Charcoal / charcoal composite material SiC / ZrB2-SiC / SiC coating and preparation method thereof

A carbon composite material and composite material technology are applied in the field of preparation of carbon/carbon composite material anti-oxidative ablation coatings, which can solve the problems of easy peeling or poor oxidation performance, poor coating bonding performance, uneven distribution, etc. Excellent oxidative ablation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

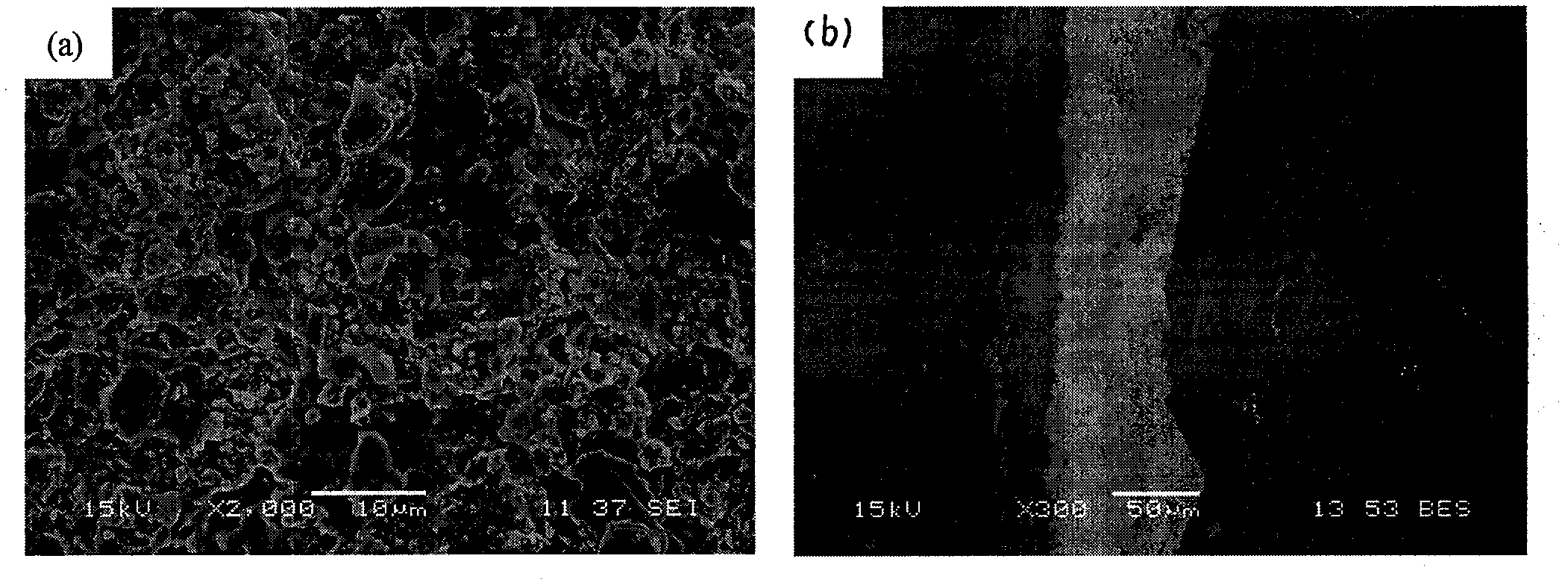

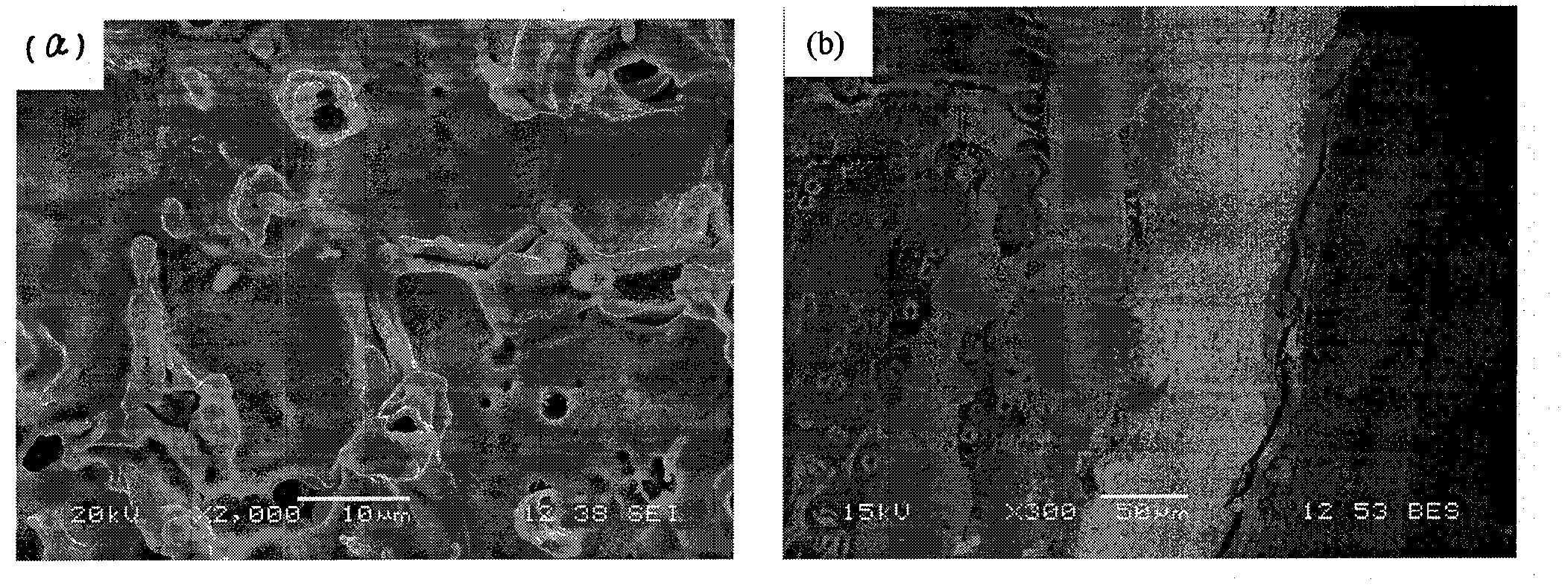

Image

Examples

Embodiment 1

[0034] This embodiment is a carbon / carbon composite material SiC / ZrB 2 - SiC / SiC coating, including an inner coating, an outer coating and an intermediate coating, wherein: the thickness of the inner coating is 20 μm, the thickness of the outer coating is 80 μm, and the thickness of the intermediate coating is 80 μm. The inner coating is SiC, and its composition includes 65wt% Si, 20wt% C and 15wt% Al 2 o 3 , the Si, C and Al 2 o 3 All are powder. Intermediate coating is ZrB 2 -SiC coating, and the ZrB 2 75wt% for SiC and 25wt% for SiC. The outer coating is CVD SiC coating.

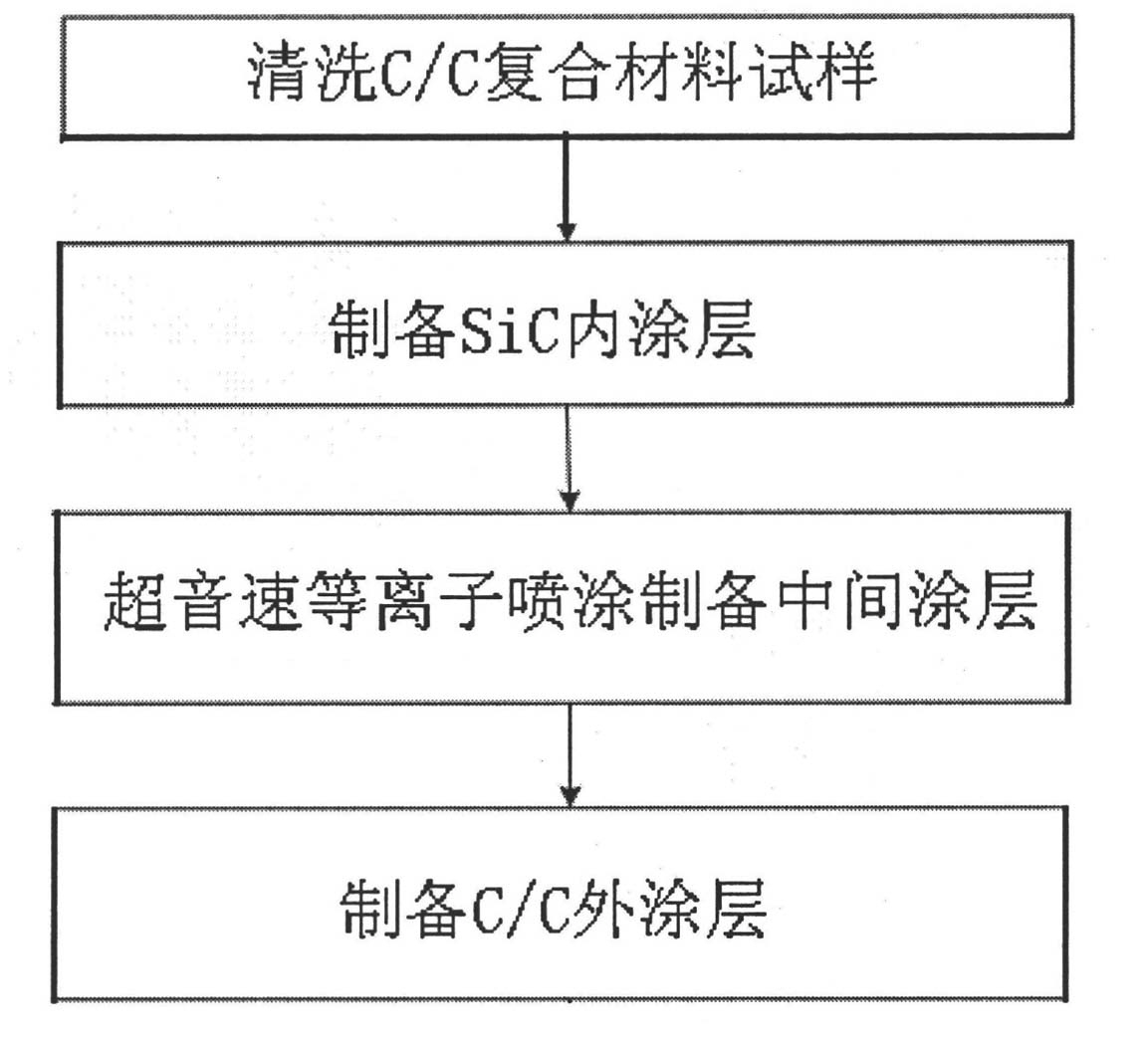

[0035] This embodiment also proposes a carbon / carbon composite material SiC / ZrB 2 -The preparation method of SiC / SiC coating, its specific process is:

[0036] Step 1, cleaning the C / C composite material sample. The polished C / C composite material was ultrasonically cleaned with absolute ethanol for 20 minutes, and then dried in an oven for later use; the drying temperature was 65°C; the ultraso...

Embodiment 2

[0047] This embodiment is a carbon / carbon composite material SiC / ZrB 2 - SiC / SiC coating, including an inner coating, an outer coating and an intermediate coating, wherein: the thickness of the inner coating is 30 μm, the thickness of the outer coating is 50 μm, and the thickness of the intermediate coating is 60 μm. The inner coating is SiC, and its composition includes 70wt% Si, 18wt% C and 12wt% Al 2 o 3 , the Si, C and Al 2 o 3 All are powder. Intermediate coating is ZrB 2 -SiC coating, and the ZrB 2 85wt% for SiC and 15wt% for SiC. The outer coating is CVD SiC coating.

[0048] This embodiment also proposes a carbon / carbon composite material SiC / ZrB 2 -The preparation method of SiC / SiC coating, its specific process is:

[0049] Step 1, cleaning the C / C composite material sample. Clean the polished C / C composite material ultrasonically with absolute ethanol for 25 minutes, and dry it in an oven for later use; the drying temperature is 75°C;

[0050] Step 2, prep...

Embodiment 3

[0060] This embodiment is a carbon / carbon composite material SiC / ZrB 2 - SiC / SiC coating, including an inner coating, an outer coating and an intermediate coating, wherein: the thickness of the inner coating is 50 μm, the thickness of the outer coating is 30 μm, and the thickness of the intermediate coating is 50 μm. The inner coating is SiC, and its composition includes 75wt% Si, 15wt% C and 10wt% Al 2 o 3 , the Si, C and Al 2 o 3 All are powder. Intermediate coating is ZrB 2 -SiC coating, and the ZrB 2 90wt% for SiC and 10wt% for SiC. The outer coating is CVD SiC coating.

[0061] This embodiment also proposes a carbon / carbon composite material SiC / ZrB 2 -The preparation method of SiC / SiC coating, its specific process is:

[0062] Step 1, cleaning the C / C composite material sample. Clean the polished and polished C / C composite material with anhydrous ethanol for 30 minutes, and put it in an oven to dry for later use; the drying temperature is 80°C;

[0063] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com