Fluid-filled type vibration damping device

A vibration isolation and fluid technology, which is applied in the direction of power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as difficult safety valve deformation, spring characteristics, reduction of fluid flow, and easy cracking, etc., to achieve improved quietness, The effect of preventing abnormal sound and preventing the generation of abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

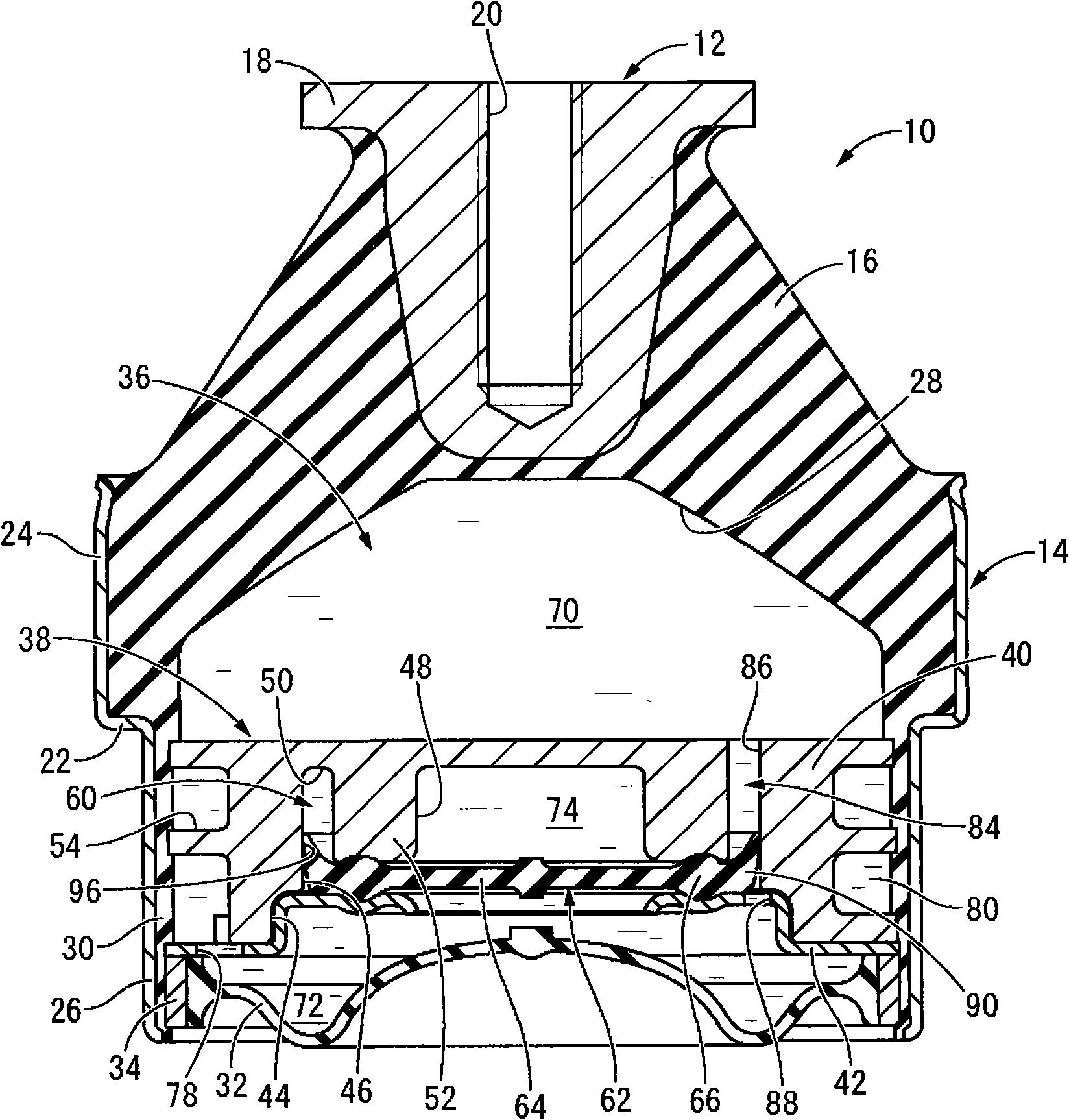

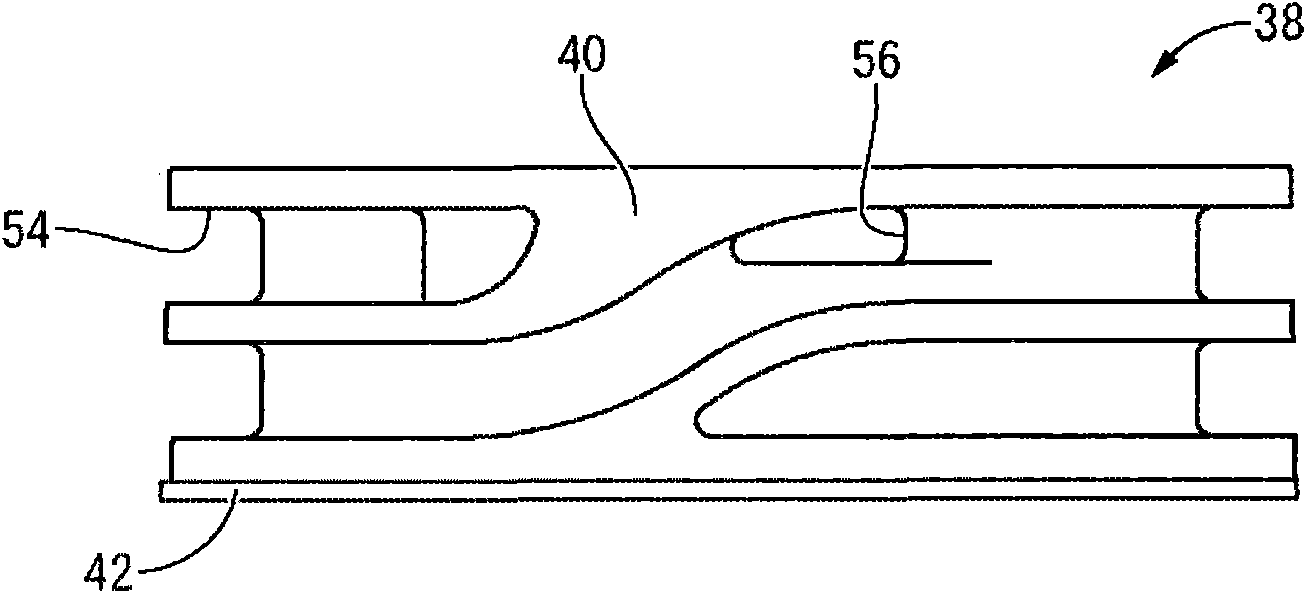

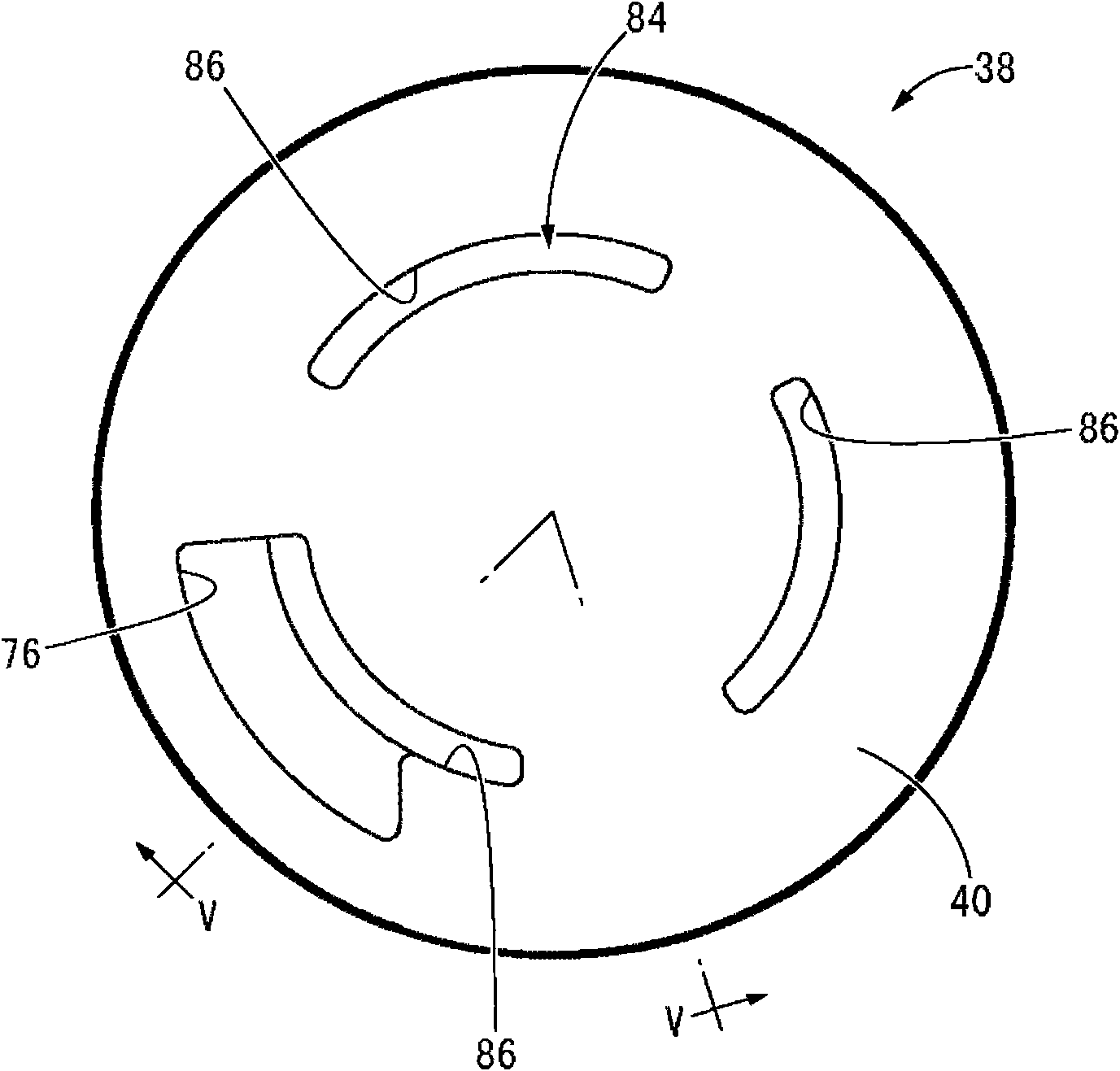

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] exist figure 1 In the figure, the engine mount 10 for automobiles which is one embodiment of the fluid-filled vibration isolation device of the structure which pertains to this invention is shown. The engine mount 10 has a structure in which a first mounting member 12 and a second mounting member 14 are connected by a main body rubber elastic body 16 . In addition, the first mounting member 12 is mounted on an unillustrated power unit, and the second mounting member 14 is mounted on an unillustrated vehicle body, whereby the power unit is vibration-isolated and supported by the vehicle body. In addition, in the following description, in principle, the up-down direction means figure 1 in the up and down direction.

[0037] In more detail, the first mounting member 12 has a solid substantially circular block shape, and a flange portion 18 protruding in a direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com