Guide needle assembly for a jacquard guide bar

A technology of jacquard bar and bar needle, applied in knitting, warp knitting, textile and papermaking, etc., can solve the problems of difficulty in achieving high precision, the holding plate cannot be placed on, and cannot be aligned with the holding plate, etc. Yarn, the effect of reliable alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

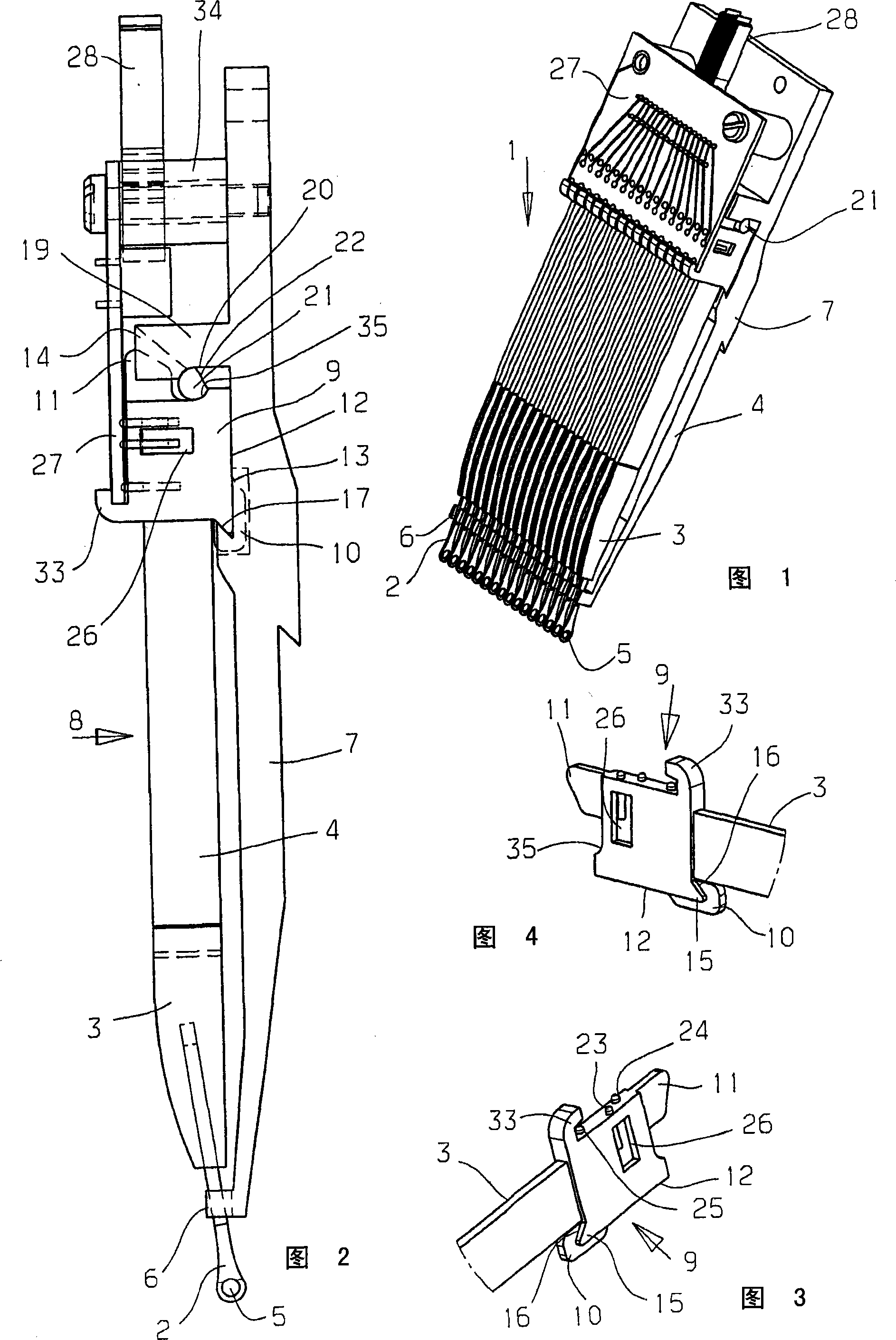

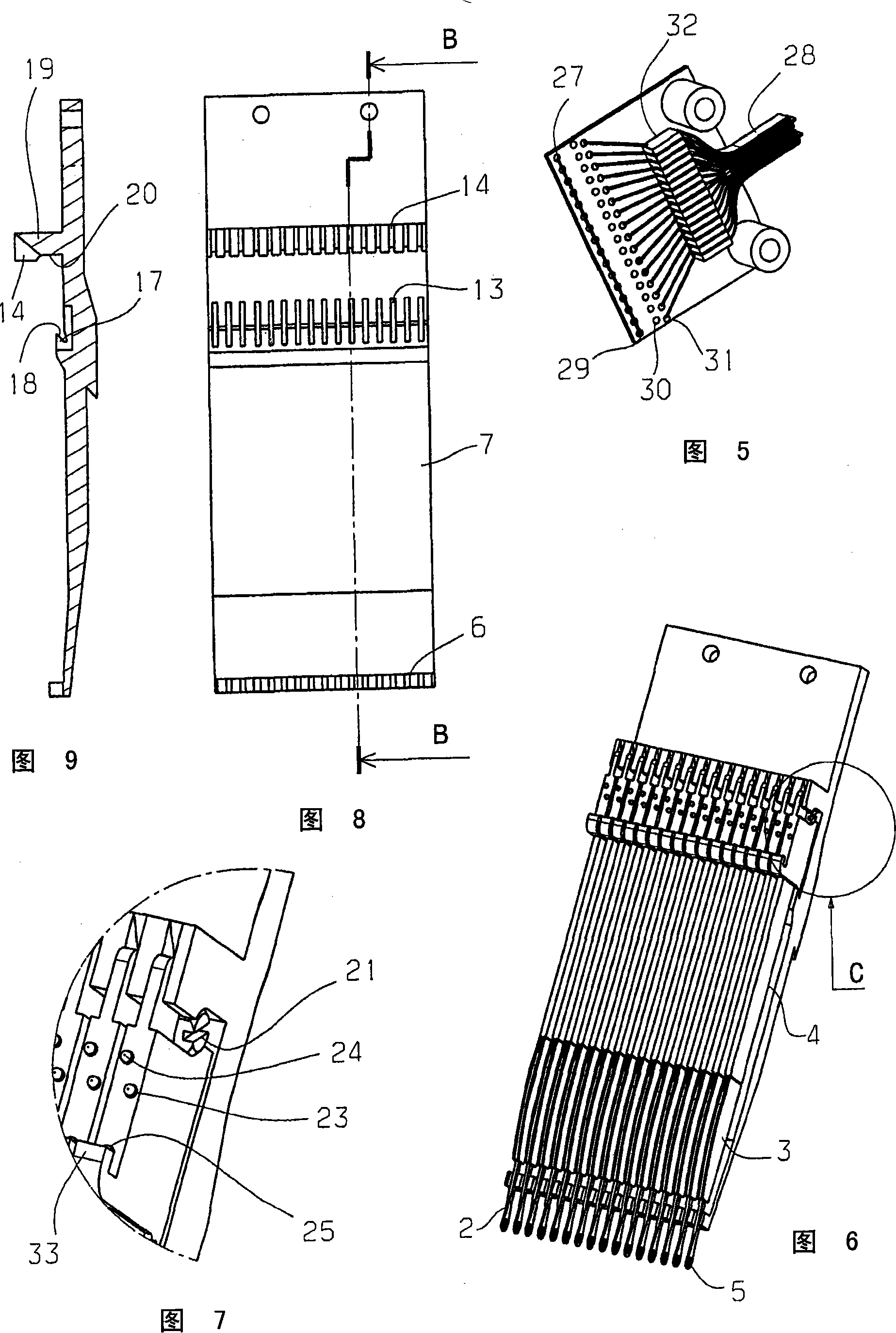

[0031] figure 1 A combing needle device 1 with a plurality of combing needles 2 is shown. The comb needles 2 are fixed on a comb needle holder 3 . Each bar needle holder is all equipped with at least one shifting transmission mechanism 4, here, only in figure 1 The outer displacement gear 4 of the outer bar holder 3 is shown in the middle. In many cases, however, the bar holder 3 is equipped with a shifting mechanism 4 on its two flat sides, so that in the shifting direction the bar bar 2 can be pivoted in both directions. The shifting direction refers to the direction in which the needle heads 5 of all comb needles 2 are arranged one behind the other. The movement of the comb needle 2 controlled by the displacement transmission mechanism 4 along the displacement direction is limited by the stopper 6 .

[0032] The stops 6 are all mounted on a bracket 7 .

[0033] The combing needles 2 are part of a combing needle unit 8 . In addition to having the combing needle 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com