Output torque management in a vehicle having an electric powertrain

A technology for outputting torque and vehicles, applied in hybrid vehicles, electric vehicles, motor vehicles, etc., can solve problems such as long shifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

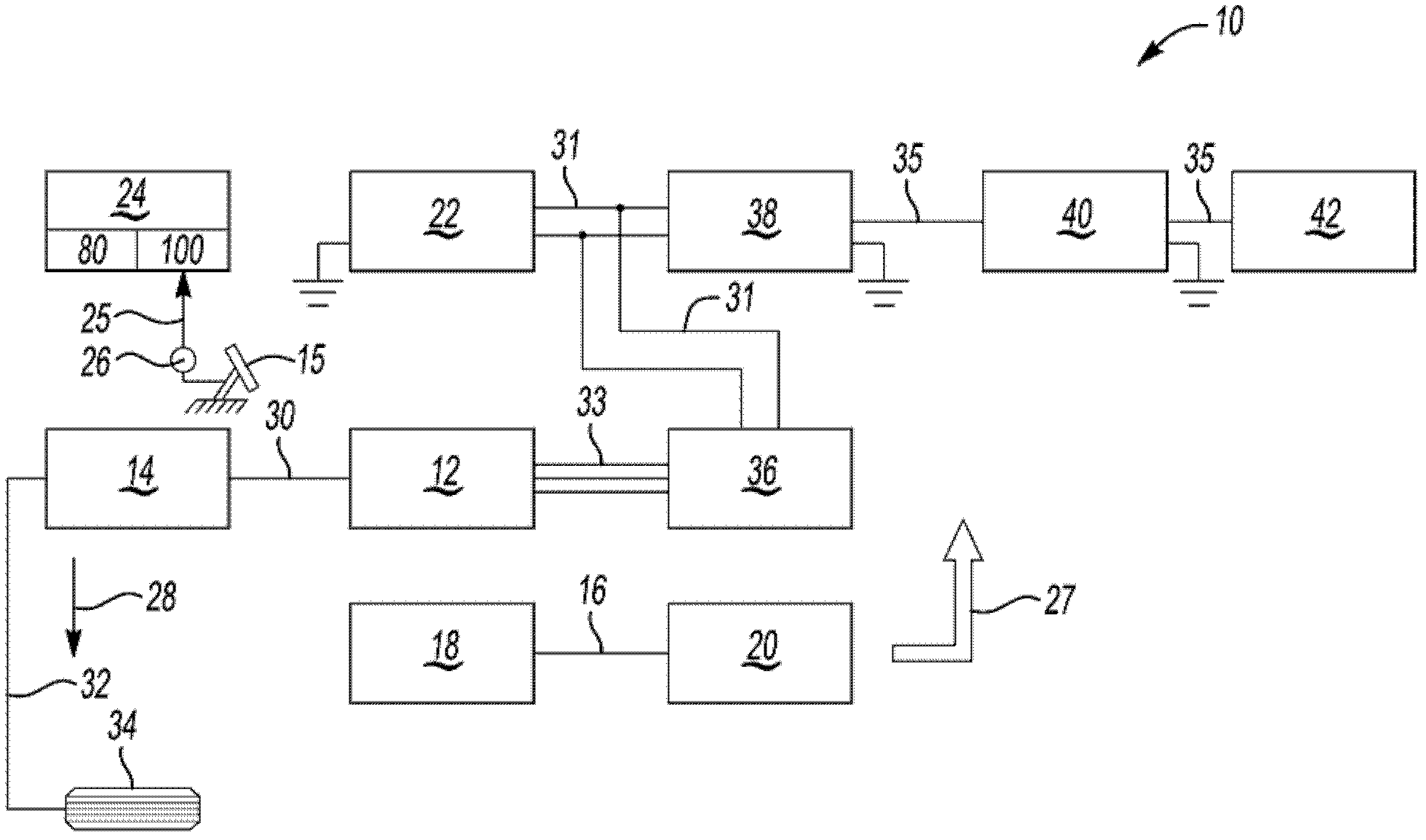

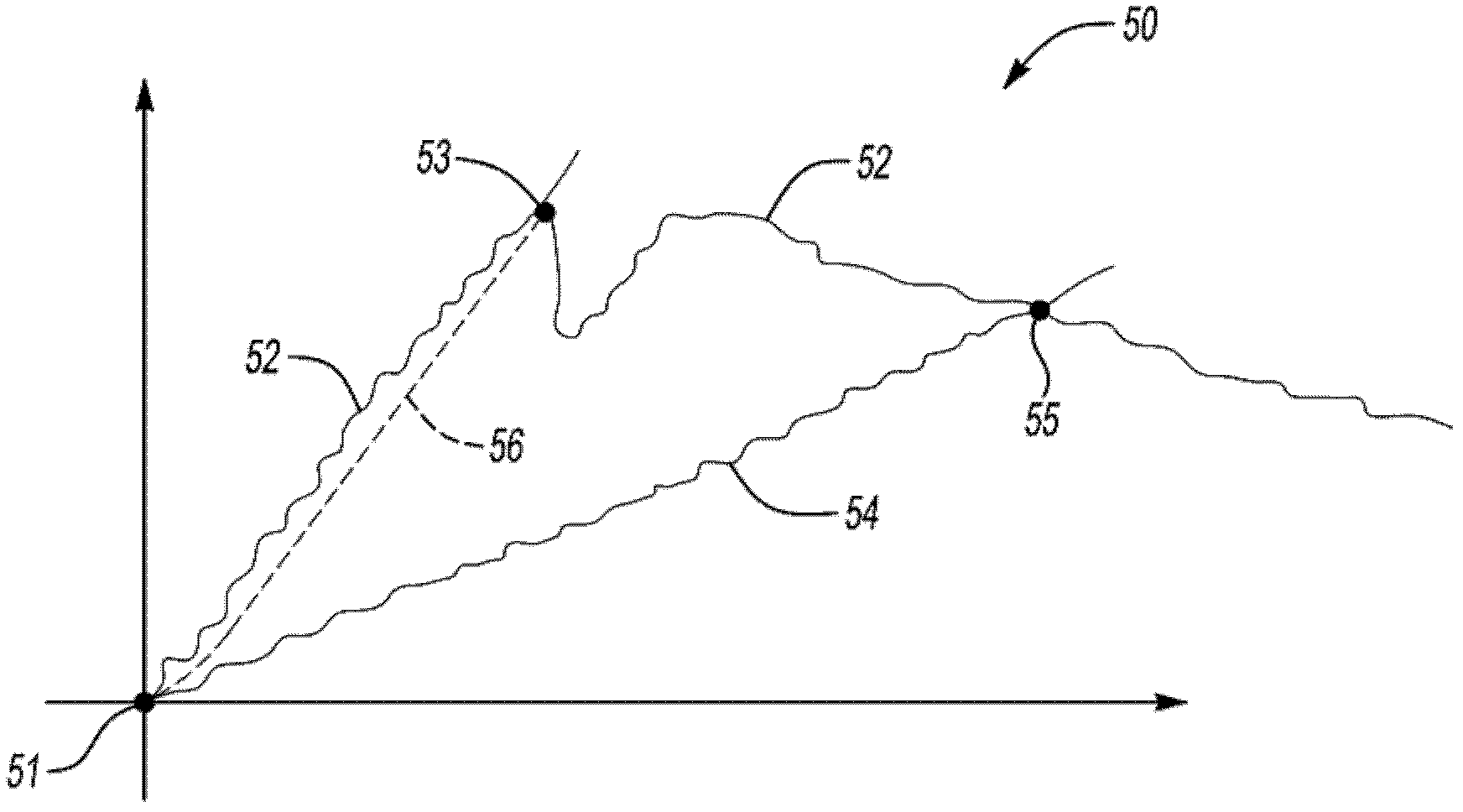

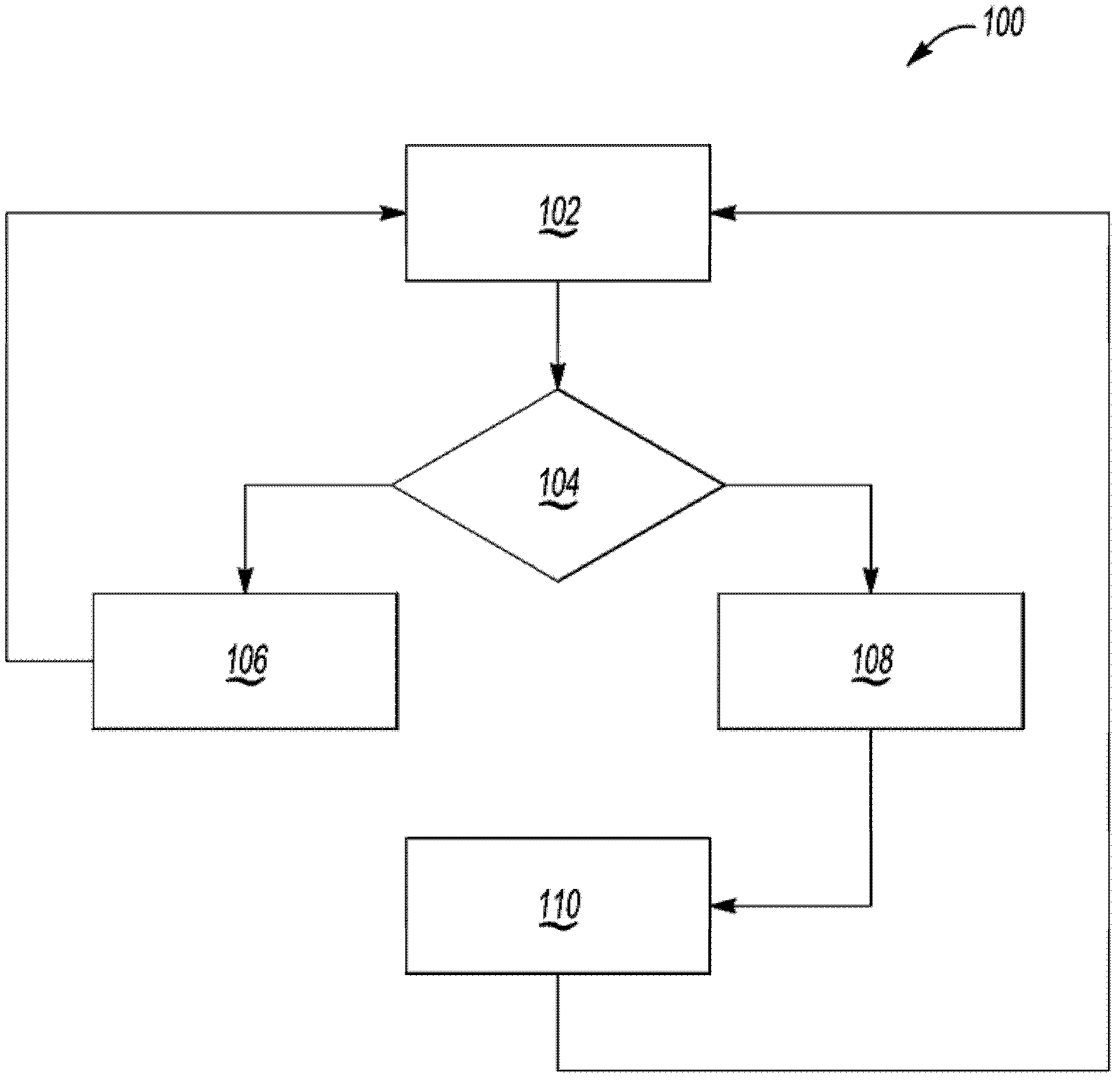

[0015] Referring to the drawings, a vehicle 10 is schematically shown at figure 1 middle. The vehicle 10 includes a controller 24 configured to perform a method 100, an embodiment of which is image 3 shown and described in detail below. Vehicle 10 is any vehicle having an electric vehicle (EV) powertrain, such as a battery electric vehicle (BEV), an extended-range electric vehicle (EREV), a hybrid electric vehicle (HEV), or any other vehicle capable of propulsion in EV mode, i.e., only A vehicle that is propelled using electric motor torque. The controller 24 automatically manages sudden increases in output torque capability on the vehicle 10 by controlling the rate of change of actual output torque when an increase in output torque capability is perceived.

[0016] The high voltage electric traction motor 12 outputs motor torque to a transmission 14 and thereby powers the vehicle 10 in EV propulsion mode. An internal combustion engine 18 may be included, which may be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com