Automatic bag supplying machine

A bag supply and automatic technology, applied in the field of automatic packaging equipment, can solve the problems of manual separation and manual sorting of open pockets, which have a large impact on the production efficiency, and achieve the effects of reducing labor intensity, occupying less space, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

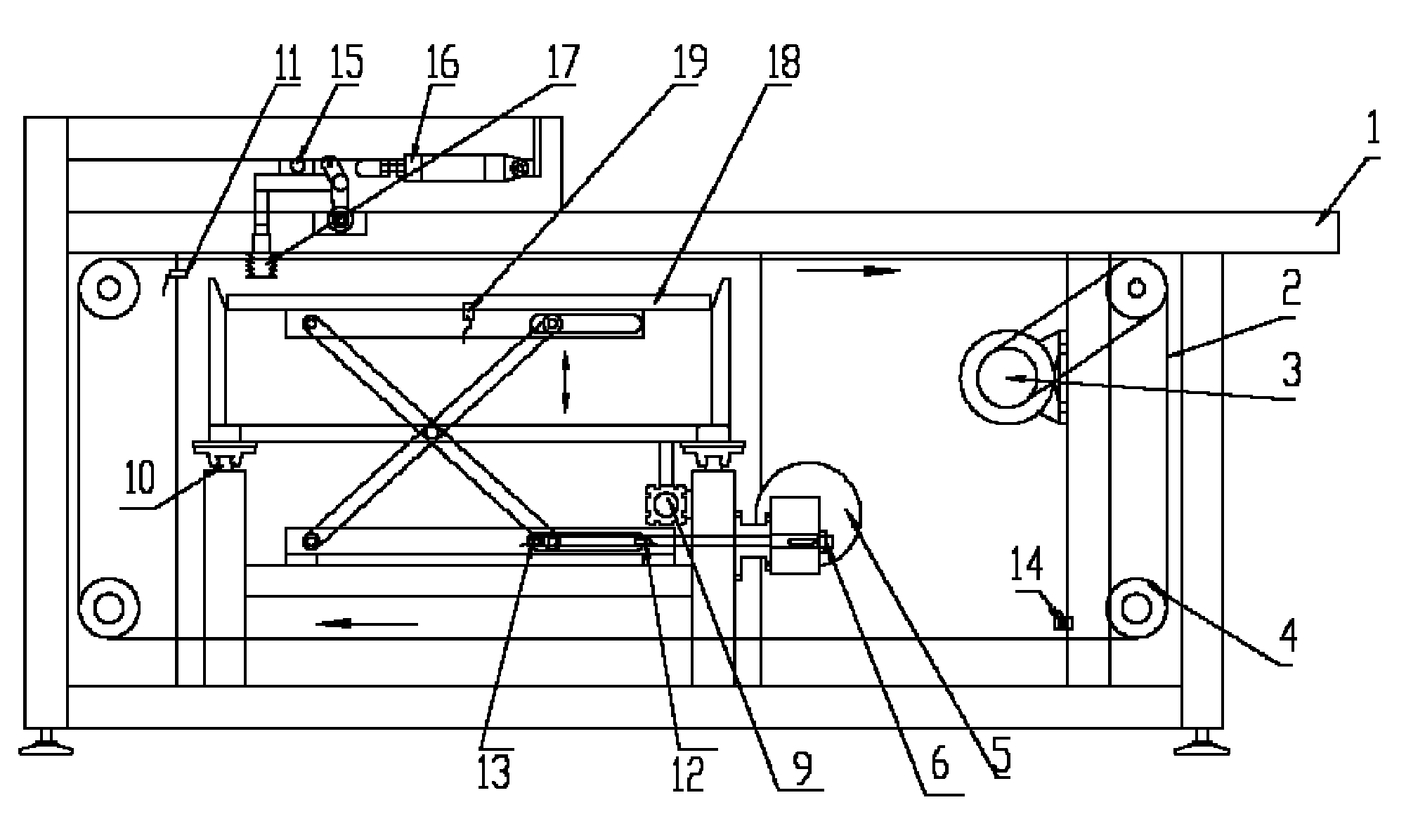

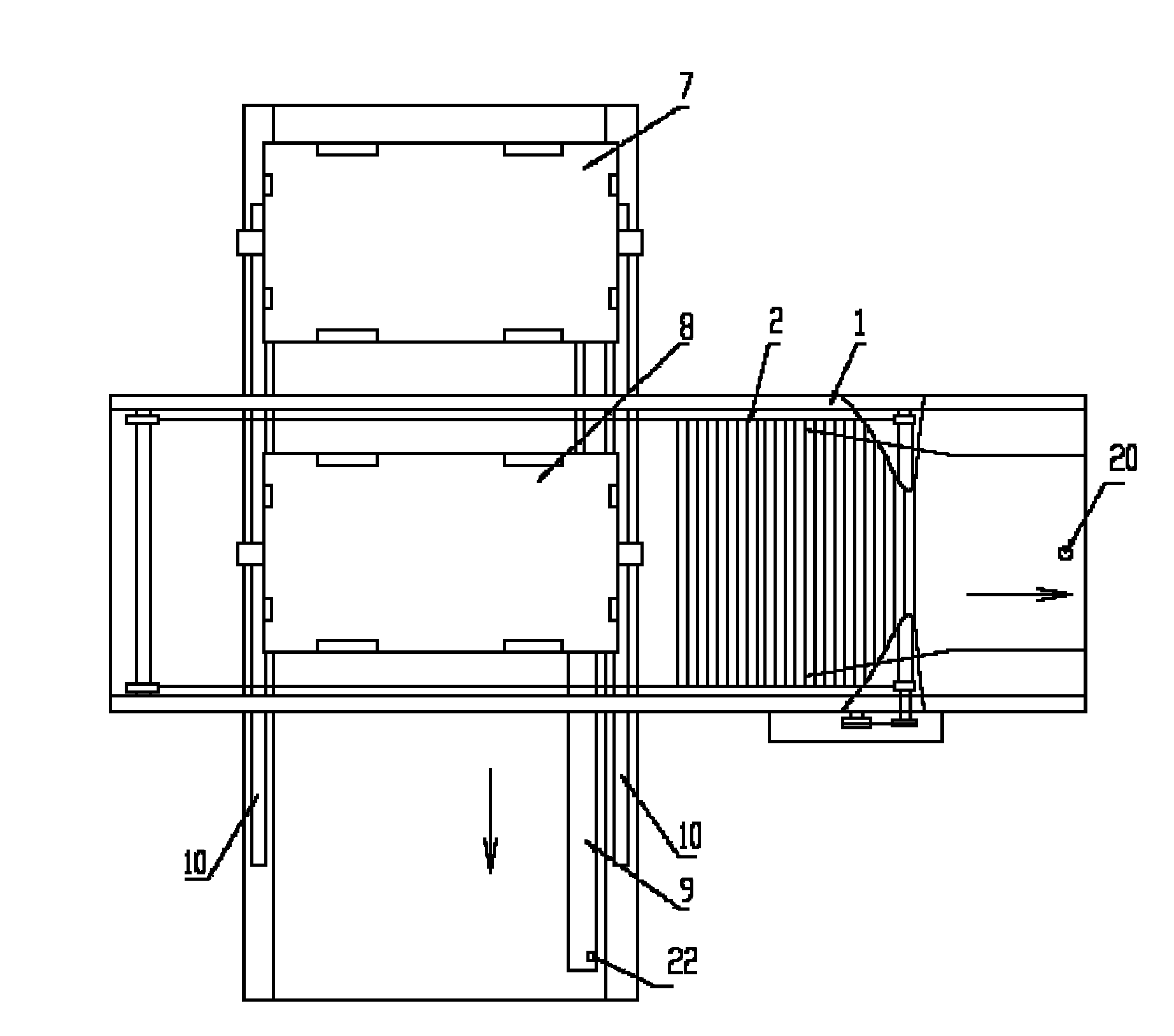

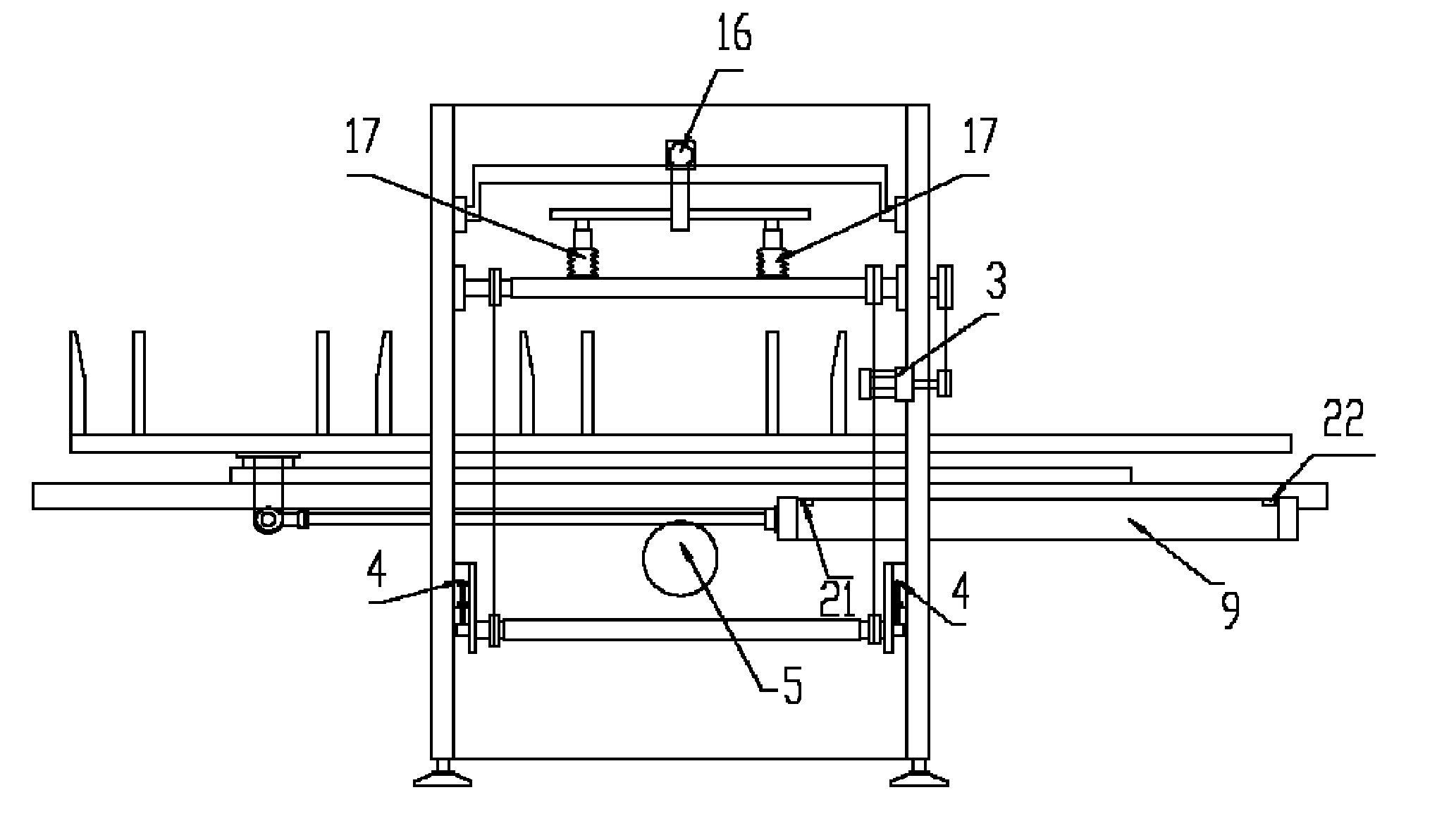

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0017] Put the bag into the bag storage (2) 8, move the storage cylinder 9 to drive the bag storage to move on the linear slide rail 10, drive the bag storage (2) 8 to the bag picking position, the bag detection sensor 19 detects the bag storage (2) Whether 8 has bags.

[0018] When the bag storehouse has bag detection sensor 19 and detects that there is a bag, when the bag storehouse rise control detection sensor 11 does not detect that there is a bag in the bag storehouse, the lift control motor 5 starts to drive the lift adjustment screw rod 6 to run, and the supporting movable bag tray 18 rises. Up to bag storehouse rising control detection sensor 11 detects tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com