Powder control structure of novel printer

A printer and powder control technology, which is applied in electrography, optics, instruments, etc., can solve the problems of light printing, blackness attenuation, bottom dust, etc., and achieve the effect of stable powder control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

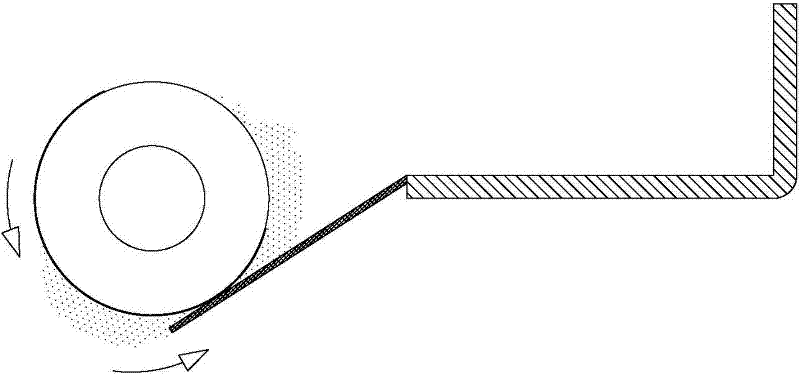

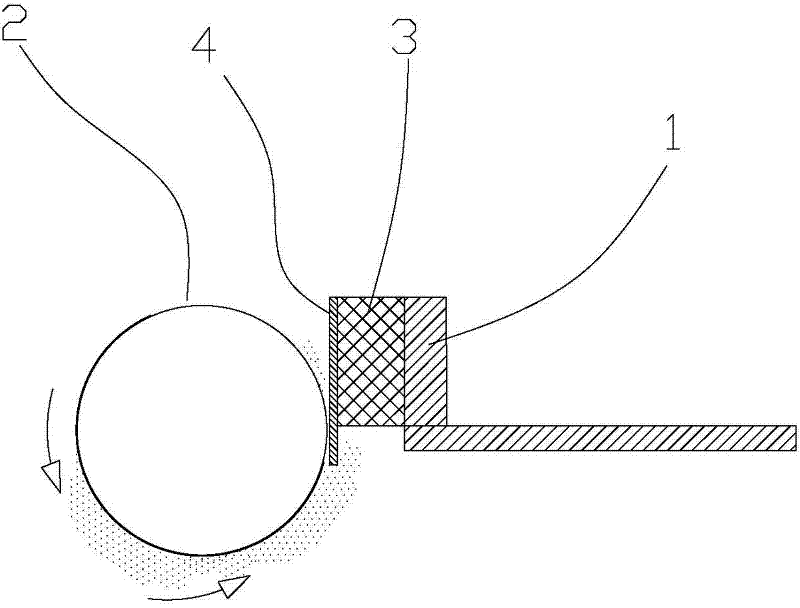

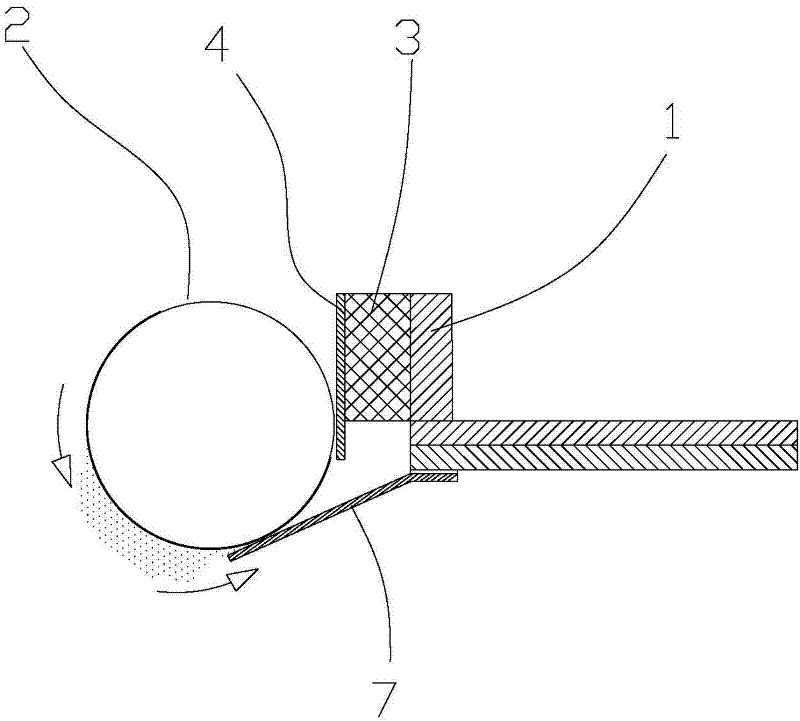

[0025] refer to figure 2 , the invention discloses a novel powder control structure for printers, which includes a supporting member 1 arranged in the toner cartridge and a metal friction member 4 in contact with the developing element 2, and an elastic Institution 3.

[0026] Such as figure 2 As shown, in this first specific embodiment, the metal friction member 4 is a metal sheet, and the elastic mechanism 3 is a rubber layer. Through the extrusion of the rubber layer, the charged carbon powder can form a uniform layer on the surface of the aluminum tube. layer, so that the powder control is stable, and the elasticity of the rubber layer can keep the friction between the metal sheet and the carbon powder within an appropriate range. In order to achieve convenient installation, the metal sheet is combined with the rubber layer by pasting, but the above-mentioned installation method does not constitute a limitation to the present invention. The above-mentioned structure ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com