Uv liquid steriliser

A fluid and fluid treatment technology, applied in the field of disinfection of beverages and liquid food, can solve the problems of high cost, no commercial value, energy consumption, etc., and achieve high reliability, constant and fully mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

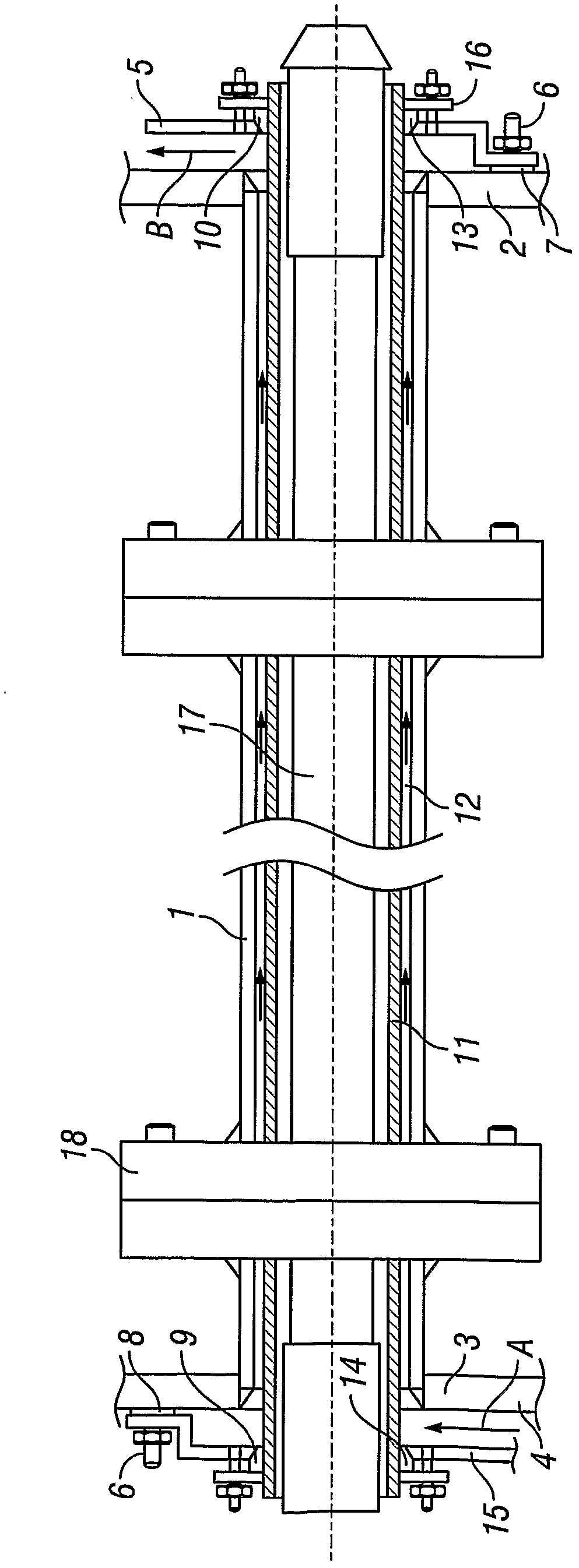

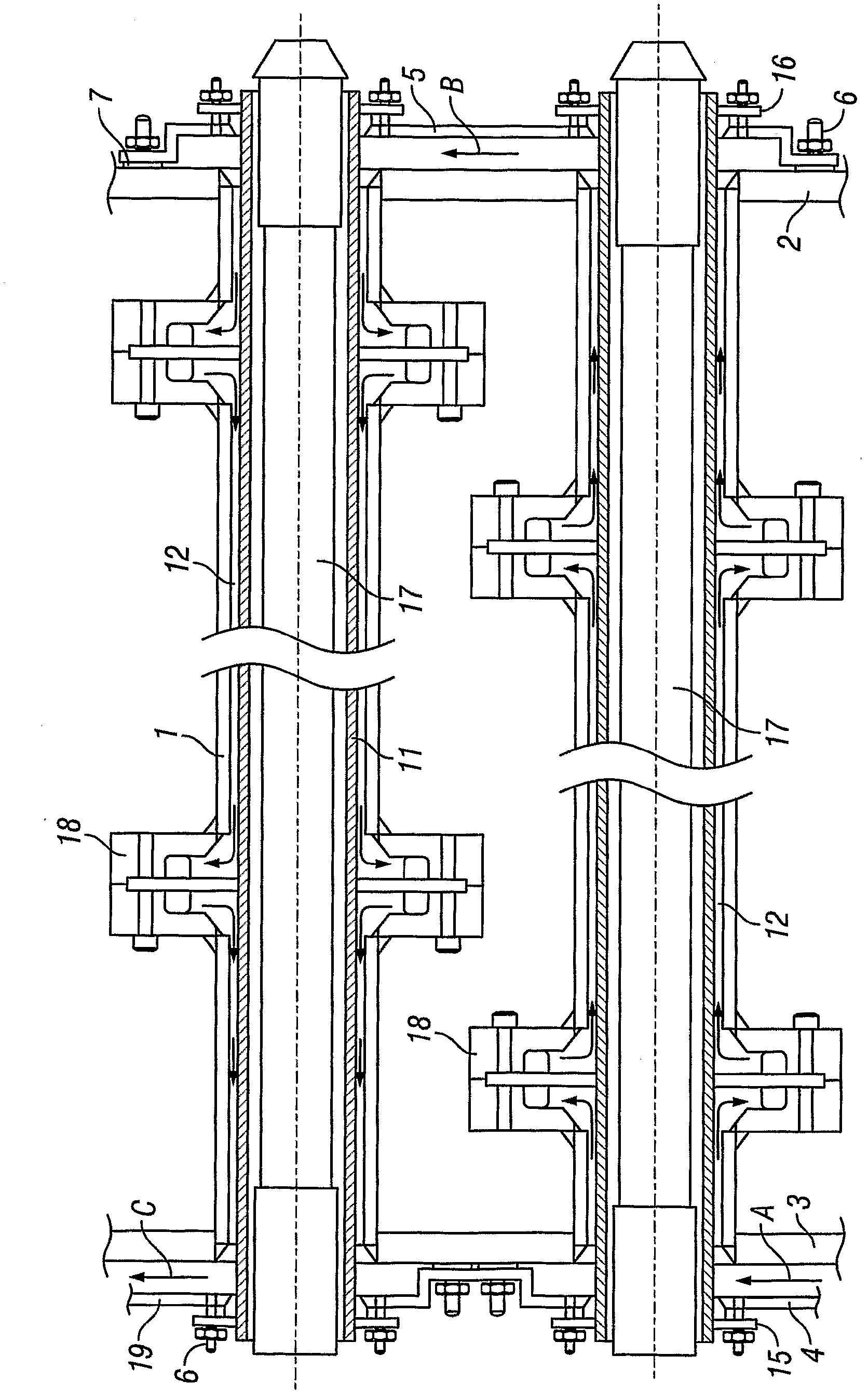

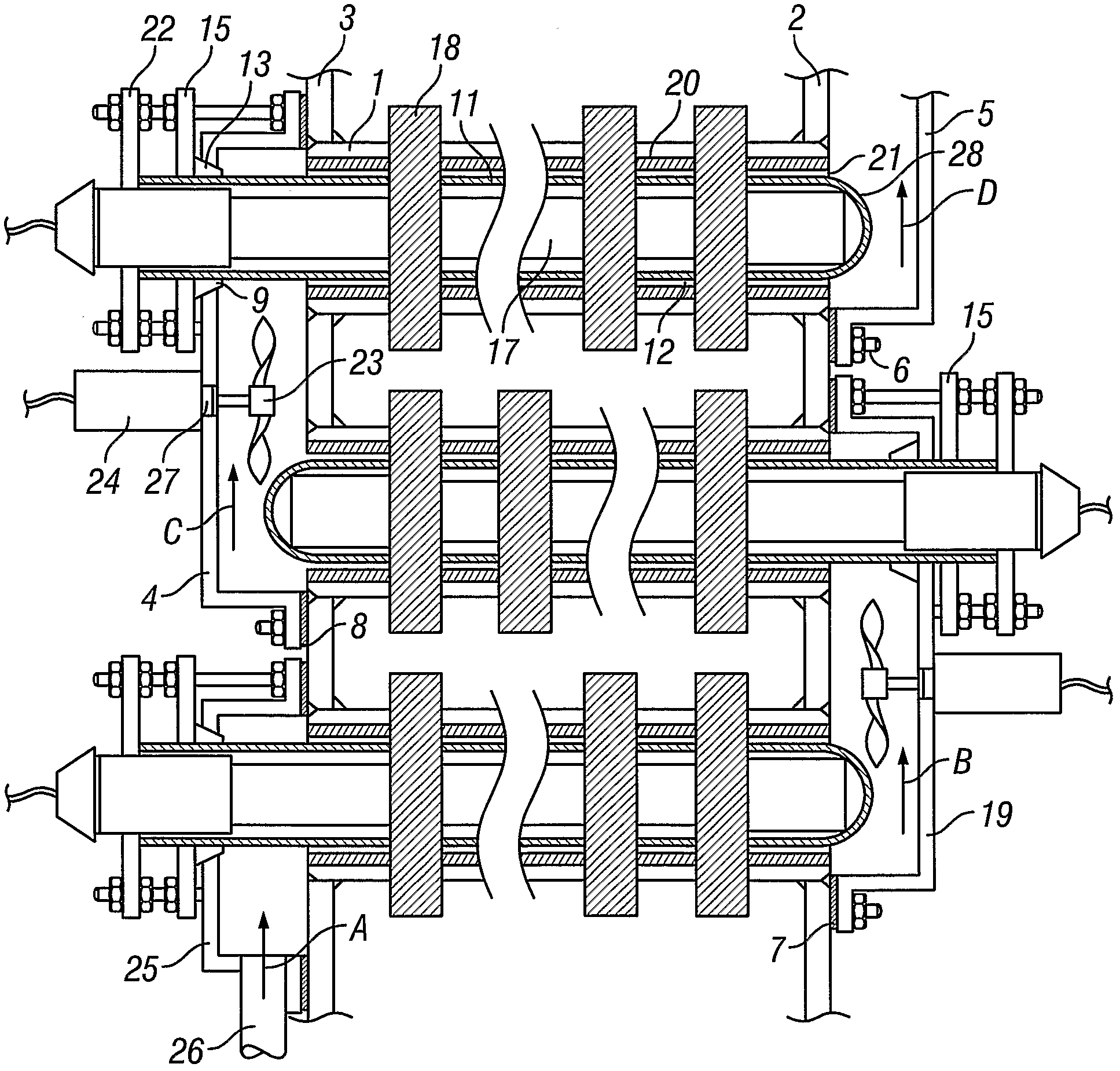

[0048] Refer to the attached figure 1 , in the first embodiment of the fluid disinfection device, the reaction chamber 1 is connected between the end plates 2&3. Preferably, the reaction chamber is welded to the end plates such that the weld is polished to provide a hygienic food grade seal.

[0049] An inlet manifold 4 and an outlet manifold 5 are located adjacent to the reaction chamber, said inlet manifold and said outlet manifold being connected to end plates 2 & 3 by fasteners 6 . The inlet manifold 4 and outlet manifold 5 are made watertight by seals 7 & 8 sandwiched between the inlet and outlet manifolds 4 & 5 and the end plates 2 & 3 .

[0050] A tubular sleeve 11 is longitudinally centered and concentrically positioned within the reaction chamber 1 such that it protrudes through the end plates 2 & 3 and through holes 9 & 10 in the inlet and outlet manifolds 4 & 5 .

[0051] Preferably, the tubular sleeve is a good transmitter of germicidal wavelengths (220nm-280nm)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com