Heavy oil gasifier burner

A gasifier and burner technology, which is applied in the field of heavy oil gasifier burners, can solve the problems of long purchase period, high burner price, inability to guarantee the timely supply of spare parts, etc., so as to achieve the effect of saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

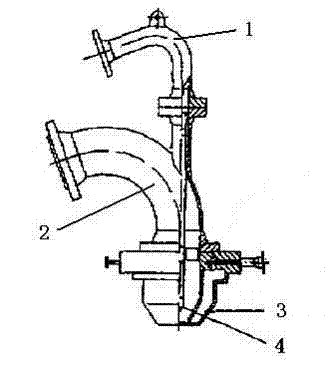

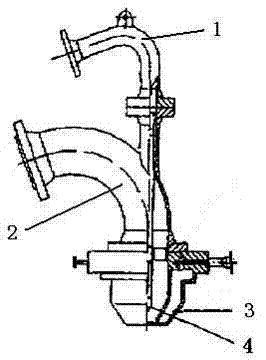

[0009] Such as figure 1 As shown, a heavy oil gasifier burner includes an oil elbow 1, an air elbow 2, and a nozzle 3. The oil elbow 1 and the gas elbow 2 are welded together, and the gas elbow 2 is installed There is a nozzle 3, and a spray gun 4 is connected with the oil elbow 1 and the air elbow 2.

[0010] The gas elbow 2 is the channel through which oxygen and steam enter the burner, and plays the role of positioning the spray gun 4; in order to ensure the long-term normal operation of the burner, the geometry and position of the flame injection in the furnace must be strictly controlled, requiring the nozzle 3 and The spray gun 4 should be strictly concentric; the spray gun 4 atomizes the heavy oil into atomized oil droplets, so that the reaction contact area between the oil and the gasification agent increases to obtain a better reaction effect; in order to form a closed flame for the spray gun 4, the oil The jet flow and the oxygen jet flow counter-rotate and eject at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com