Extraction method of rose crude polysaccharide

An extraction method and technology of crude polysaccharides, applied in the field of extraction of rose crude polysaccharides, can solve problems that have not yet been discovered, and achieve the effects of good organizational structure and appearance, stable product properties, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Pretreatment of raw materials

[0031] Crush the rose dregs, weigh 25g, soak in water for 12 hours and then filter, discard the filtrate to remove oligosaccharides; keep the pH of the original solution during pretreatment, which is about 6.4.

[0032] (2) Raw materials for acetone washing: add the soaked rose flower dregs to the same volume (w / v) of acetone solution, wash repeatedly for 3 times, filter, and discard the filtrate to remove part of the pigment and polyphenols in it.

[0033] (3) Extraction of crude polysaccharides from roses: add the above-mentioned washed rose residues to 750g of water at a material-to-water ratio of 1:30 (w / w), and reflux leaching in a water bath at 90°C for 4 hours.

[0034] (4) Second leaching: After the first leaching, filter to obtain the filtrate, then add 750g of water to extract the filter residue for 2 hours. After the extraction, the two filtrates were combined.

[0035] (5) Concentration: Concentrate the filtrate obtained...

Embodiment 2

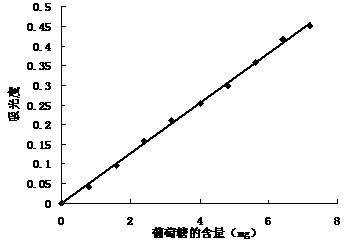

[0041] The content of the polysaccharide in the extracted rose crude polysaccharide is detected by the phenol-sulfuric acid method: the curve is as follows figure 1 .

[0042] The rose polysaccharide sample is a band in agarose gel electrophoresis, indicating that rose polysaccharide is a relatively uniform acidic polysaccharide.

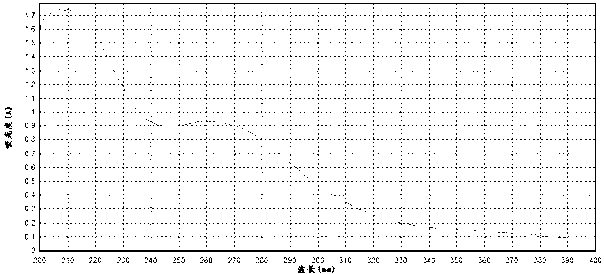

[0043] The ultraviolet absorption spectrum figure of gained rose crude polysaccharide is as figure 2 shown. Using a UV-visible spectrophotometer, the rose polysaccharide sample has a maximum absorption peak around 220 nm, and at the same time, there are protein and nucleic acid absorption peaks between 270-290 nm, indicating that there are proteins, pigments, or nucleic acids in the sample. Is a glycoprotein complex that binds pigments.

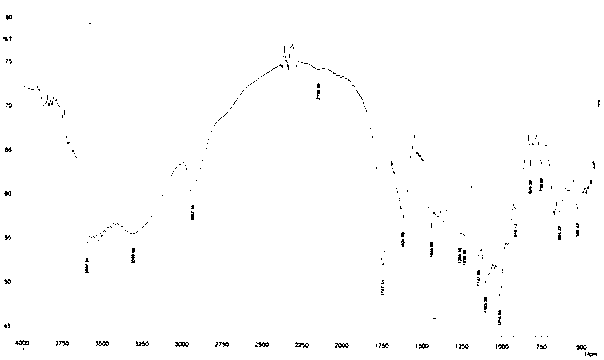

[0044] The infrared absorption spectrum figure of gained rose crude polysaccharide is as image 3 shown. The infrared spectrum of rose polysaccharide samples showed that rose polysaccharide had typical polysa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com