Multi-bit convolution punching/tamping engineering groover

A multi-bit and slotting machine technology, applied in drilling equipment, earth-moving drilling, driving devices for rotary combined drilling, etc., can solve the problems of unsatisfactory efficiency, energy consumption and economy, and achieve good market prospects Crafty, high-stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

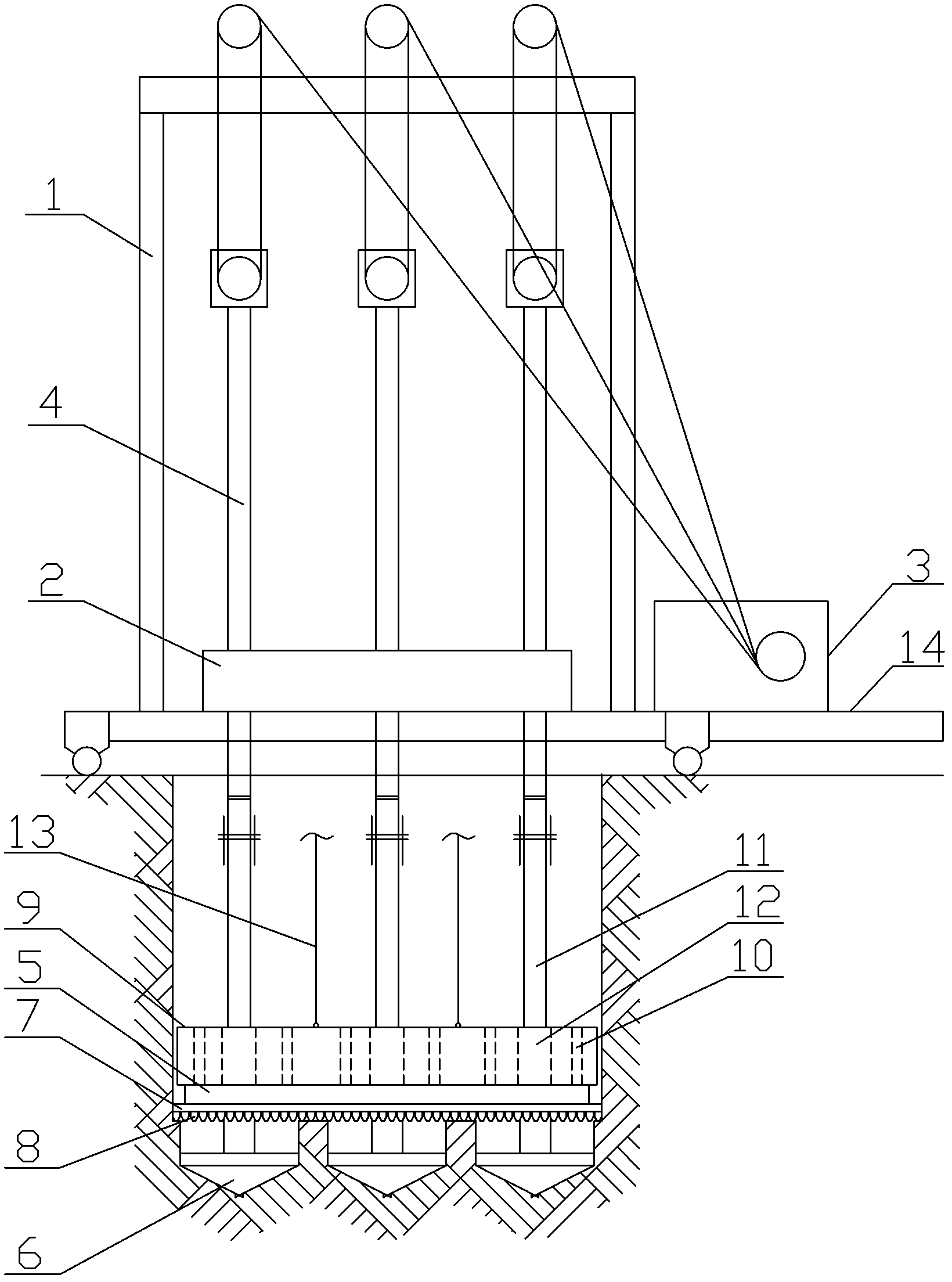

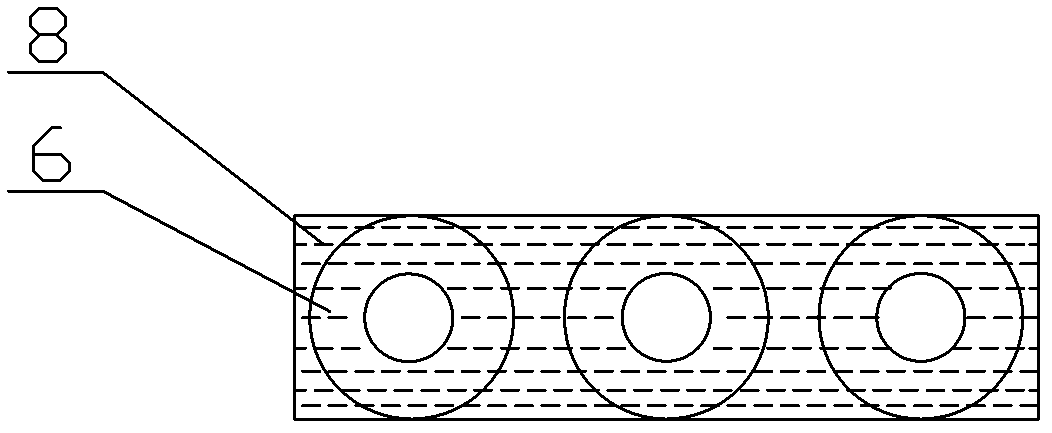

[0035] Such as figure 1 As shown, the multi-bit rotary punching engineering slotting machine of this embodiment consists of: frame 1, gearbox 2, hoisting equipment 3, control equipment (not shown in the figure), sewage device (not shown in the figure) , the gearbox 2 is fixed to the frame 1, and the slotting machine of this project also includes 3 stroke drill rods 4 symmetrically arranged, and a positioning beam 5, and the lower part of the positioning beam 5 is provided with 3 fixed beams fixed with the positioning beam in the vertical direction. The connected main drill bit 6 driven by the stroke drill rod can be used for gyrating motion. The lower end surface of the positioning beam 5 is fixed with a knife row seat 7, and the knife row seat 7 is provided with a knife row 8 with an alloy cutter head. There is a punching hammer 9 that can move up and down and can transmit the impact force to the positioning beam 5, the main drill bit 6 and the knife row 8.

[0036] Such as ...

Embodiment 2

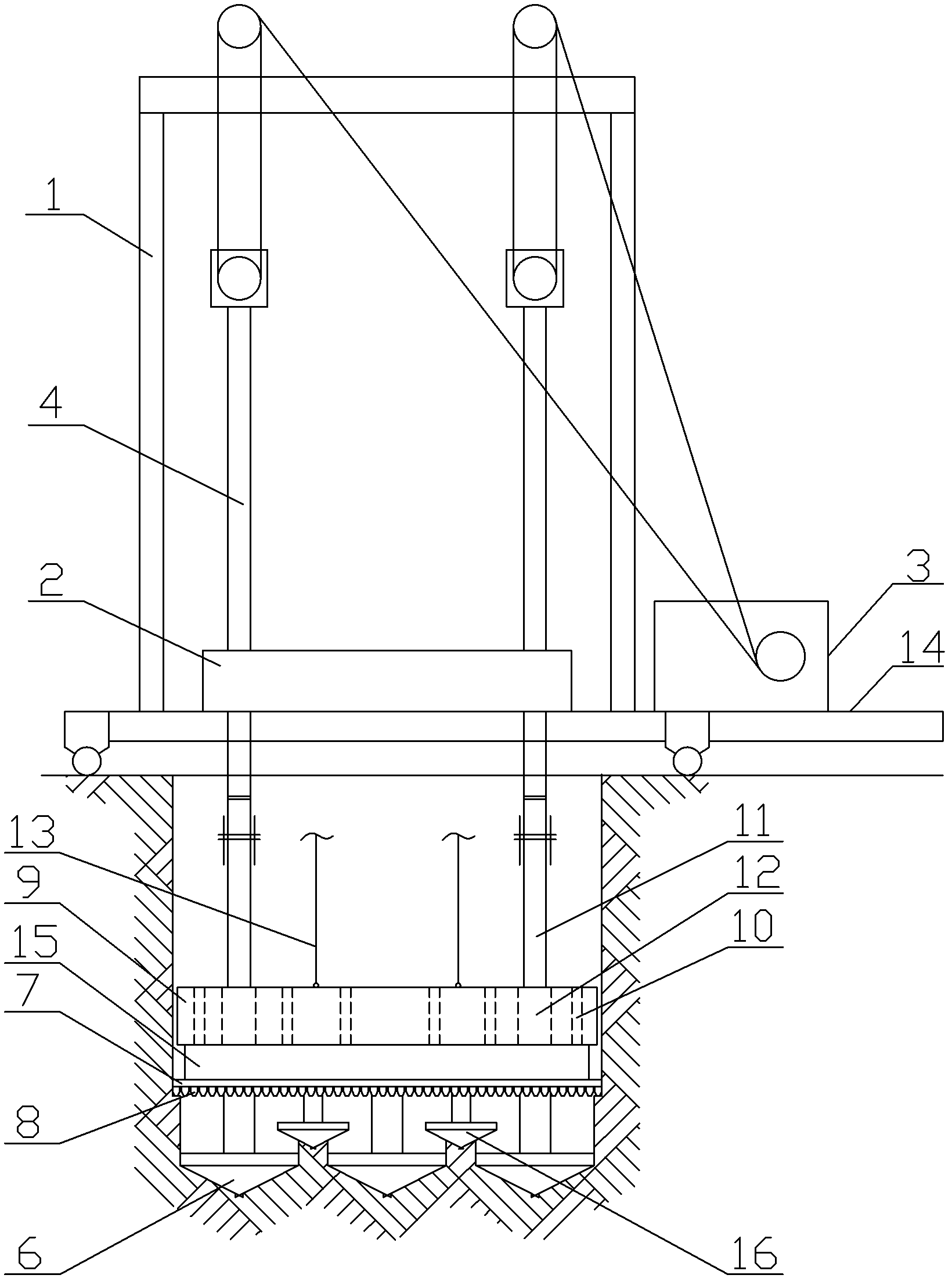

[0040] Such as image 3 As shown, the multi-bit rotary punching engineering slotting machine of this embodiment consists of: frame 1, gearbox 2, hoisting equipment 3, control equipment (not shown in the figure), and sewage device (not shown in the figure) , the gearbox 2 is fixed to the frame 1, and the slotting machine of this project also includes 22 stroke drill rods 4 symmetrically arranged, and a split head case 15 with a variable speed transmission mechanism (not shown in the figure), and the split head The lower part of the casing 15 is provided with some main drill bits 6 and auxiliary drill bits 16 that are fixedly connected with the transfer head casing 15 in the vertical direction, and the main drill bits 6 and auxiliary drill bits 16 are distributed in a cross-symmetric manner successively. 1. The auxiliary drill bit 16 is linked by the speed change transmission mechanism inside the transfer head case 15, the stroke drill rod 4 is connected with the drill rod 11 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com