Continuous culture for 1,3-propanediol production using high glycerine concentration

A propylene glycol, high-concentration technology, applied in 1 field, can solve problems such as expensive, discontinuous, and unable to give glycerin performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

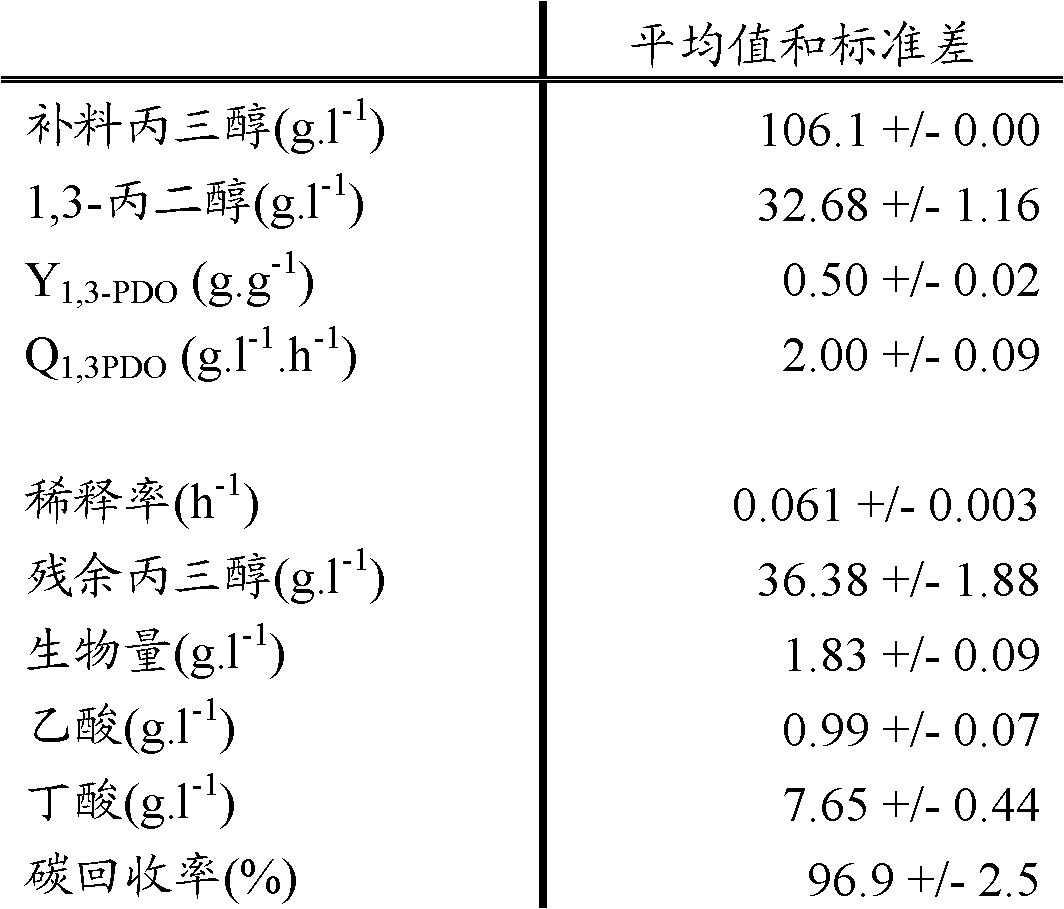

[0028]The present invention relates to a method for the production of 1,3-propanediol in a continuous fermentation process of glycerol, comprising culturing on a medium a production microorganism allowing the conversion of glycerol to 1,3-propanediol, and Recovery of 1,3-propanediol, characterized in that the medium comprises a high concentration of technical glycerol comprising glycerol, and wherein the producing microorganism is a microorganism pre-adapted to grow in the presence of a high concentration of technical glycerol .

[0029] The term "microorganism" means a microorganism selected from the group consisting of bacteria, yeast and fungi. Preferably, said microorganism is a bacterium preferably selected from the group consisting of Enterobacteriaceae, Bacillaceae, Clostridiaceae, Streptomycetaceae and Corynebacteriaceae. More preferably, the bacteria are selected from the group consisting of Escherichia sp. (preferably Escherichia coli), Klebsiella sp. (preferably Kl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com