Hot plug type electric connector

A plug-in technology for electrical connectors, applied in the field of electrical connector structure design, can solve the problems of complex structure of radiators, cumbersome installation and disassembly operations, etc., and achieve the effects of convenient installation and disassembly operations, good stability and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

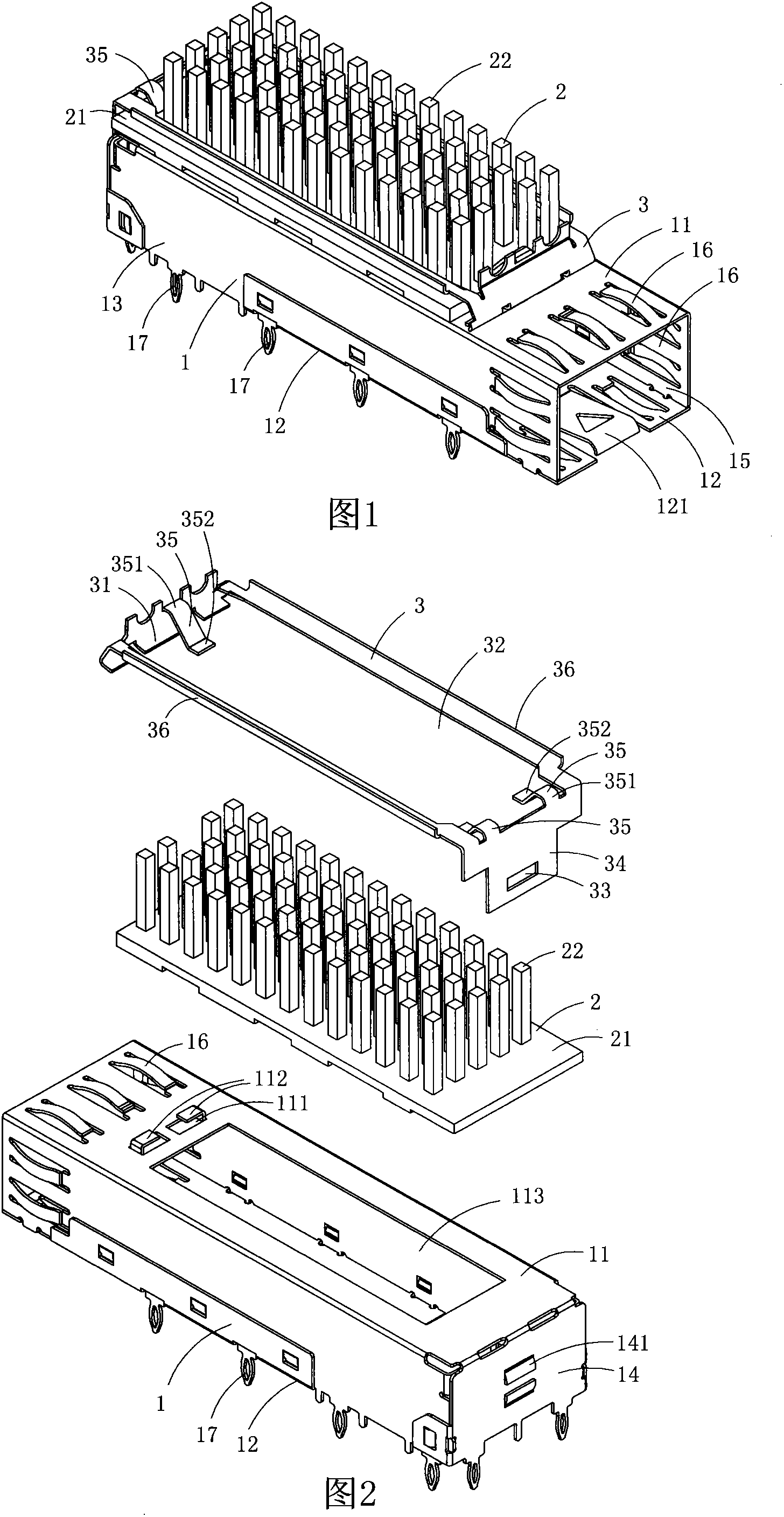

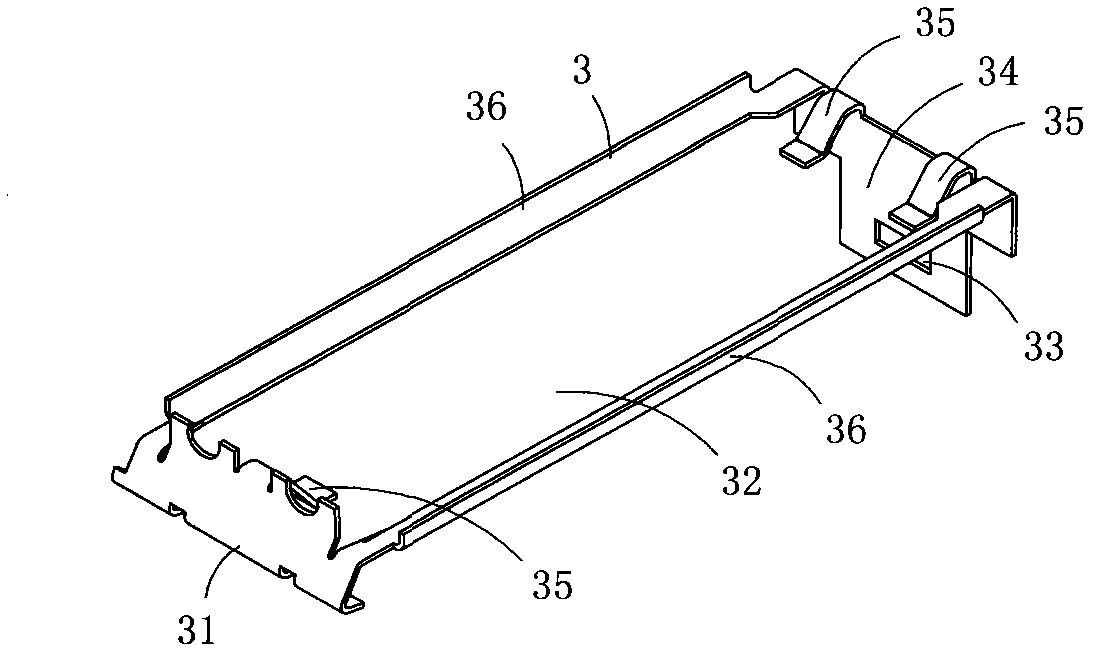

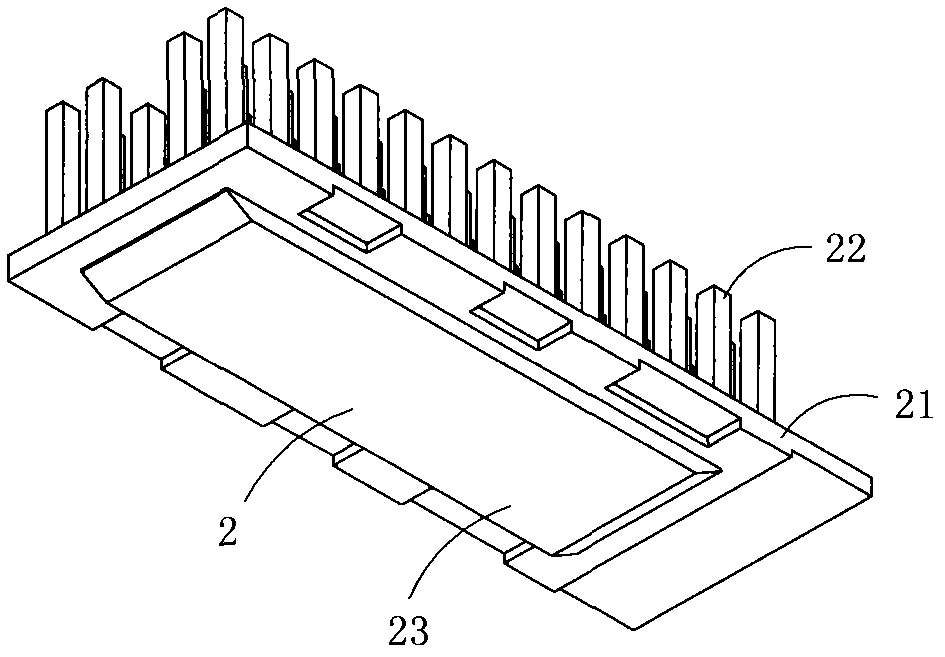

[0023] Figure 1 to Figure 4 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 An exploded view of the shown hot-swappable electrical connector; image 3 for figure 1 A schematic diagram of a three-dimensional structure of the fixing clip in the shown hot-swappable electrical connector; Figure 4 figure 1 A schematic diagram of a three-dimensional structure of the heat dissipation module in the hot-swappable electrical connector shown.

[0024] The invention discloses a hot-swappable electrical connector, comprising a housing body 1, a heat dissipation module 2 arranged on the housing body 1, and a fixing clip 3 for fixing the heat dissipation module 2 on the housing body 1 The housing body 1 includes a top wall 11, a bottom wall 12, two side walls 13 and a rear wall 14, and the top wall 11, the bottom wall 12, the two side walls 13 and the rear wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com