Capacitive touch interface assembly

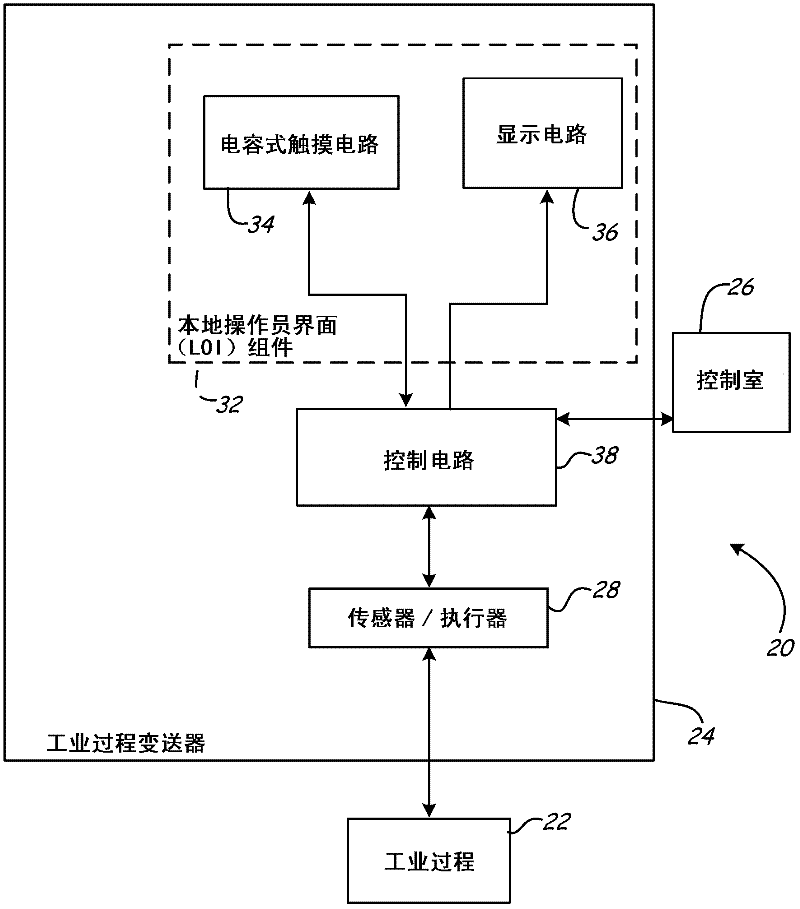

An interface component, capacitive technology, used in electrical components, electronic switches, electrical digital data processing, etc., which can solve problems such as difficult to remove covers and expensive programming equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

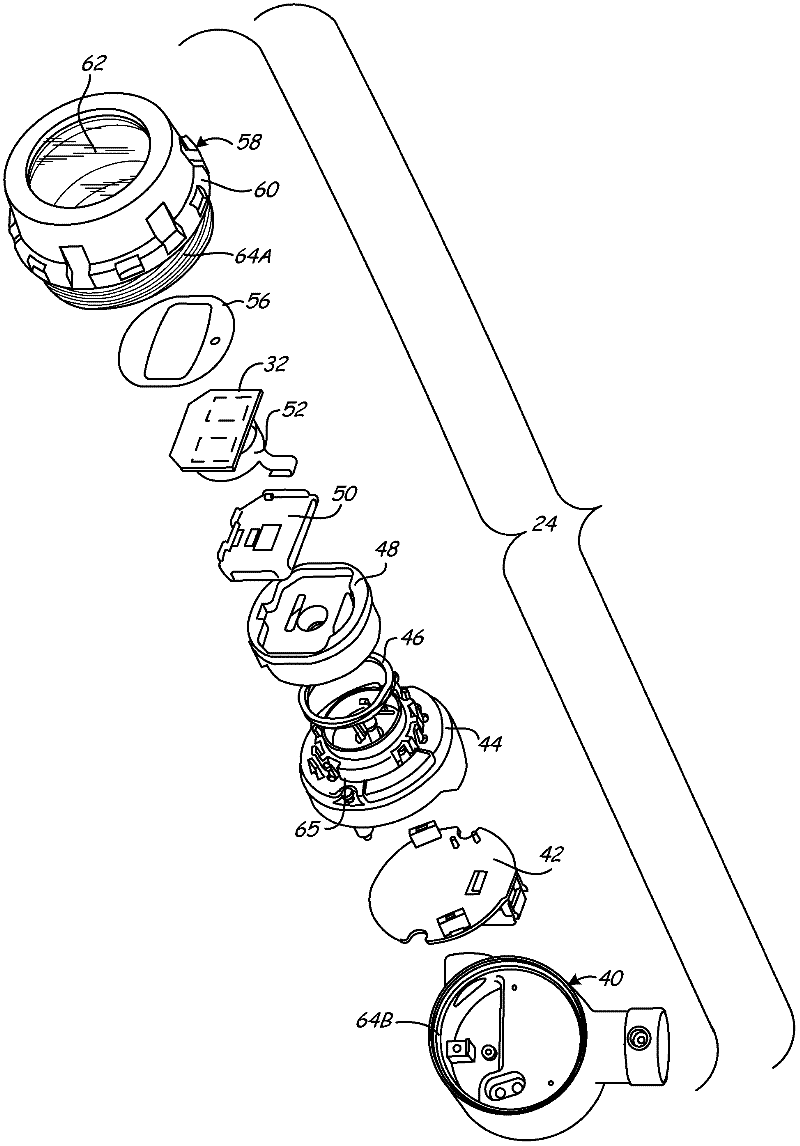

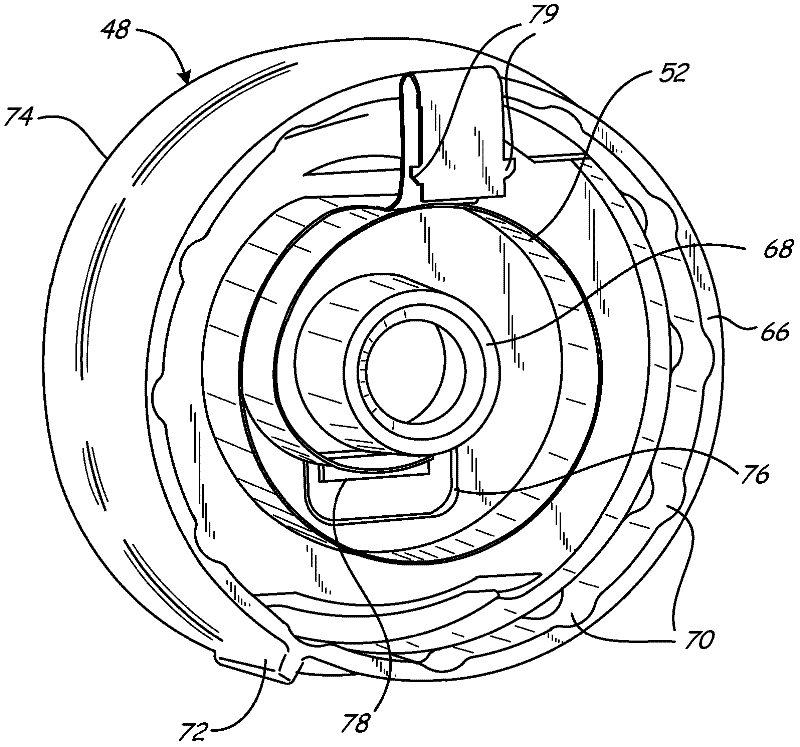

[0015] Industrial process transmitters are often used in environments that expose the transmitter to corrosion, fire, explosion, vibration, and other extreme conditions. For this reason, industrial process transmitters are specially constructed so that they can properly withstand the expected operating conditions. To this end, industrial process transmitters typically have rough housings with threadably attachable (ie, screw on) covers made of durable casting and machined metal materials. The cover can include a transparent portion positioned over the local interface assembly. In order to meet explosion-proof requirements, the transparent part is usually set as a relatively thick (for example, about 10 mm or more) piece of glass.

[0016] Ideally, an input is provided to an industrial process transmitter that can be actuated without removing the cover from the housing and exposing the interior of the industrial process transmitter to the environment. It is possible to sense ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap