High ground clearance vehicle drive axle

A vehicle-driven, high-ground-clearance technology, which is applied to vehicle parts, axles, wheels, etc., can solve the problems of low equipment utilization, large investment, and easy subsidence of tractors, and achieve the effect of compact structure and improved ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

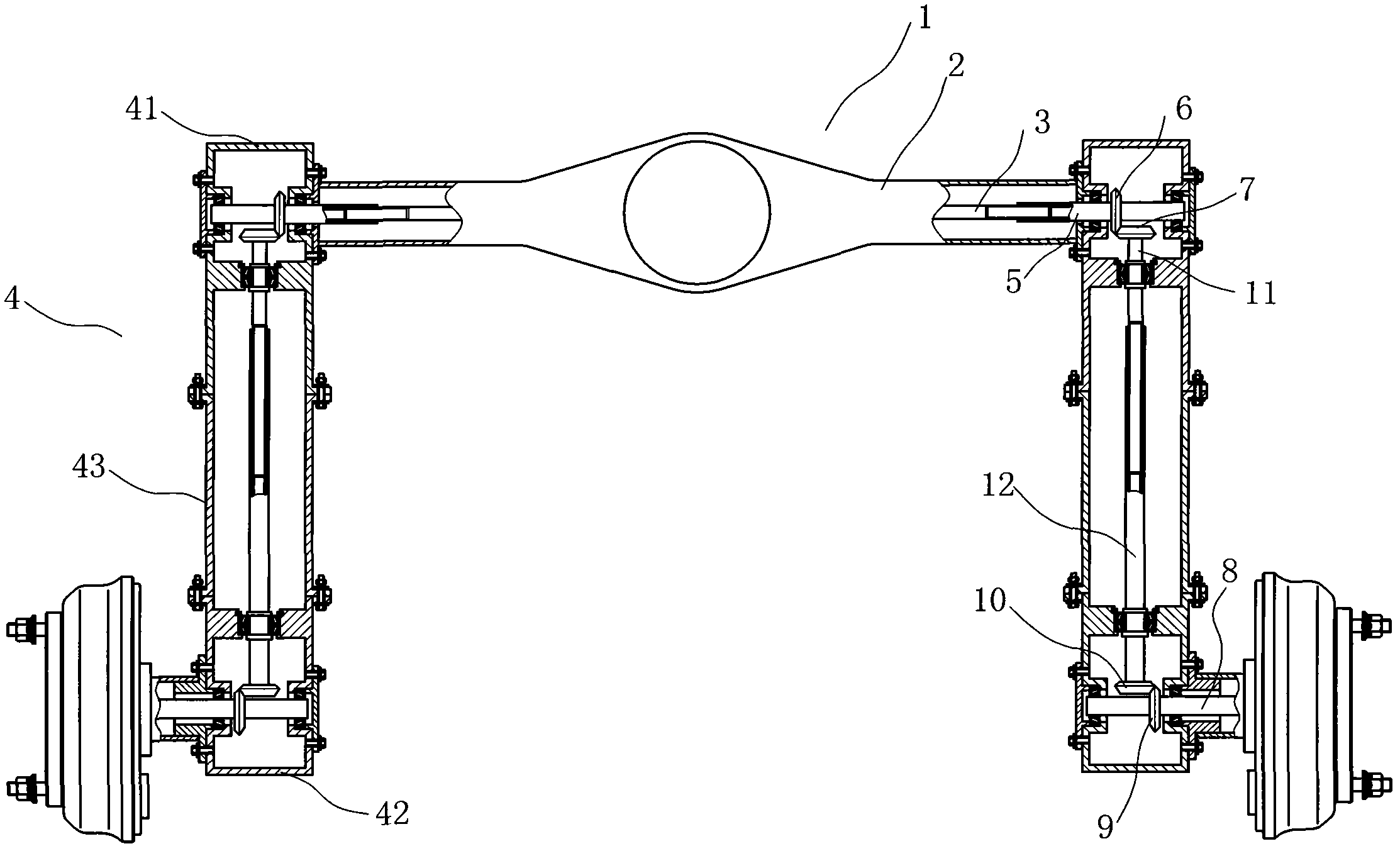

[0015] like figure 1 As shown, the high ground clearance vehicle drive axle includes a housing 1, a power output shaft 3 is installed in the bridge tube 2 on both sides of the housing 1, and side transmission boxes 4 are fixedly installed at both ends of the housing 1, respectively. The side transmission box 4 includes:

[0016] Upper box body 41, the drive shaft 5 of the side transmission box is installed in the rotation of the upper box body 41, and the drive shaft 5 of the side transmission box is connected with the spline of the power output shaft 3; An upper driving bevel gear 6 is fixedly installed, and an upper driven bevel gear 7 meshing with the upper driving bevel gear 6 is also rotatably installed in the upper box 41;

[0017] The lower box body 42, the wheel half shaft 8 is installed in rotation in the said lower box body 42, the lower driven bevel gear 9 is fixedly installed on the said wheel half shaft 8, and the lower driven bevel gear 9 is also rotatably insta...

Embodiment 2

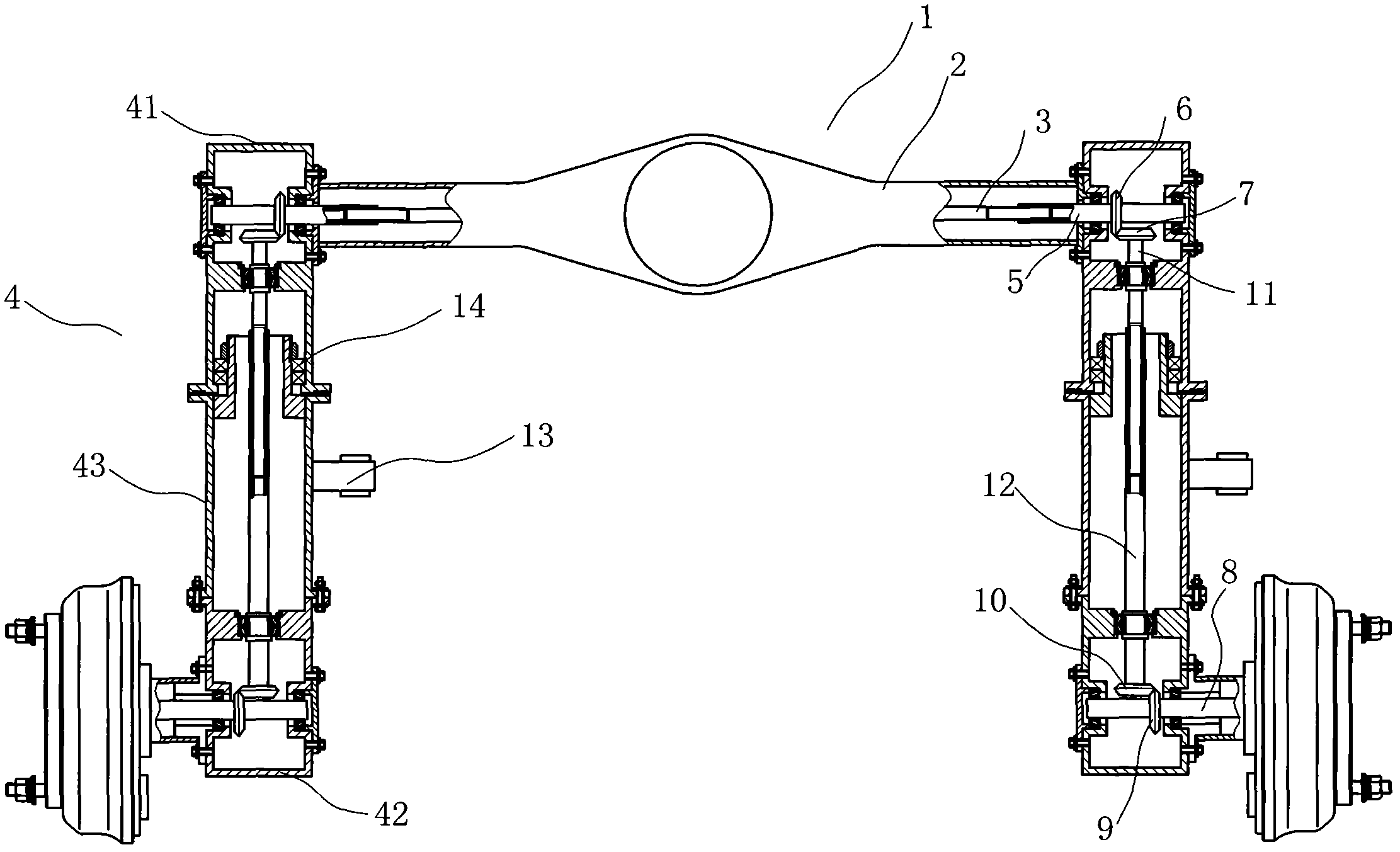

[0022] like figure 2 As shown, the structure of the second embodiment is basically the same as the structure of the first embodiment. The rotating device is installed on the upper box body 41, and the wheel steering arm 13 is fixedly arranged on the variable ground clearance box body 43; 41 between the bearings 14 .

[0023] The upper end of the variable clearance box 43 is installed on the upper box 41 through a rotating device, and the wheel steering arm 13 is fixed on the variable clearance box 43; the wheel steering arm can complete the wheel steering under the steering rod. Steering can be used as the steering drive axle of the vehicle, and the variable ground clearance box body 43 installed between the upper box body 41 and the lower box body 42 improves the ground clearance of the vehicle. The ground clearance of the vehicle can be changed, and the ground clearance can be adjusted according to the operating conditions. The adjustment is convenient and reliable to mee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap