Method for mechanically humidifying and moisturizing warehoused tobacco leaves in dry and cold season

A tobacco leaf and machine technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf moisture loss, waste, and no inhibition of moisture and heat transfer of tobacco leaf stacking, etc., and achieves processing resistance and economical properties improvement. The method is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for mechanically adjusting and moistening stored tobacco leaves in dry and cold seasons, comprising the following steps:

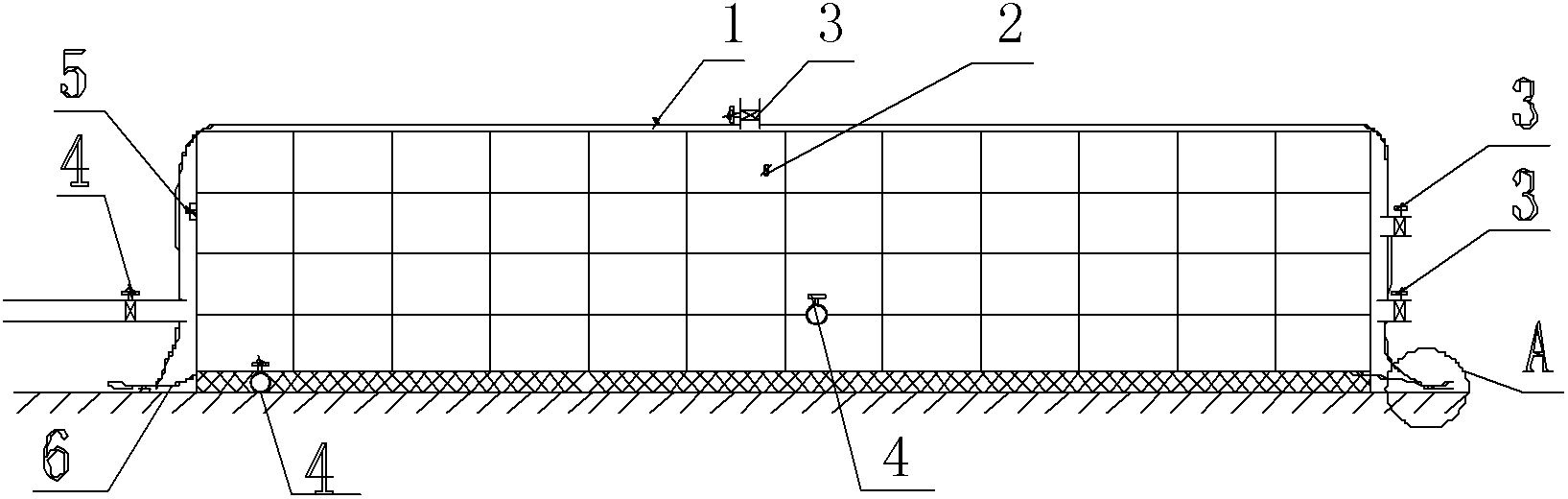

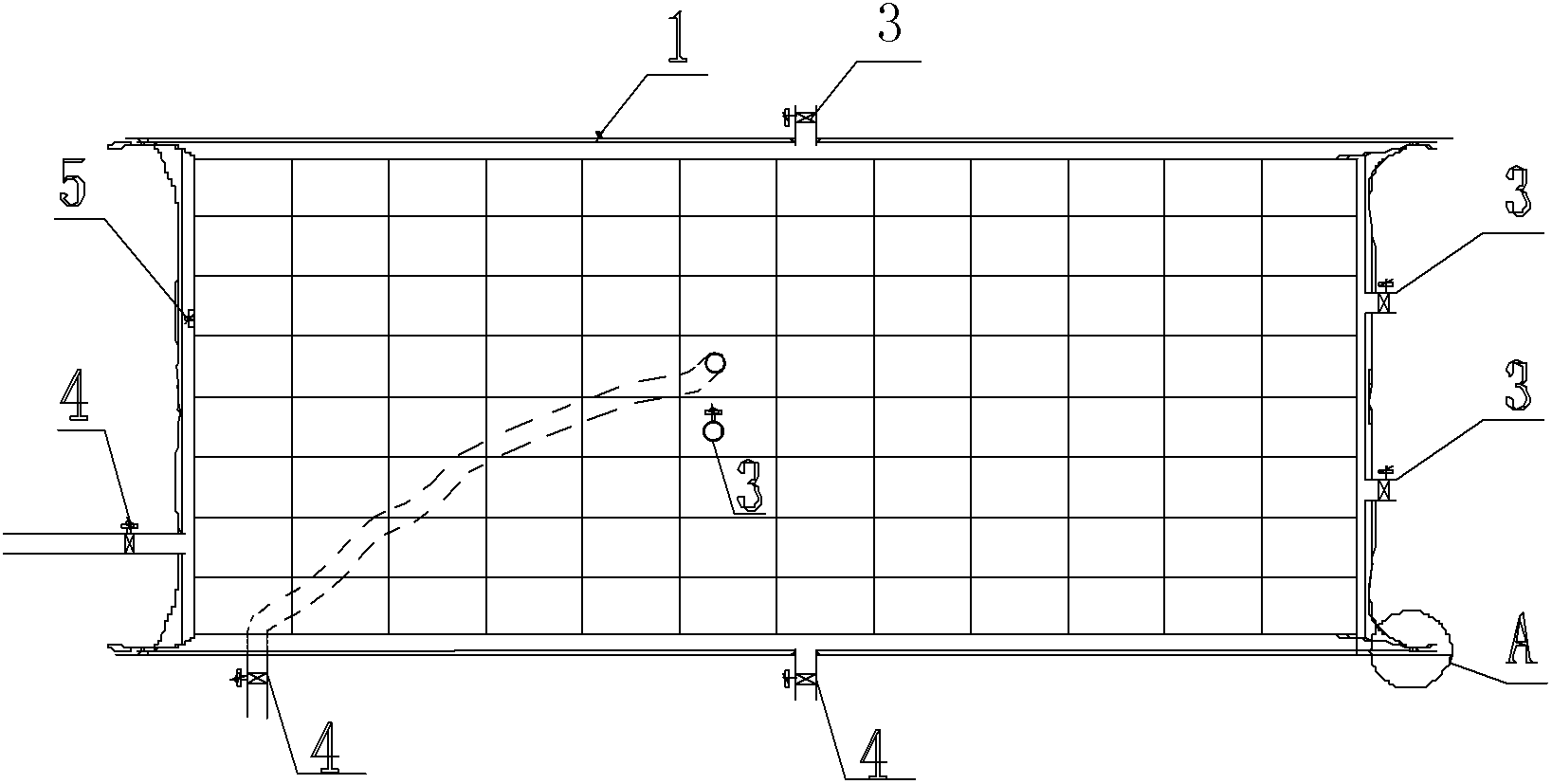

[0059] 1), build a plastic tent sealing system in the tobacco leaf warehouse that can mechanically regulate the internal storage environment of the tobacco leaf stack (that is, construct a six-sided sealed tobacco leaf stacking sealed space that can mechanically regulate the storage environment, such as Picture 1-1 , Figure 1-2 , figure 2 shown), including the following steps:

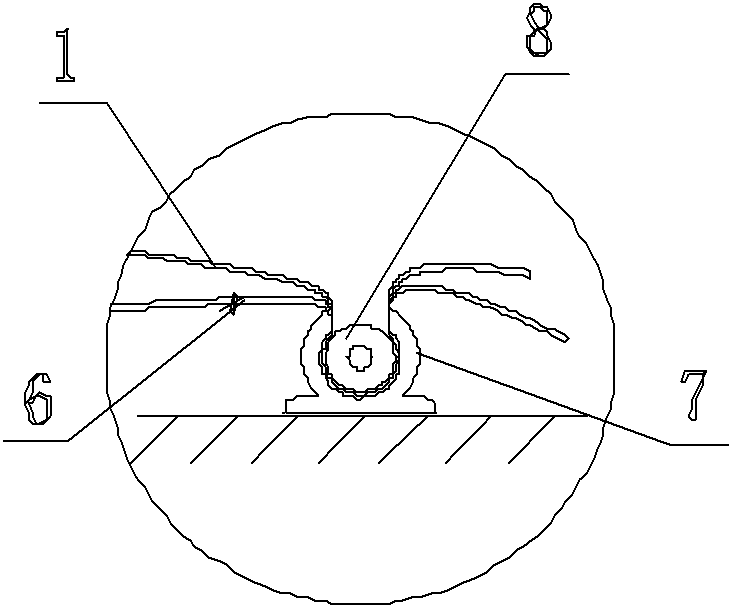

[0060] 1. A main blast pipe and a main exhaust pipe are respectively arranged in the tobacco leaf warehouse, and several ventilation branch pipes are respectively drawn out on the main blast pipe and the main exhaust pipe (the several ventilation branch pipes described can be 2-100 ventilation pipes). Branch pipe, determined according to the size of the storage), there is a valve at the end of the ventilation branch pipe, and a ventilation hose is connected to t...

Embodiment 2

[0088] Basically the same as Example 1, the difference is:

[0089] After completing step 1) in the tobacco leaf warehouse, construct a plastic tent sealing system that can mechanically regulate the internal storage environment of the tobacco leaf stack (construct a series of plastic tent sealing spaces that can mechanically regulate the internal storage environment of the tobacco leaf stack in the tobacco leaf warehouse), In the dry and cold season when the temperature is lower than 10°C, the following methods are used to achieve humidity adjustment, maintenance and quality improvement of stored tobacco leaves:

[0090] Relying on the method of parallel connection of mechanical humidifiers: In the closed tobacco warehouse, start the heating equipment inside the warehouse to keep the temperature in the warehouse above 10°C and below 25°C; The air control joint is connected with the ventilation branch pipe (blast branch pipe) on the main blast pipe in the adjacent tobacco leaf ...

Embodiment 3

[0095] Basically the same as Example 1, the difference is:

[0096] After completing step 1) in the tobacco leaf warehouse, construct a plastic tent sealing system that can mechanically regulate the internal storage environment of the tobacco leaf stack (construct a series of plastic tent sealing spaces that can mechanically regulate the internal storage environment of the tobacco leaf stack in the tobacco leaf warehouse), In dry and cold seasons when the temperature is lower than 10°C, the following methods are used to achieve humidity adjustment, maintenance and quality improvement of stored tobacco leaves:

[0097]Rely on mechanical humidifiers to humidify in series: In a closed tobacco warehouse, start the heating equipment inside the warehouse to keep the temperature in the warehouse above 10°C and below 25°C; The air intake control joint is connected with the ventilation branch pipe (blast branch pipe) arranged on the main blast pipe in the warehouse, while the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com