Flexible limit support device for large-caliber light reflecting mirror

A light-weight mirror, limit support technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of thermal-structural deformation, local deformation cannot be eliminated, etc., to improve the ability to resist external load deformation , The effect of reducing the maximum principal stress and uniform force on the supporting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further explained:

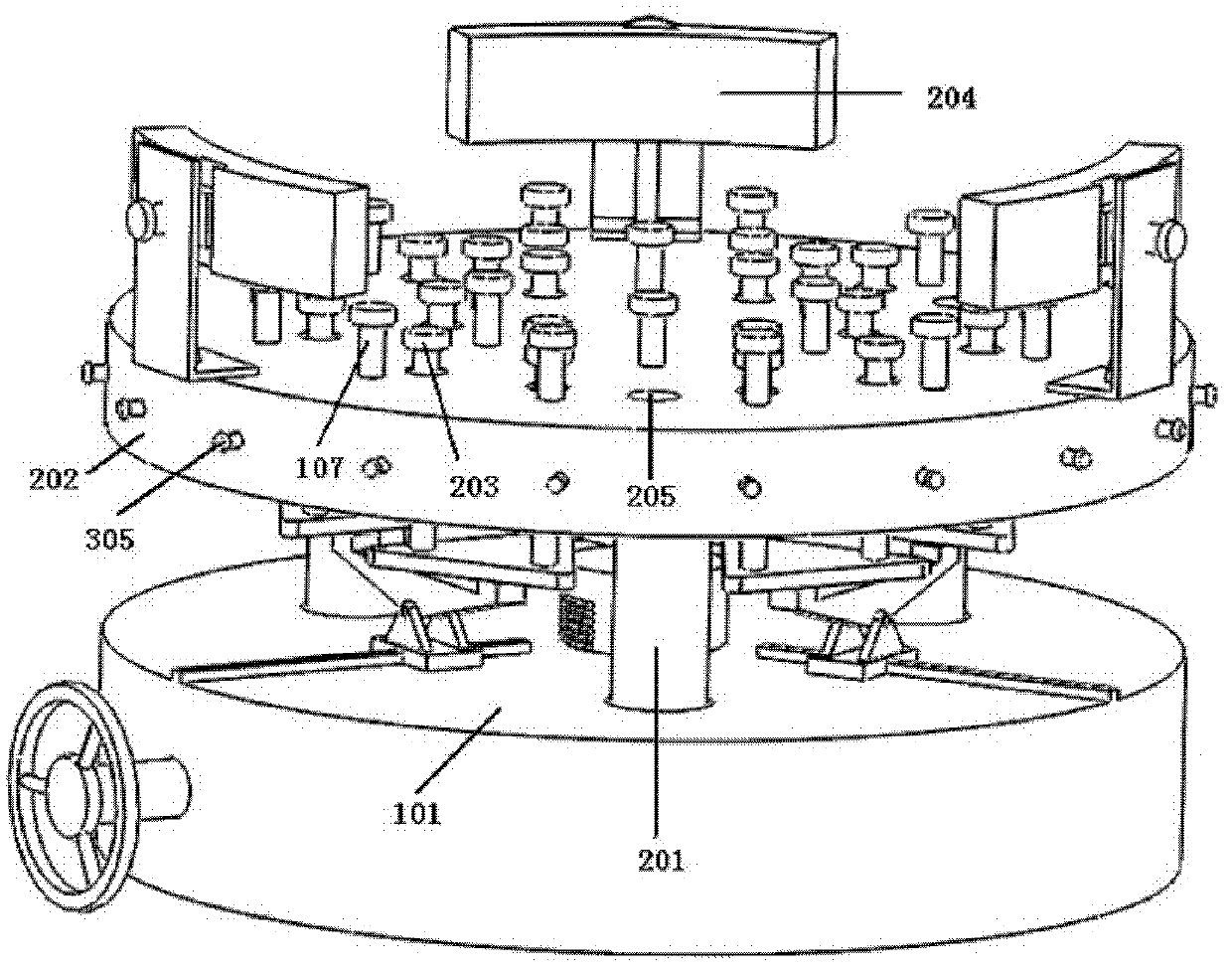

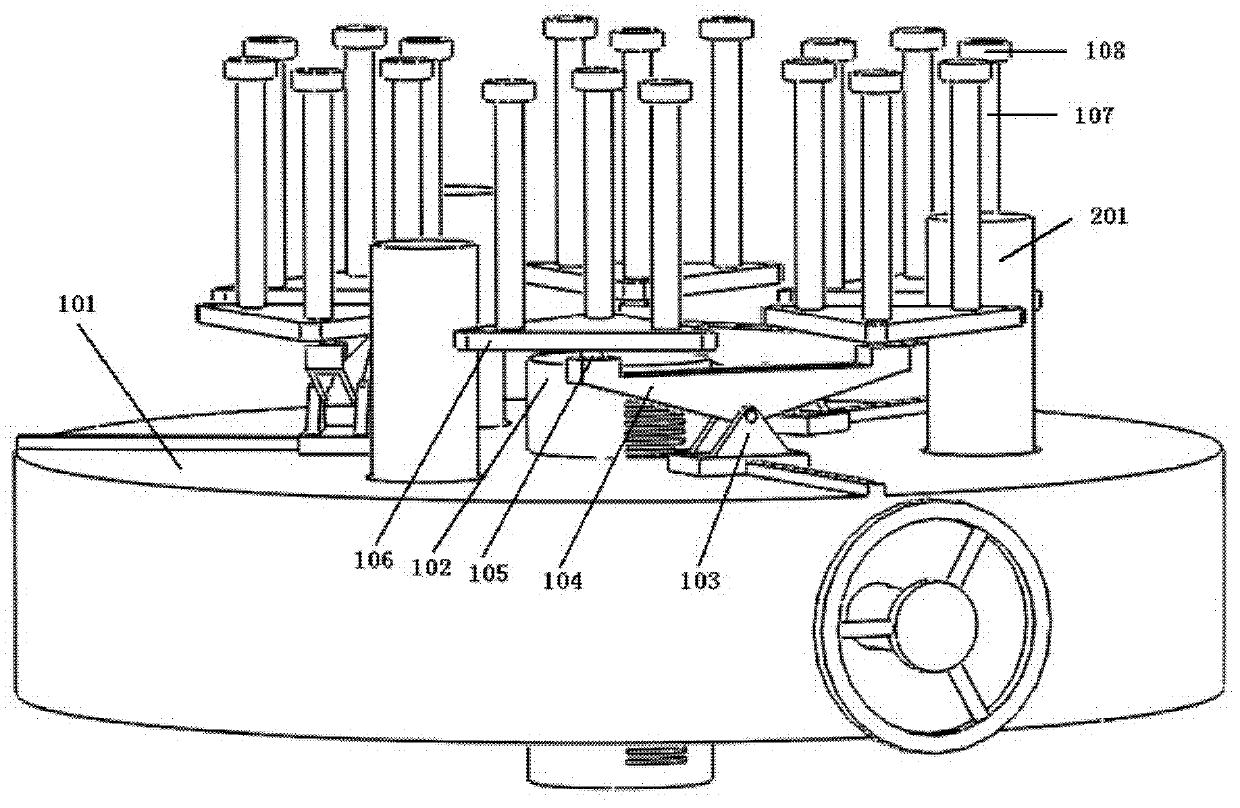

[0047] like figure 1 , 2 , 3, the floating support structure of the device of the present invention adopts the Whiffletree model, which is a transitional support structure model, and its purpose is to initially position the workpiece. The floating support structure mainly includes a base 101, a central column 102, a lever support frame 103, a lever 104, a ball 105, a tripod 106, a floating positioning column 107, a floating support plate 108, and a cylindrical pin 109. Wherein lever support frame 103, lever 104, ball 105, tripod 106 constitute floating lever balance model;

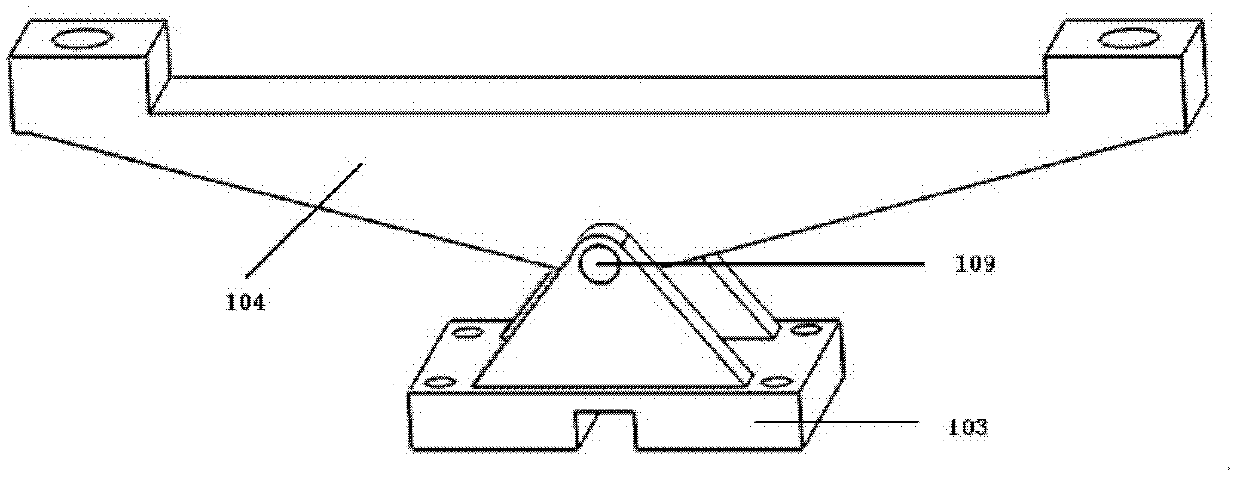

[0048] like image 3 As shown, the surfaces at both ends of the lever 104 are hemispherical concave surfaces, and the connection mode with the tripod 106 is a ball joint connection;

[0049] like figure 1 , 4 As shown, the flexible support structure mainly includes a support co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com