System and method for monitoring seizure and stuck failure of drill rod of rotary drilling rig

A technology of rotary drilling rig and monitoring system, which is applied to the automatic control system of drilling, drilling equipment, earth-moving drilling, etc., can solve the problems of no rotary drilling rig drill pipe, stuck rod failure, damaged drill pipe and power head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

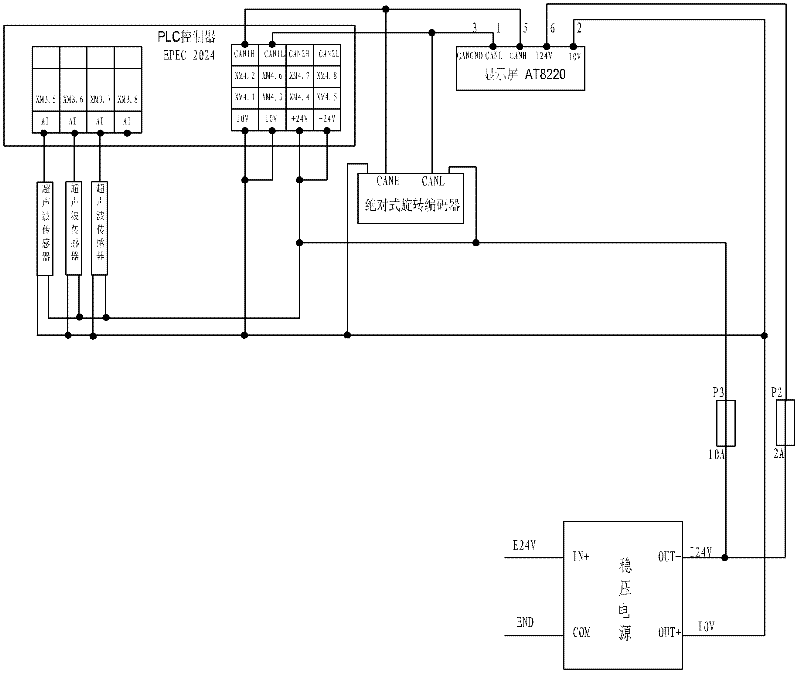

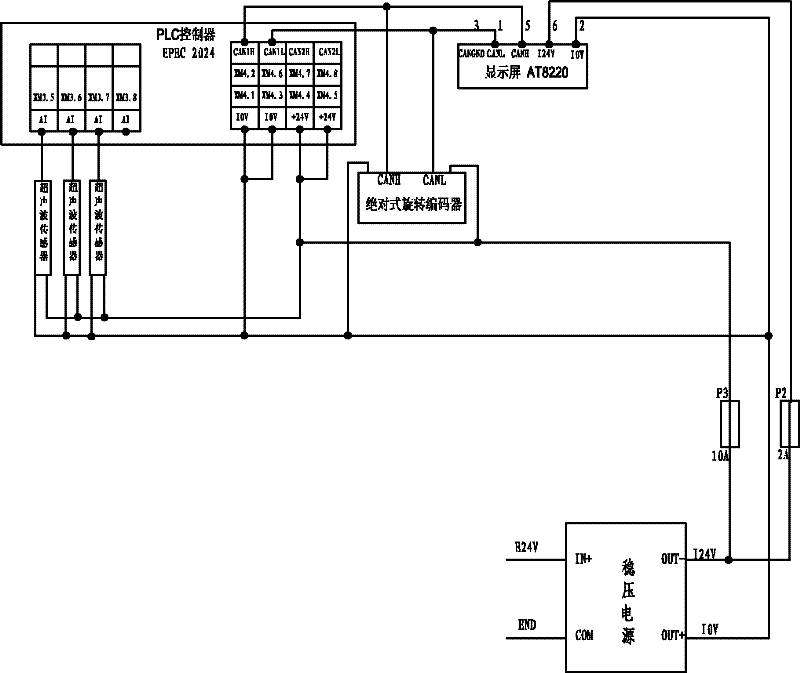

[0027] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0028] refer to figure 1 As shown, the monitoring system of the rotary drilling rig in this embodiment includes a rotary encoder for monitoring the first displacement of the drill bit relative to the ground, and a rotary encoder for monitoring the second displacement of the power head relative to the ground. Ultrasonic sensor A, two ultrasonic sensors B used to monitor the actual deformation of the upper tray buffer spring of the power head, and the PLC of the rotary drilling rig and the display with an alarm module on it, wherein the PLC is used for monitoring according to the received The first displacement and the second displacement obtain the total length of the drill rod, obtain the weight of the total length of the drill rod according to the total length of the drill rod and the length and weight of each drill rod in the drill rod, and obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com