Temperature and pressure dual acting explosion-proof device

An explosion-proof device, temperature and pressure technology, applied in the direction of valve devices, safety valves, engine components, etc., can solve the problems that unsafe factors cannot be eliminated, and achieve the effect of solving the change of medium performance, convenient use and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

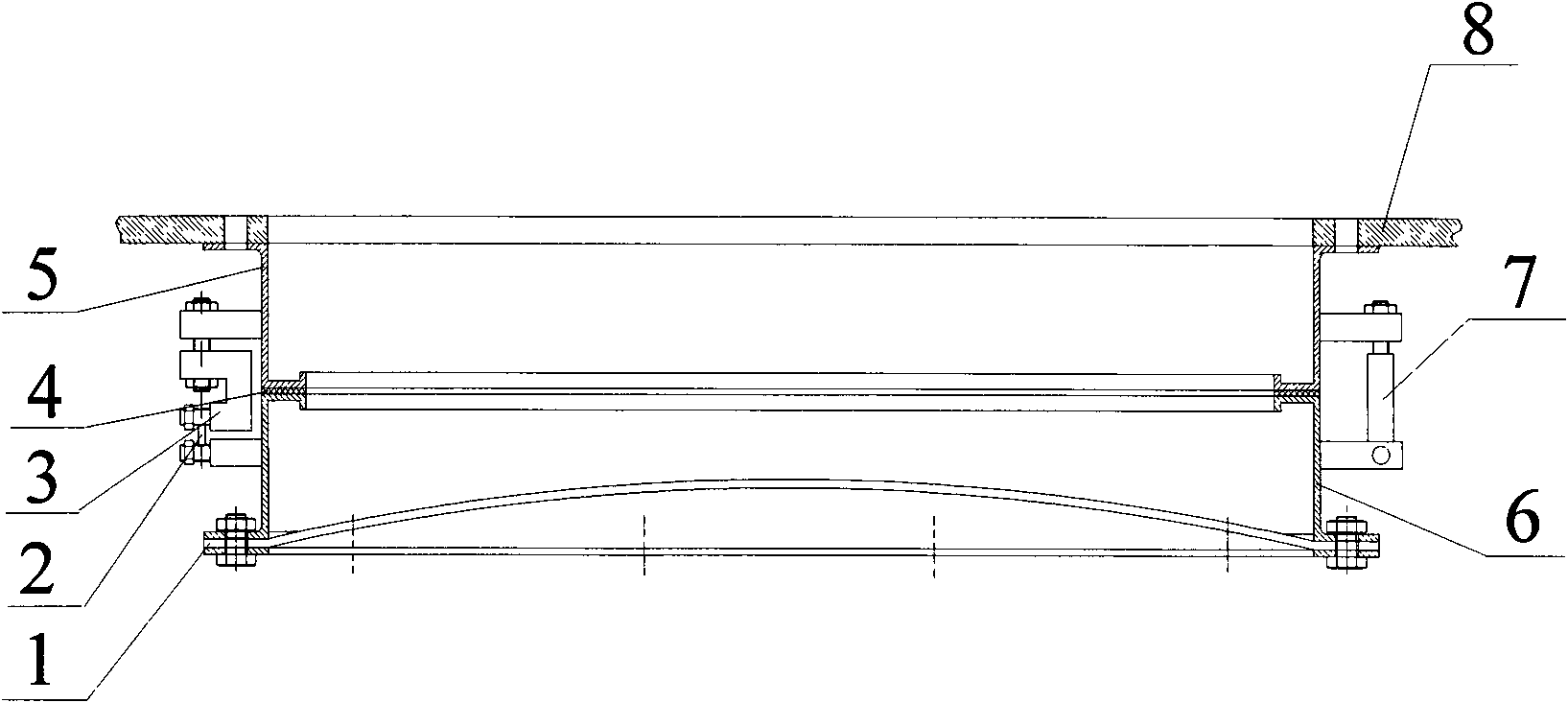

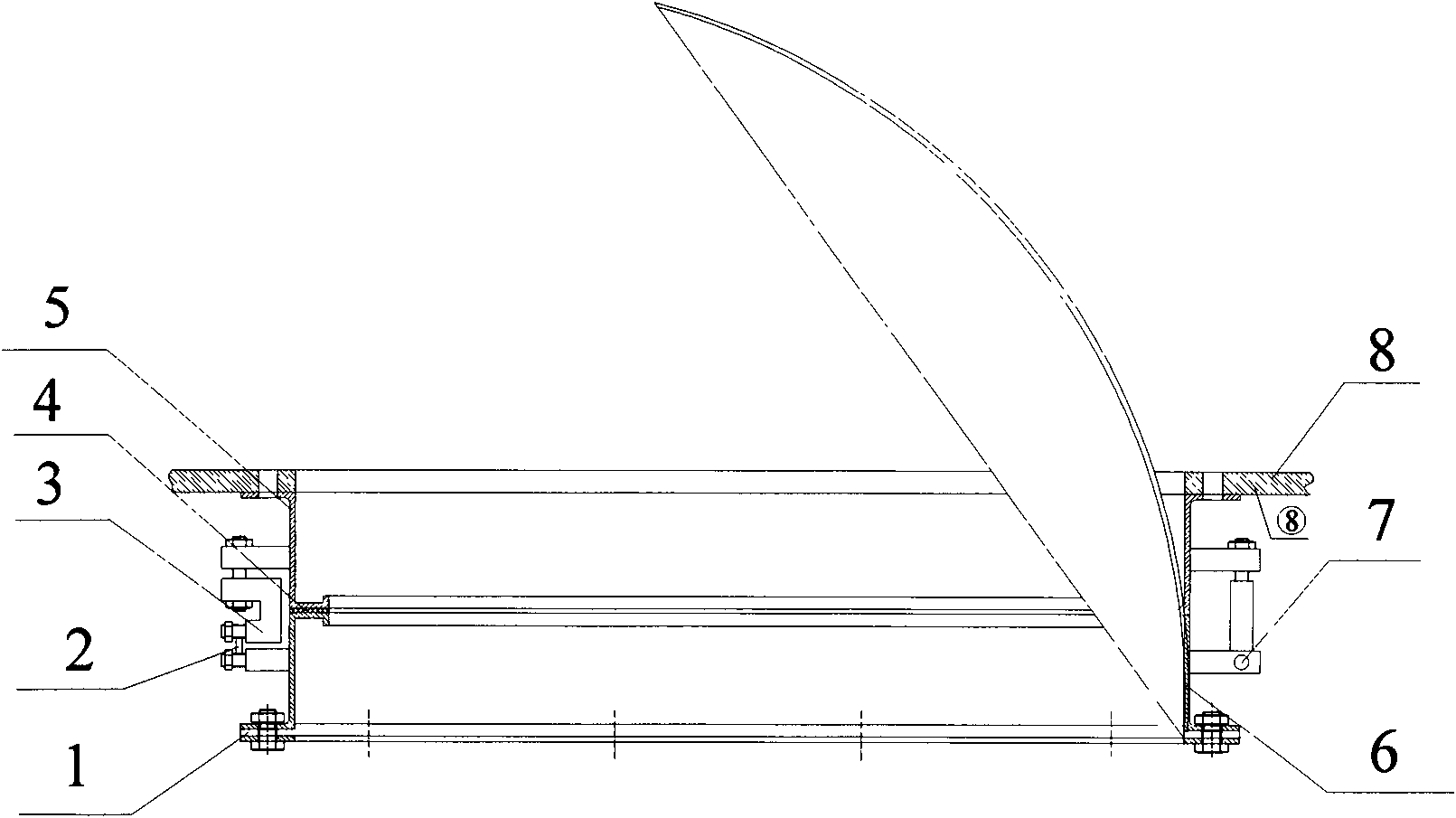

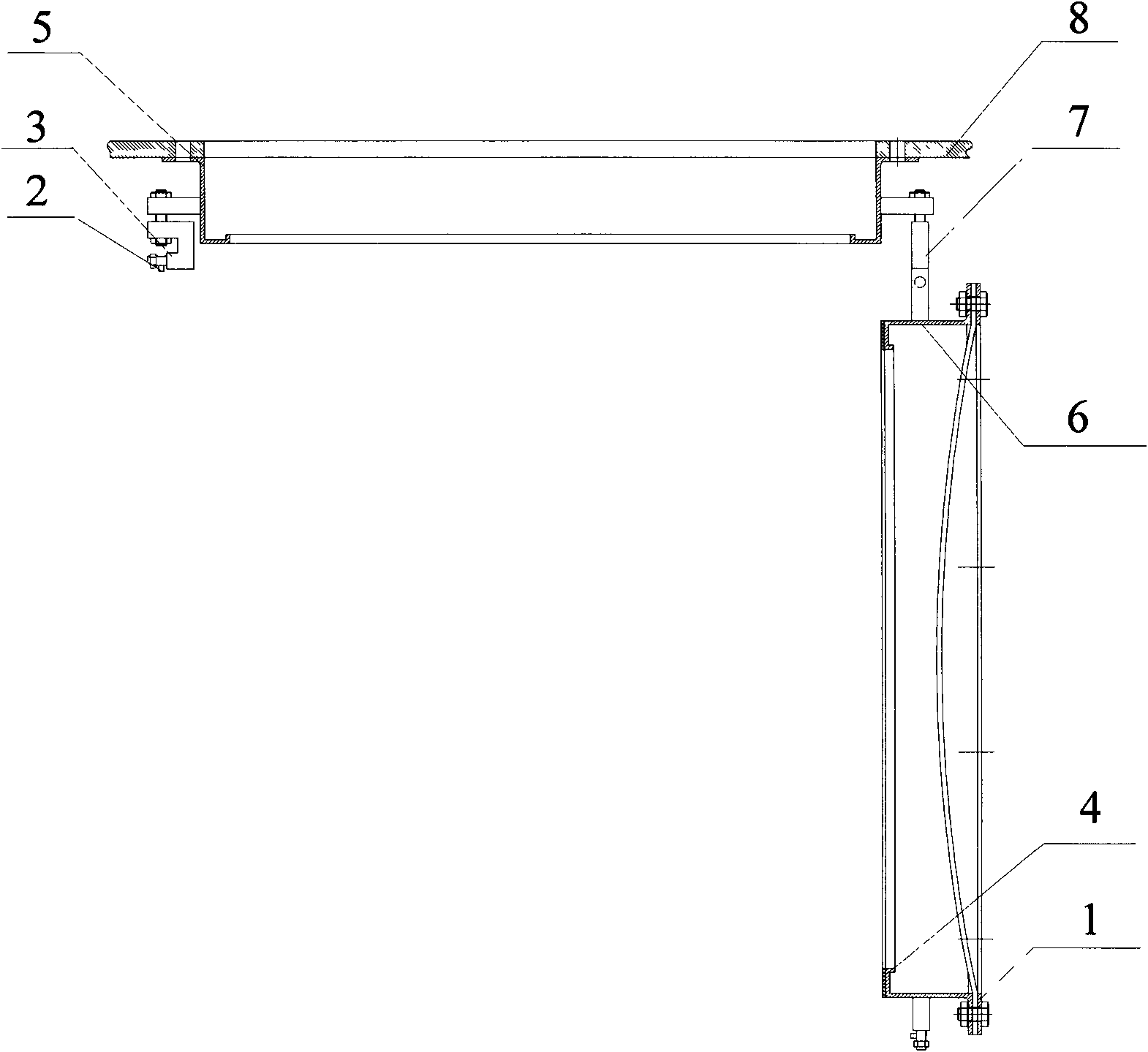

[0017] A temperature and pressure double-acting explosion-proof device, its structure is as follows figure 1 As shown, the device includes a bursting disc 1, a fuse pin 2, a connector 3, a sealing gasket 4, an adapter frame 5, a fixing frame 6 and a hinge 7. The device is installed in the equipment casing 8, and the adapter frame 5 is located The upper part of the fixed frame 6 is provided with a sealing gasket 4, which acts as a seal under the pre-tightening force of the fuse pin 2. The bursting disc 1 is arranged at the lower part of the fixed frame 6, and the bursting disc 1 is used to control the blasting at the set temperature. Pressure is the set pressure relief element. Different bursting disc structures can be selected according to different set relief pressures and relief diameters. Once the pressure in the equipment reaches the set burst pressure, bursting disc 1 will open and release pressure, the direction of pressure relief is vertically upward. The hinge 7 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com