Special bio-organic fertilizer for liquorice and preparation method thereof

A bio-organic fertilizer and licorice technology, which is applied in the preparation of organic fertilizers, botany equipment and methods, and the treatment of bio-organic parts, can solve the problems of low nutrient content, different degrees of decomposition, and inability to meet the needs of high-yield and stable-yield licorice. Achieve the effect of increasing licorice yield and high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

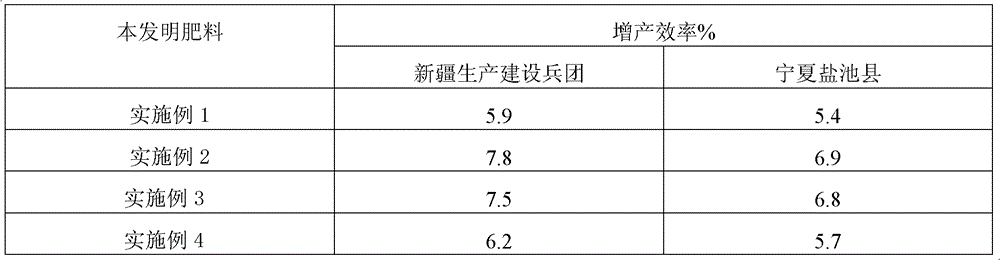

Examples

preparation example Construction

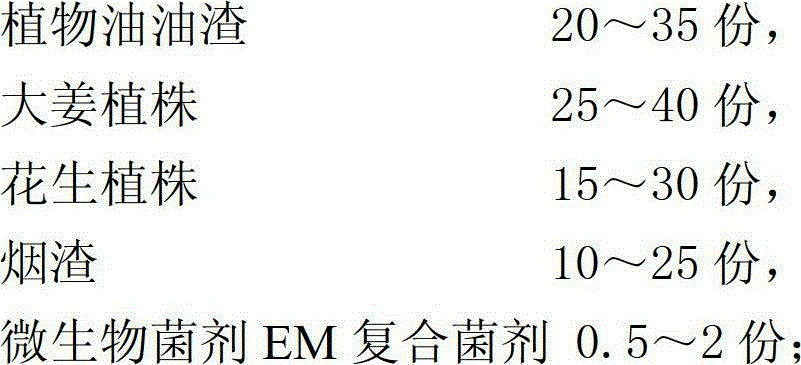

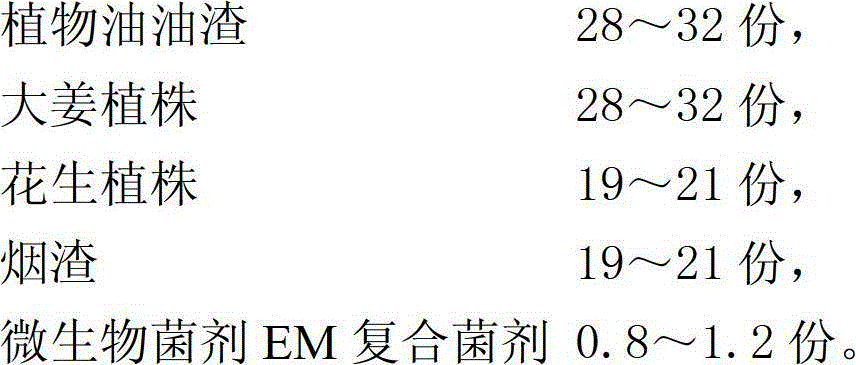

[0025] The preparation method of special biological organic fertilizer for Radix Glycyrrhizae of the present invention, the steps are as follows:

[0026] (1) Ginger plant and peanut plant are dried and crushed to a length of ≤ 1 cm; the soot residue is crushed to a particle size of ≤ 20 mesh; set aside;

[0027] (2) According to the ratio, take one-half of the vegetable oil residue, one-third of the ginger plant, one-half of the peanut plant, one-third of the tobacco residue, and one-half of the microbial agent EM compound bacterial agent , mix evenly; adjust the moisture content of the mixture to be 60-65wt%, count when the temperature rises to 55°C, accumulate and ferment for 5-7 days; turn over the pile, time when the temperature rises to 50°C again, accumulate and ferment for 5-7 days.

[0028] (3) Take one-half of the vegetable oil residue, one-third of the ginger plant, one-half of the peanut plant, one-third of the tobacco residue, and one-half of the microbial agent E...

specific Embodiment approach

[0041] The present invention will be further described below in conjunction with the examples, but not limited thereto. The amounts and parts of raw materials in the examples are parts by mass, and all percentages are percentages by mass.

[0042] Soybean oil residue, rapeseed oil residue, and peanut oil residue are all produced by Shandong Everbright Sun Moon Co., Ltd.; microbial fermentation agent EM composite agent is produced and sold by Jiangxi Tianyi Biotechnology Development Co., Ltd.

Embodiment 1

[0043] Embodiment 1: Glycyrrhizae special bio-organic fertilizer, raw material composition is as follows:

[0044] Peanut oil residue 20kg,

[0045] Ginger plant 40kg,

[0046] Peanut plants 30kg,

[0047] Smoke residue 10kg,

[0048] Microbial agent EM composite bacterial agent 0.5kg.

[0049] Preparation:

[0050] (1) Ginger plants and peanut plants are dried and crushed to less than 1 centimeter in length; soot residue is crushed to a particle size of ≤20 mesh;

[0051] (2) get peanut oil residue 10kg, crushed ginger plant 13.3kg, peanut plant 15kg, tobacco residue 3.3kg, microbial bacterial agent EM composite bacterial agent 0.25kg, mix homogeneously; adjust the moisture of mixture to be 60wt%, temperature rise Count when the temperature reaches 55°C, pile up and ferment for 7 days; turn over the pile, count when the temperature rises to 50°C again, pile up and ferment for 5 days.

[0052](3) Get peanut oil residue 10kg, ginger plant 13.3kg, peanut plant 15kg, tobacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com