Main shaft hoist shaft bottom coal pile monitoring system

A monitoring system and hoisting technology, which are used in elevators, hoisting equipment in mines, transportation and packaging, etc., can solve the problems of lifting the hoist tail rope, pulling the hoist tail rope, and hurting the hoist tail rope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

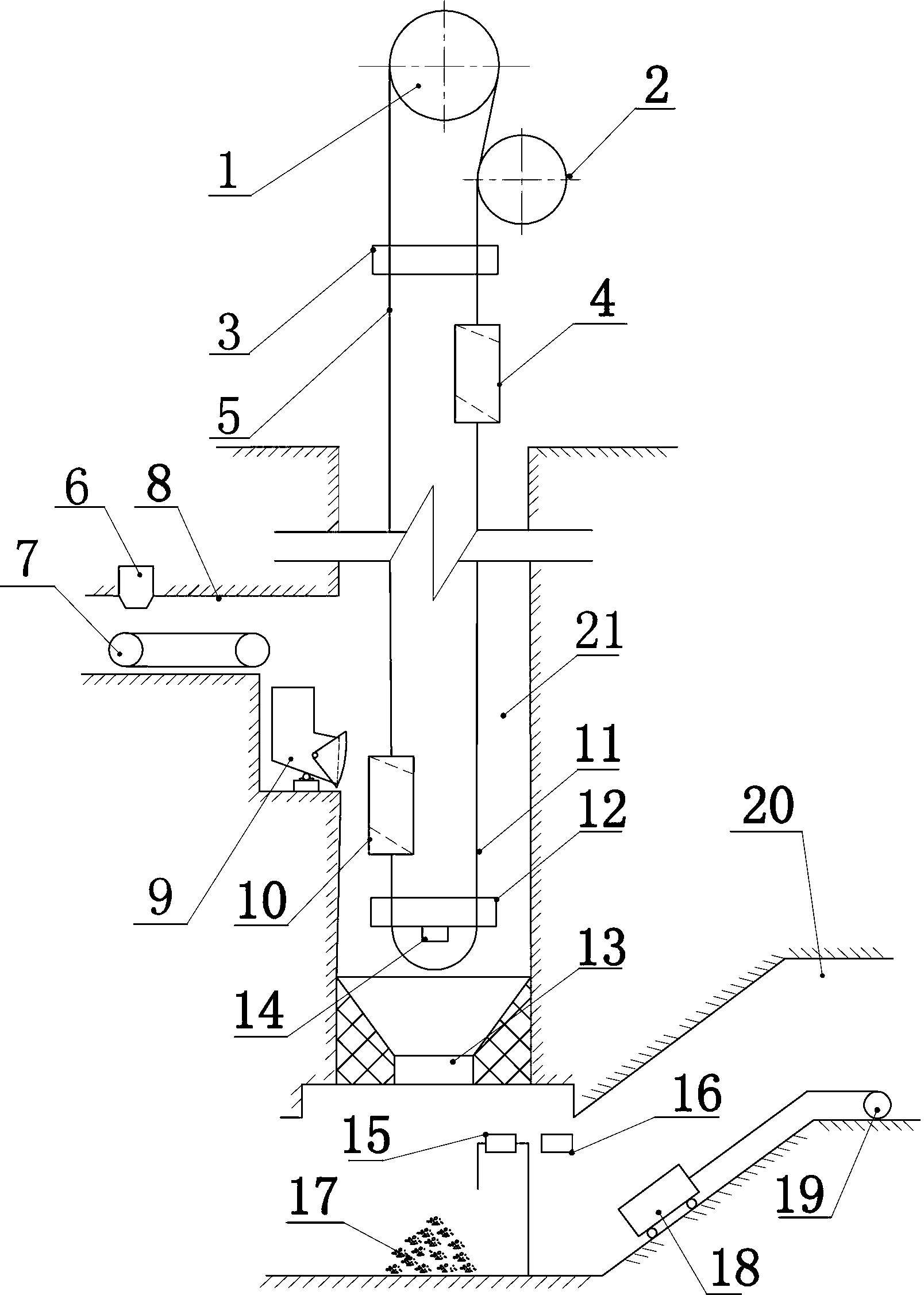

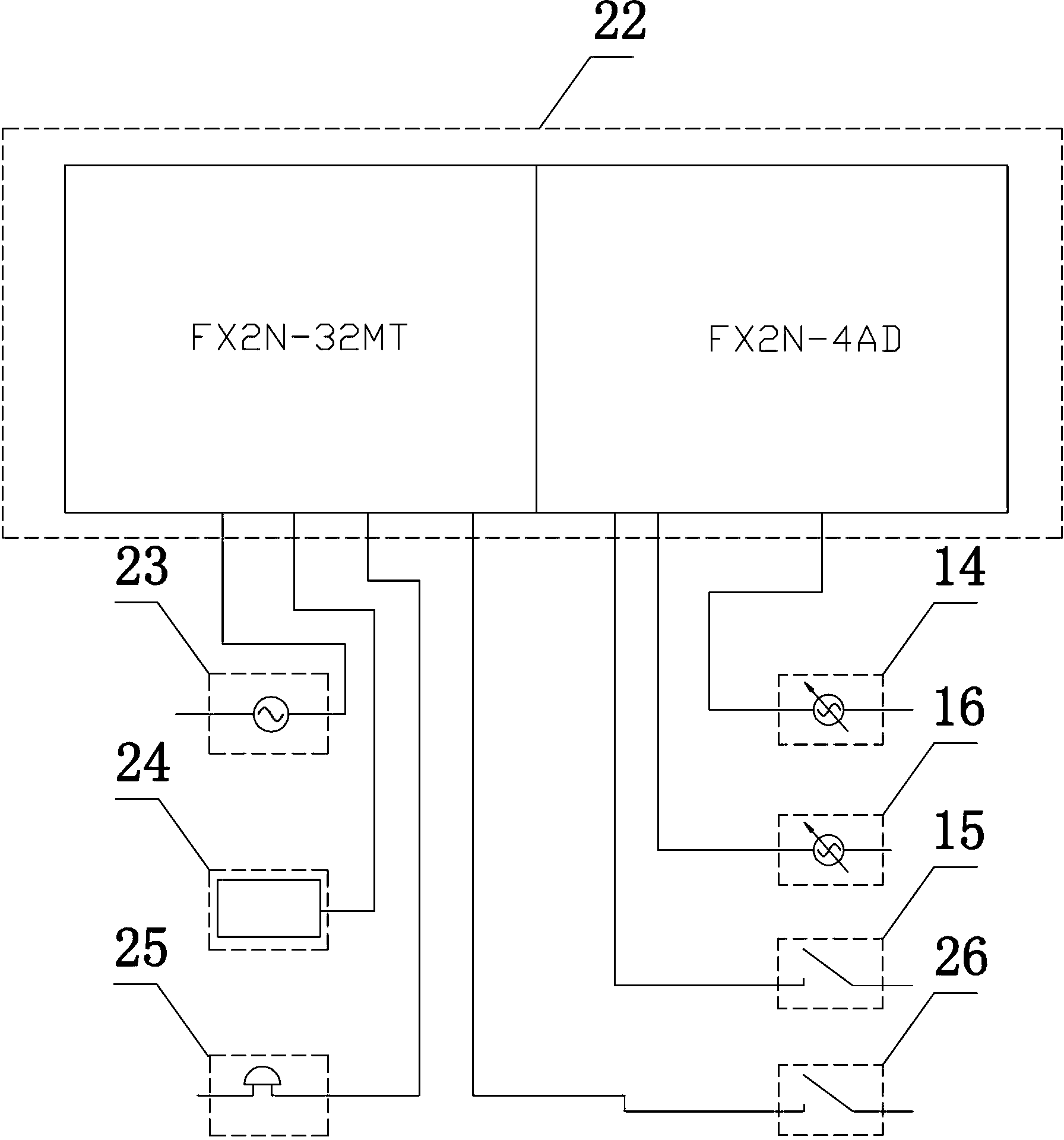

[0019] The structure diagram of the present invention is as figure 1 , 2 , 1, a kind of monitoring system of stacking coal at the bottom of the main shaft hoist, including coal stacking monitoring center 22, level instrument 14, coal level relay 15, wind speed sensor 16, power supply 23, F940GOT touch screen man-machine interface 24, driving alarm bell 25 . Drive control relay 26; characterized in that: coal pile monitoring center 22 is connected with the above components. According to the coal pile monitoring system at the bottom of the hoist in the main shaft, it is characterized in that: the coal pile monitoring center 22 is composed of a programmable controller and an analog input module, and receives a level meter 14, a coal level relay 15, and a wind speed sensor 16. data, to judge the coal pile situation at the bottom of the hoist in the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com