Matrix equal spacing extension device

An expansion device and equidistant technology, applied in metal processing and other directions, can solve the problems of large space occupied by the mechanism, unsuitable for large-scale use, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

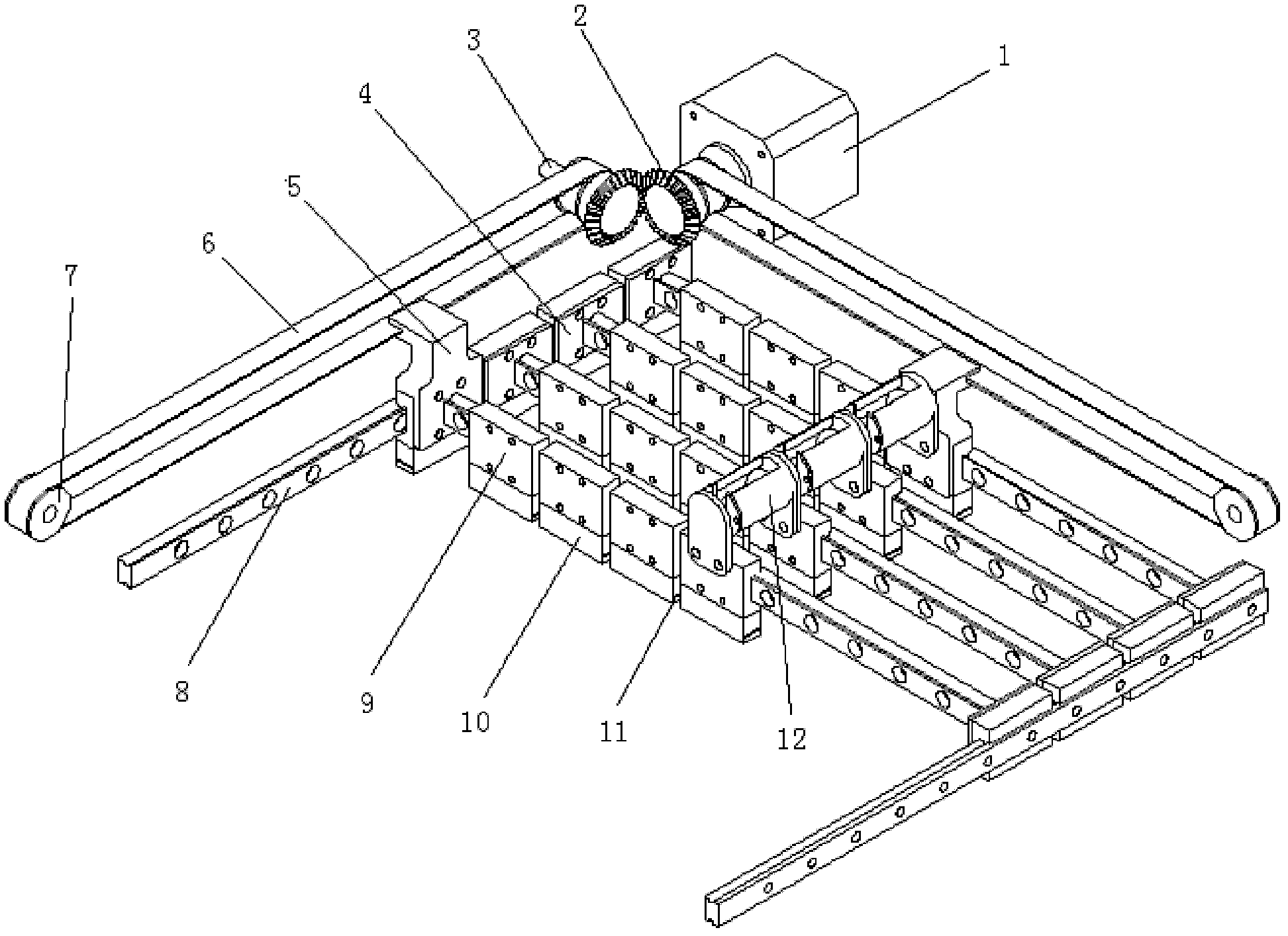

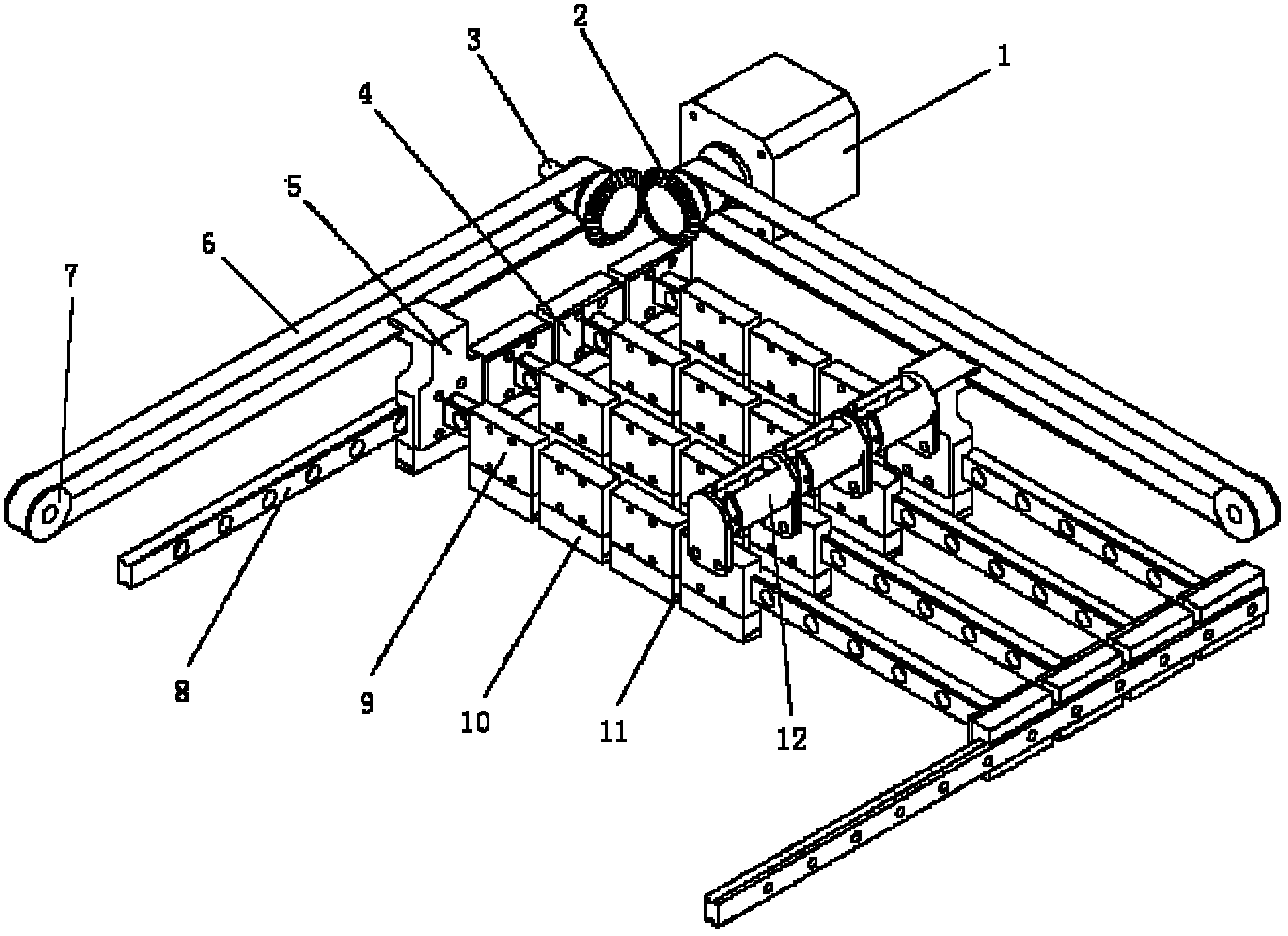

[0012] The present invention will be further described below in conjunction with accompanying drawing:

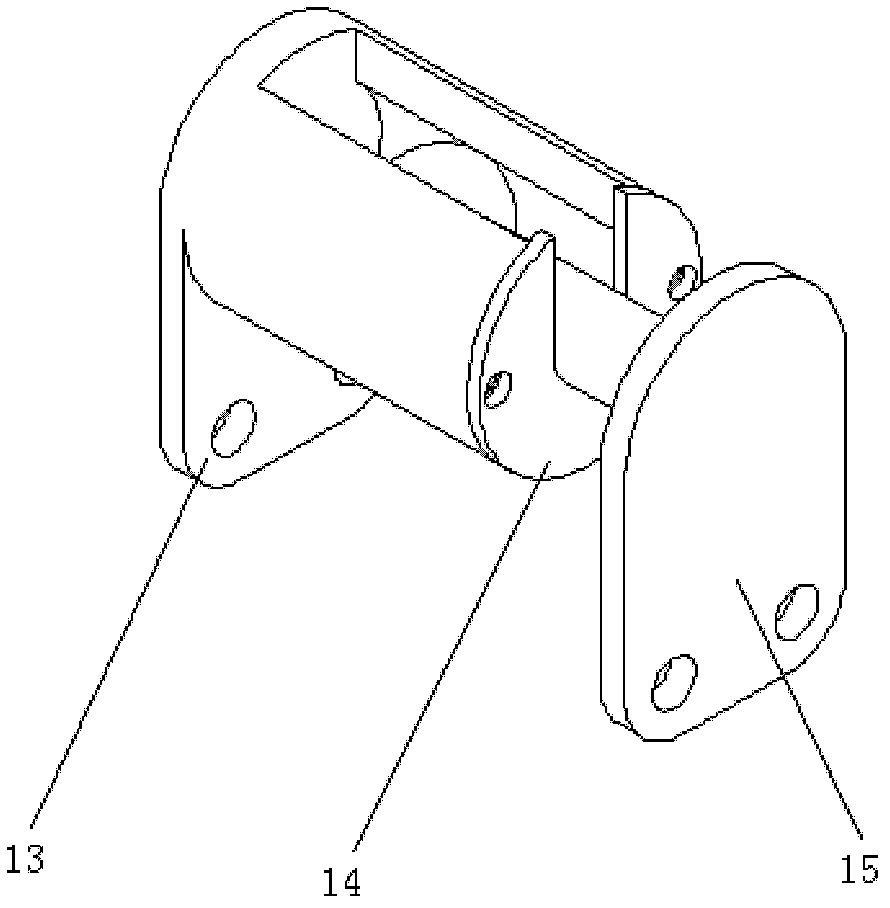

[0013] Such as figure 1 As shown, the straight bevel gear 2 and the synchronous toothed belt pulley 7 are installed on the motor shaft, and another straight bevel gear and the belt pulley are installed on the short axis with the motor shaft at an angle of 90°, and the belts are mounted on them respectively. The guide rails are arranged as four in the X-axis direction and two in the Y-axis direction, and four slide blocks 9 are installed on each guide rail. Small belt clip 10 is installed below each slide block. Each guide rail of the X-axis is welded with the guide rail connecting piece 4 or the belt clip 5, and is installed on the slide block of the Y-axis guide rail through bolt connection. The farthest slide block on the X-axis guide rail is equipped with conduit 12 and belt clip 5 . The two belt clips are mounted on the two timing belts respectively. Every 4 slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com