Plane main undercarriage space retraction/extension mechanism and retraction/extension method

A retractable mechanism and landing gear technology, applied in the chassis and other directions, can solve the problems of the landing gear door retractable mechanism and the complex control system, and achieve the effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

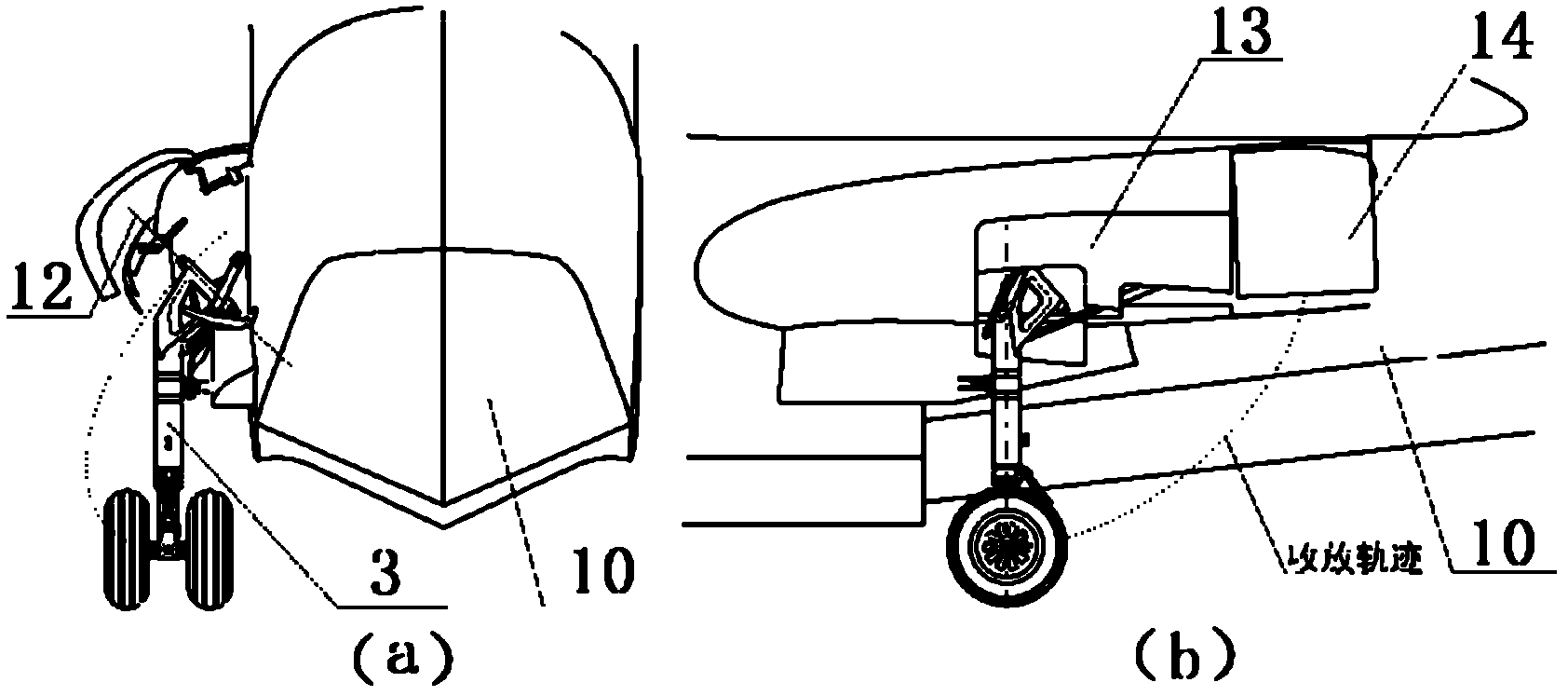

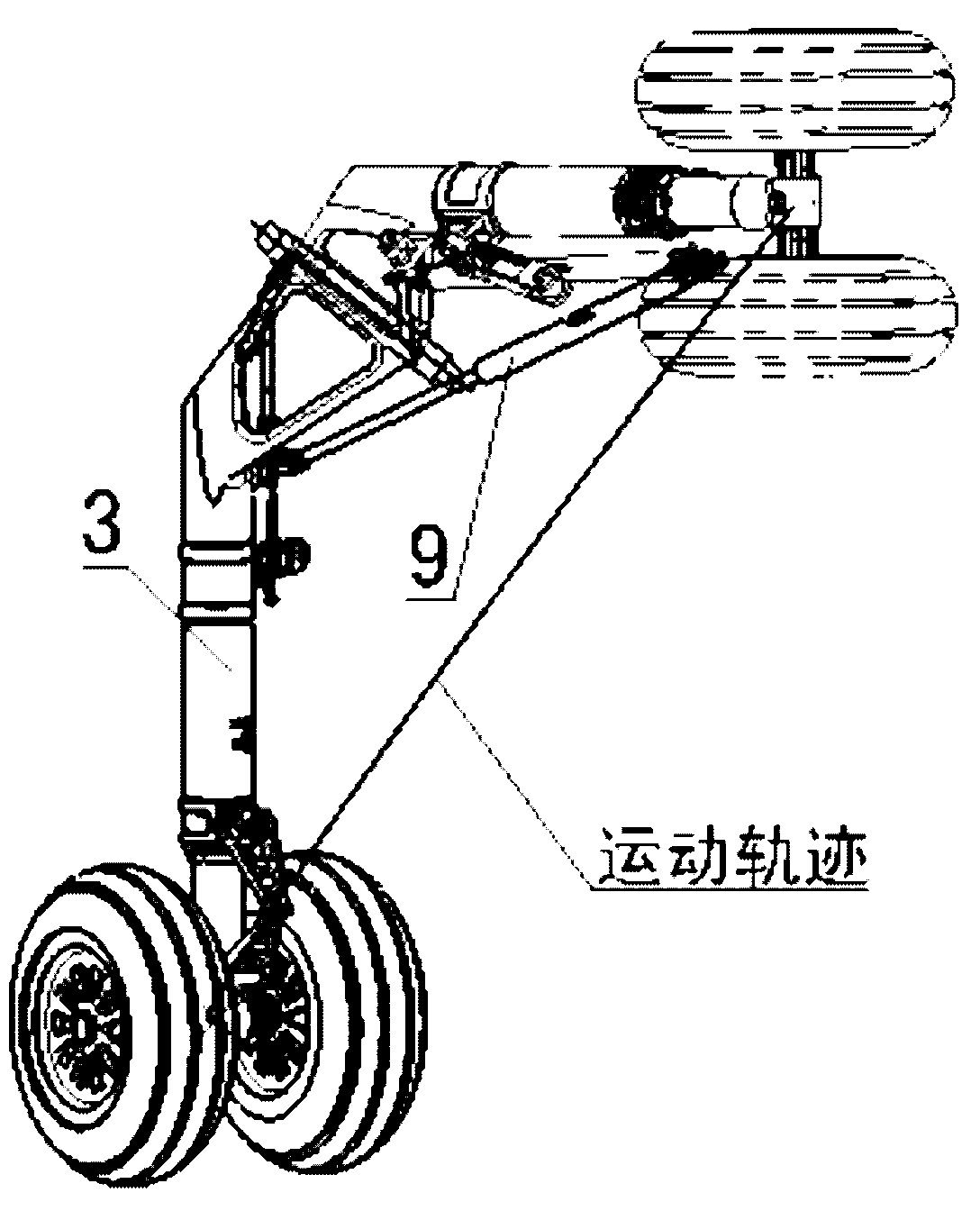

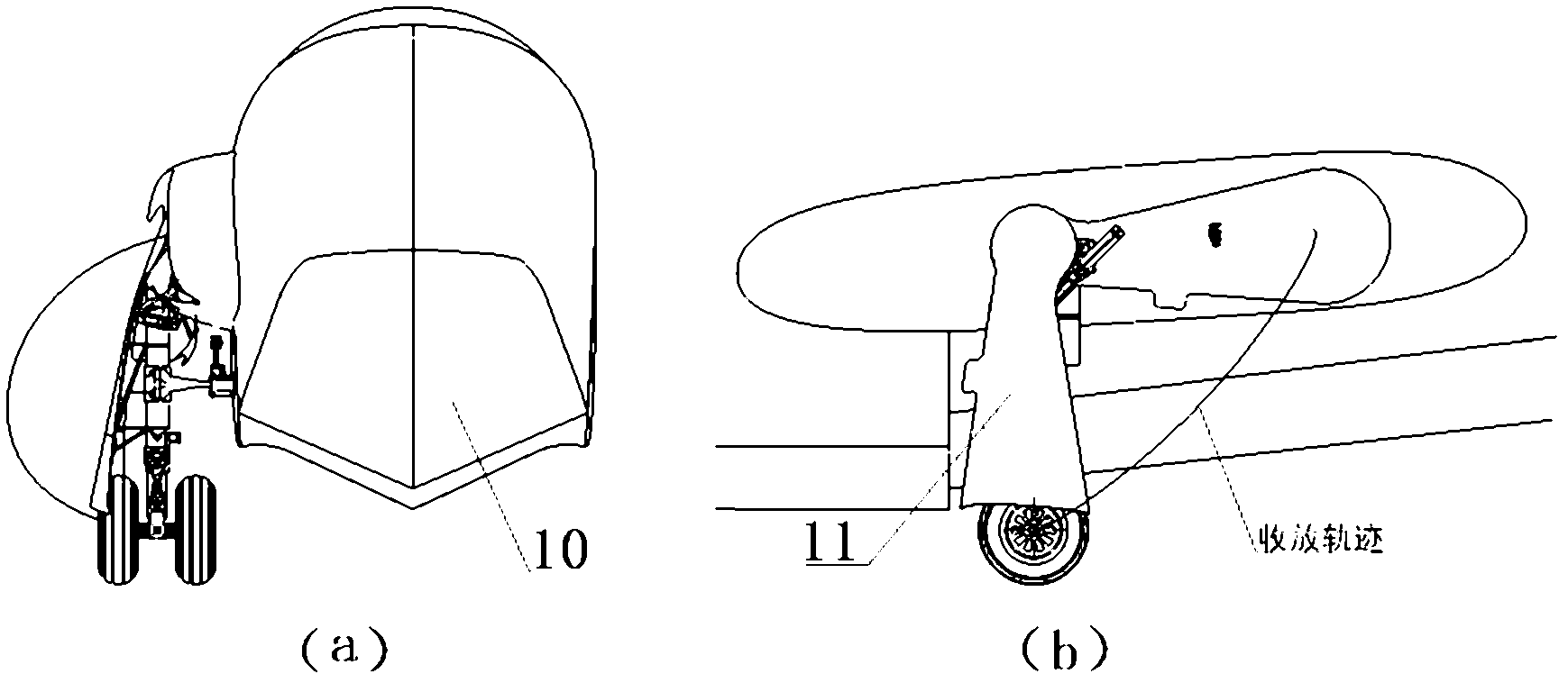

[0031] A space retractable mechanism for the main landing gear of an aircraft, such as image 3 and Figure 5 As shown, it includes a crossbeam 1 connected to the body 10, a bracket 8 hinged with the retractable actuator 9, and the other end of the crossbeam 1 is connected with the top of the outer cylinder 3 of the landing gear through the first universal hinge mechanism. The upper part of the outer cylinder 3 is connected with one end of a rocker arm 4 through the second universal hinge mechanism, and the other end of the rocker arm 4 is hinged with the bracket 8; the retractable actuator 9, the bracket 8 and a connecting rod assembly 6. The lever 7 constitutes a four-bar linkage drive mechanism; the axis OO of the hinge pivot 2 of the first universal hinge mechanism 1 , The connecting line OO between the hinge center points of the first universal hinge mechanism and the second universal hinge mechanism 3 , and the axis OO of the hinge pin of the rocker arm 4 and the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com