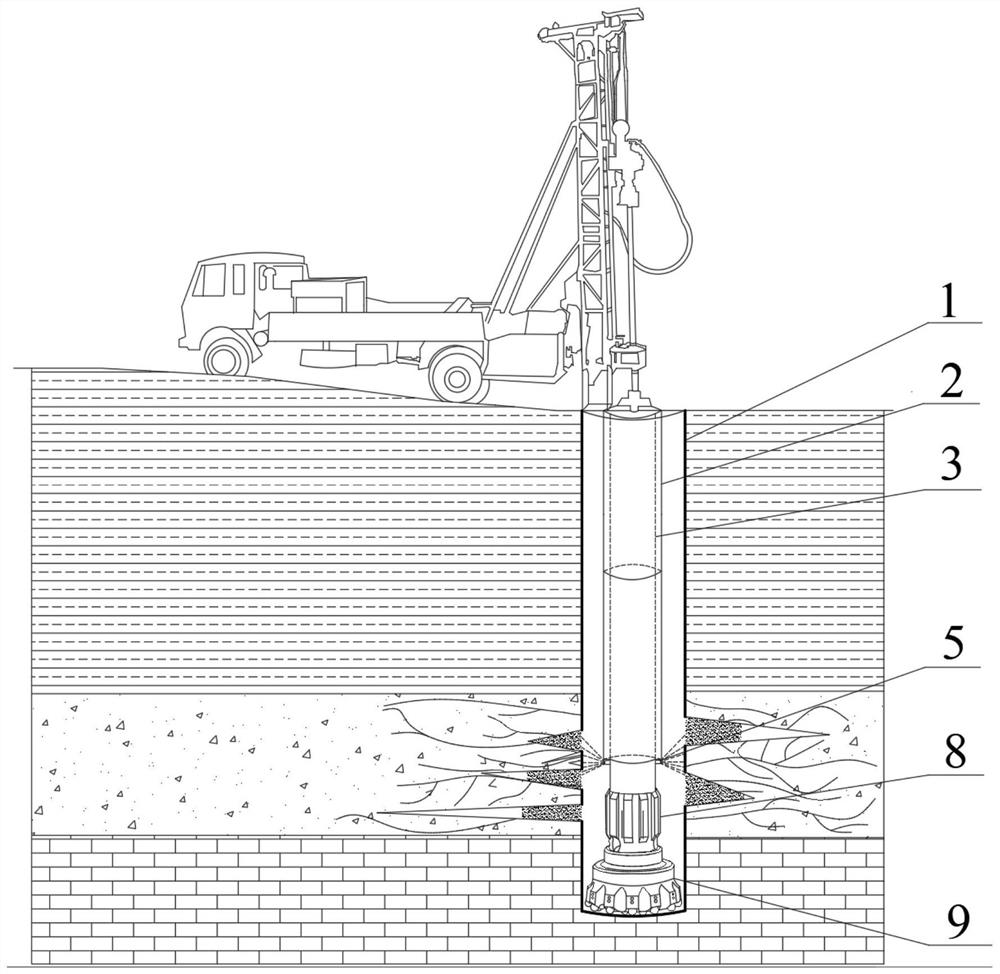

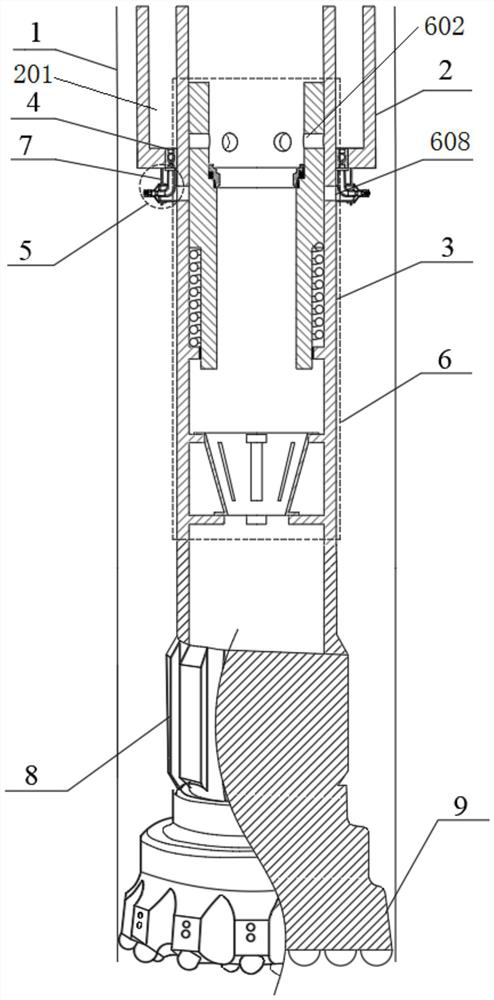

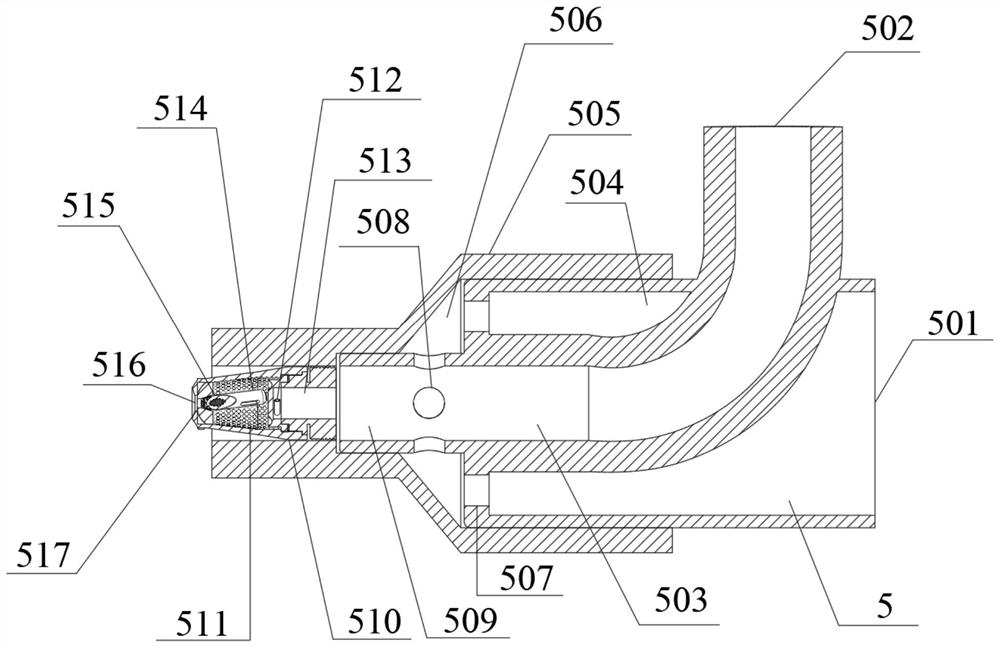

[0050] Such as Figure 1-Figure 7 As shown, this embodiment provides an emergency rescue drilling while drilling water plugging device, including a bypass assembly 6, a pneumatic nozzle 5 and a drill pipe with an inner cavity, wherein: see figure 1 As shown, the drill pipe is stretched into the well, and the drill pipe is connected with the air down-the-hole hammer 8, and the lower end of the air down-the-hole hammer 8 is connected with a drill bit 9. At least the upper part of the drill pipe is a double-walled drill pipe with an inner tube 3 and an outer tube 2, see figure 1 , the upper part of the drill pipe in this embodiment is a double-walled drill pipe, and the lower part is an ordinary single-walled drill pipe; an accommodating chamber 201 for storing the leakage sealing agent is formed between the inner pipe 3 and the outer pipe 2; the pneumatic nozzle 5 has uniform The liquid inlet 502 and the air inlet 501 are connected, and the liquid inlet 502 is connected with th...

specific Embodiment approach

[0071] see figure 2 , Figure 5 and Figure 6 As shown, the bypass assembly 6 of this embodiment includes a lifting piston 605 and an elastic component, wherein: the lifting piston 605 is located in the inner cavity of the drill rod 604, the main flow channel 601 is formed in the lifting piston 605, and the bypass flow channel is arranged on the The bypass hole 602 on the peripheral wall of the lifting piston 605, the outer wall of the drill pipe 604 is provided with a communicating hole 608, and the communicating hole 608 communicates with the air inlet 501; the corresponding communicating hole 608 and the bypass hole 602 are located at the same On the vertical line, and the two are vertically staggered, and when the main channel 601 is blocked, the high-pressure airflow can push the lifting piston 605 to move downward and make the bypass hole 602 lead to the corresponding communication hole 608 Pass.

[0072] Such as Figure 5 and Figure 6 As shown, a plurality of bypas...

Embodiment 3

[0086] This embodiment is an improvement made on the basis of the above-mentioned embodiments. The drilling tool also includes a ball receiving mechanism 612. The ball receiving mechanism 612 is arranged in the inner cavity of the drill rod and is located below the bypass assembly 6 for receiving The valve opening ball and valve closing ball falling from the bypass assembly 6. The ball receiving mechanism 612 is located under the bypass assembly 6 and can receive the dropped valve opening and closing balls to ensure the smooth progress of the drilling work.

[0087] This embodiment provides a specific implementation of the ball receiving mechanism 612, see Figure 5 and Figure 7 As shown, the ball catching mechanism 612 of this embodiment includes a ball catching basket 619, which is used to receive the falling valve-opening balls and valve-closing balls; 620, the air can circulate through the grill hole 620;

[0088] The inner diameter of the ball receiving basket 619 dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com