Up and down multi-chip dislocation saw for cutting plates

A sheet and cutting technology, used in circular saws, sawing components, sawing equipment, etc., can solve the problem of low cutting efficiency, high requirements for the position of upper and lower cutting, and inconvenient adjustment of feed shaft rollers and discharge materials, etc. problem, to achieve the effect of convenient operation, convenient adjustment and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

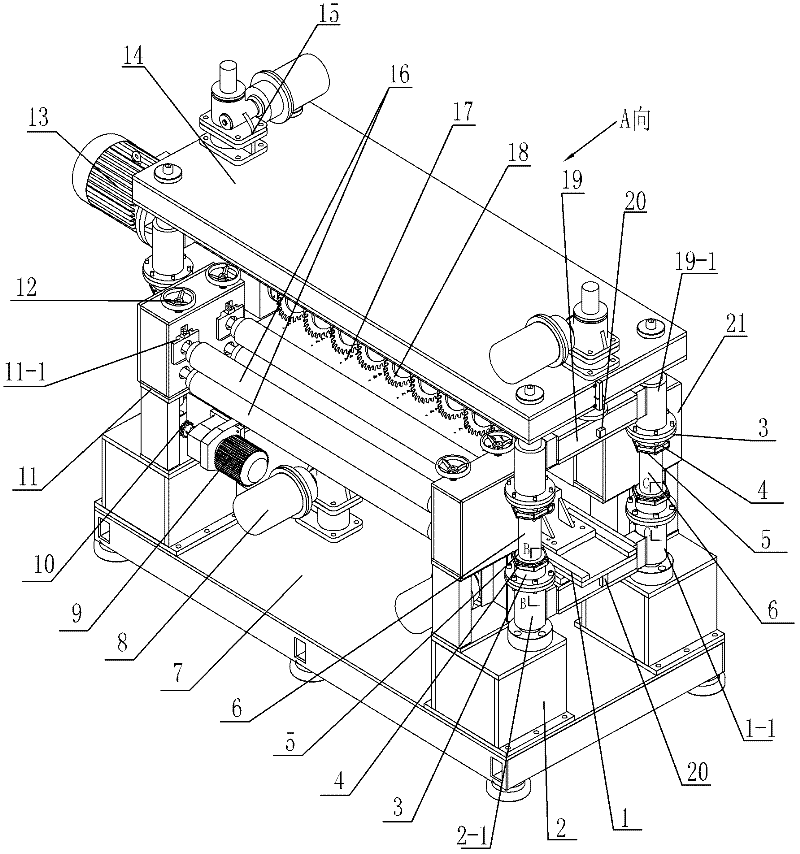

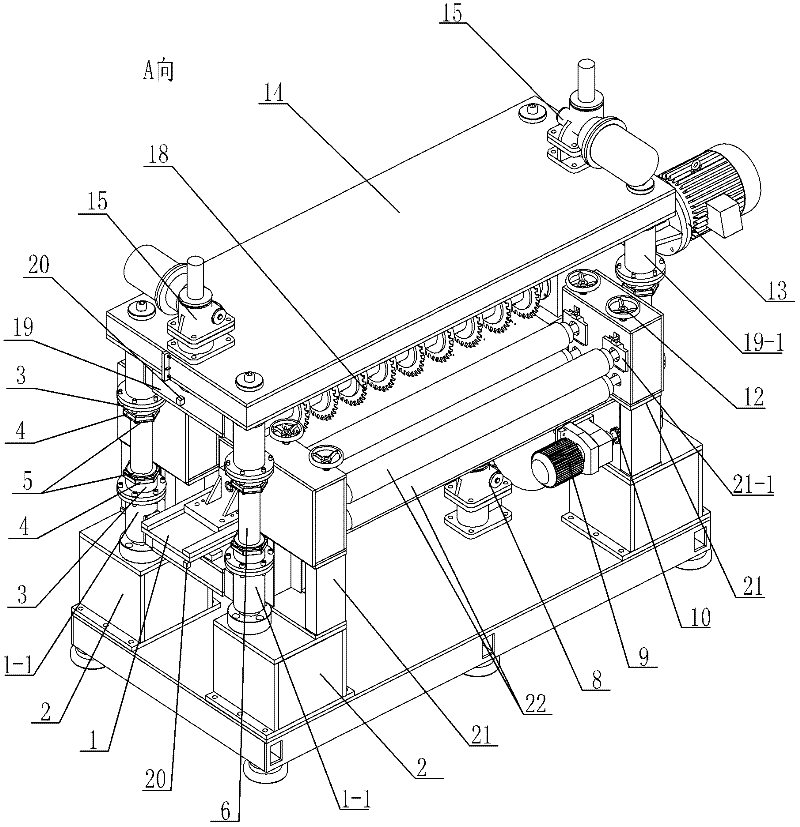

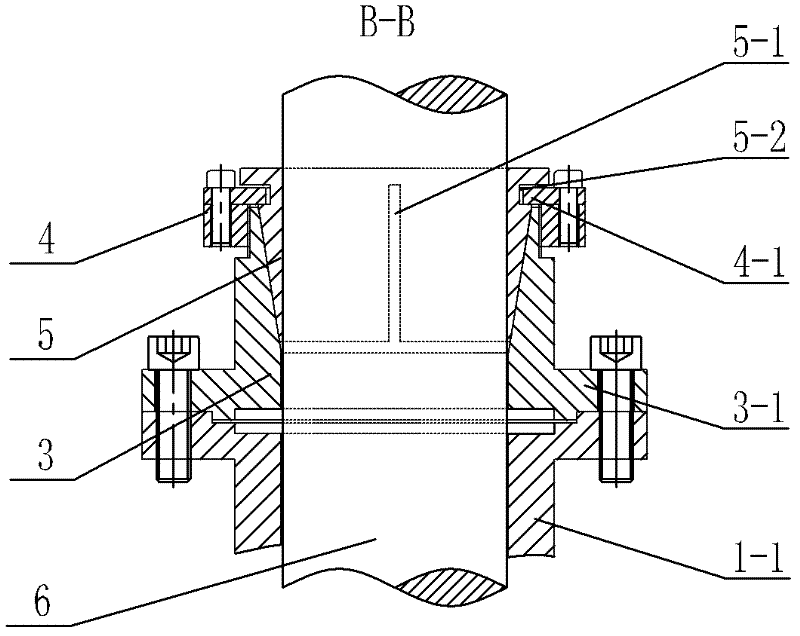

[0016] see figure 1 , 2 As shown, the present invention is used for cutting the upper and lower multi-displacement saws for cutting plates, including a machine base and upper and lower cutter shafts installed on the machine base. The cutter shaft motor 13 installed on the machine seat is respectively connected to the upper cutter shaft. Connected to the lower cutter shaft, the cutter shaft motor 13 is installed on the machine base, and the output shaft of the cutter shaft motor 13 is connected to the upper cutter shaft and the lower cutter shaft through a gear transmission mechanism or a chain transmission mechanism, or the present invention is on the machine base Two spindle motors 13 are installed on the upper blade, and each spindle motor 13 is connected to the upper blade shaft and the lower blade shaft respectively. The upper blade shaft and the lower blade shaft are driven by the blade shaft motor 13 to drive the upper blade 18 and the lower blade 17 to rotate against the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com