High-precision continuous feeding system

A feeding system, high-precision technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of not ensuring environmental protection requirements, falling and hurting people, running materials, etc., to ensure the effect of high-precision continuous quantitative conveying of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

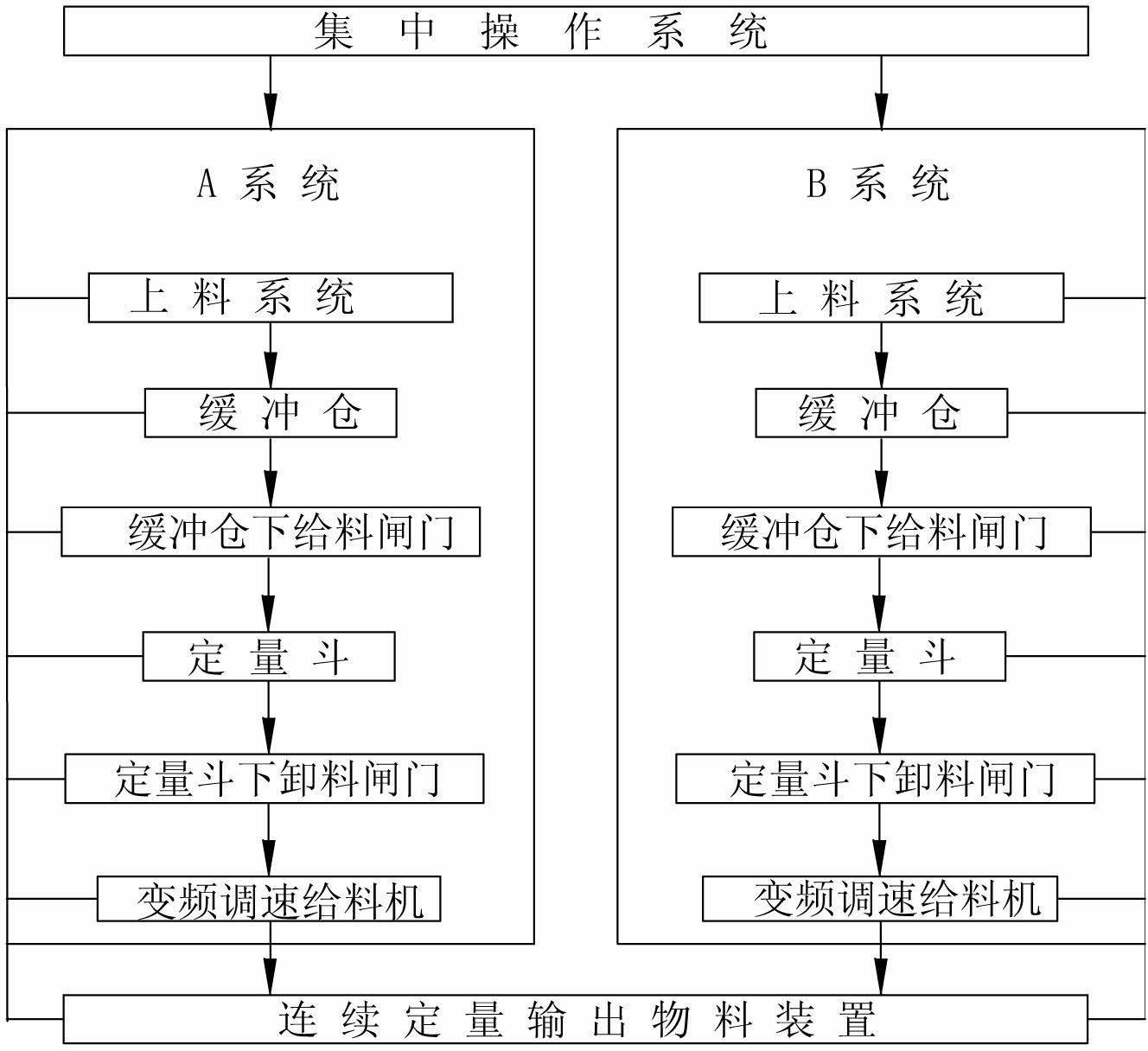

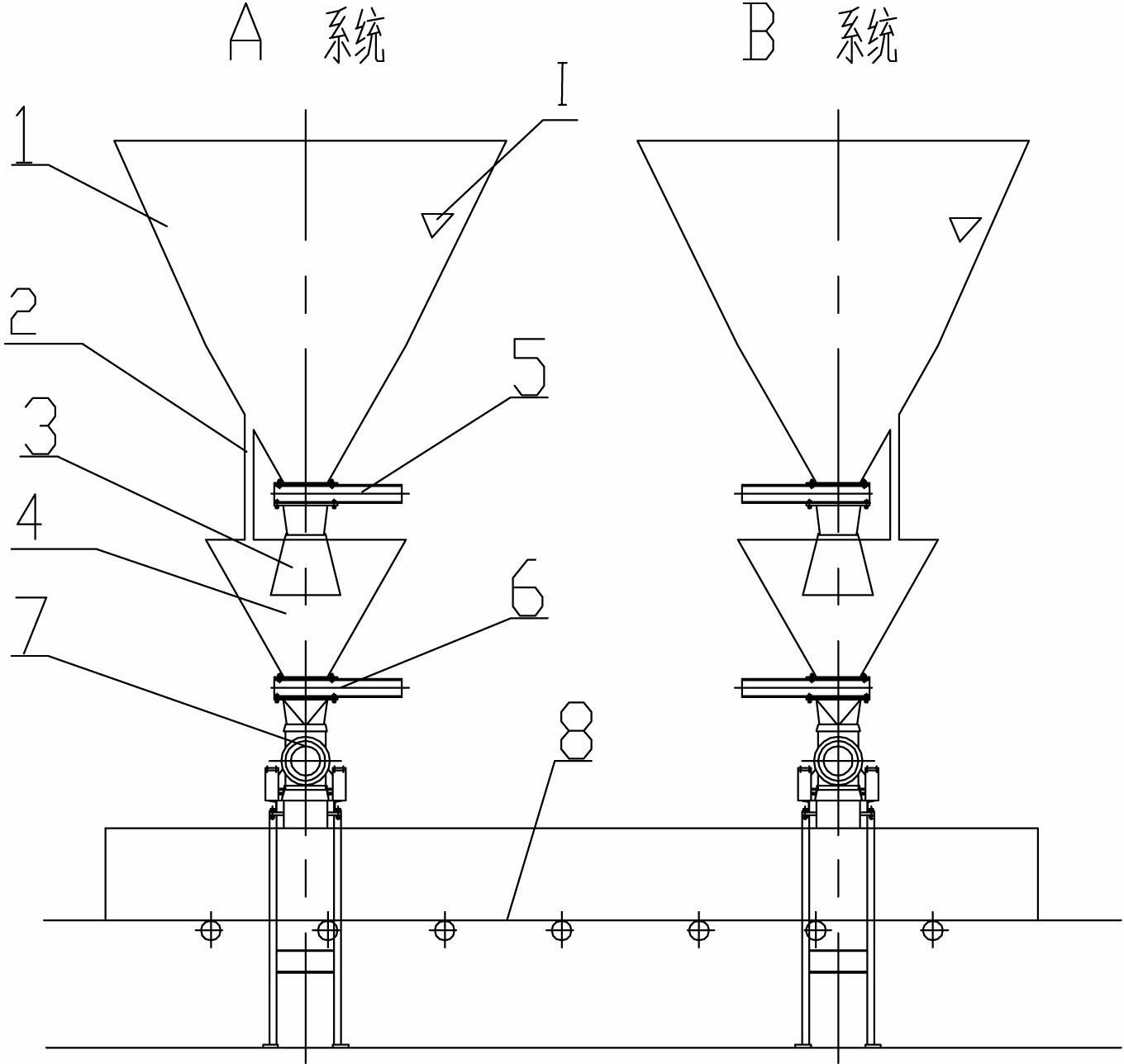

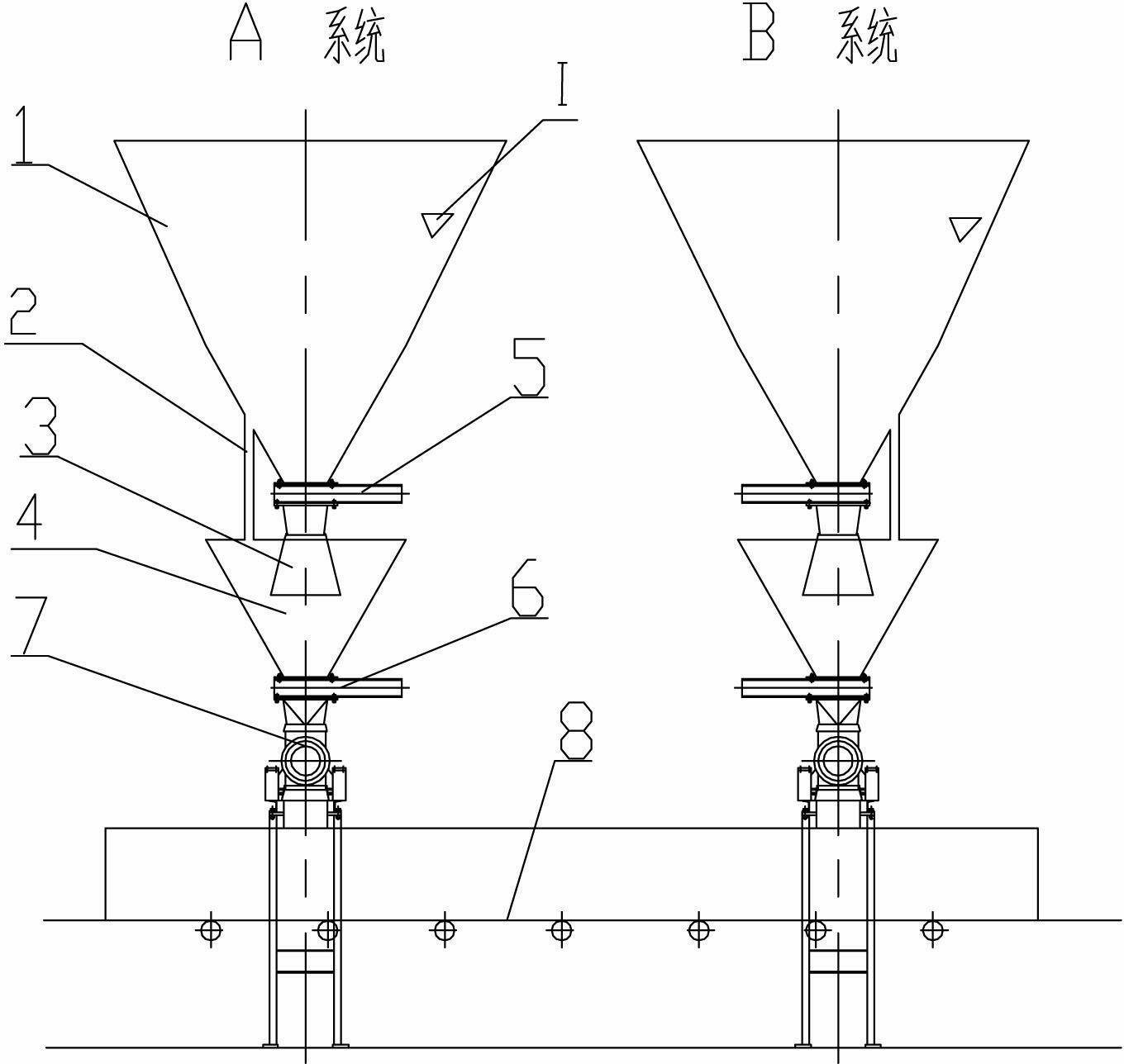

[0017] Such as figure 1 , 2 As shown, taking the A system in the figure as an example, the high-precision continuous feeding system of the present invention consists of a feeding device, a buffer bin 1 connected to the feeding device, and a feeding gate connected to the buffer bin 1 5. Quantitative hopper 4 connected to this feeding gate 5, discharge gate 6 connected to this quantitative hopper 4, feeder 7 connected to this discharge gate 6 and the feeder 7 lower part The A system composed of the continuous quantitative output material device 8 and the automatic control device connected with the A system are characterized in that at least one B system with the same structure as the A system is arranged side by side with the A system. Both system A and system B are connected with the automatic control device, and the automatic control device is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com