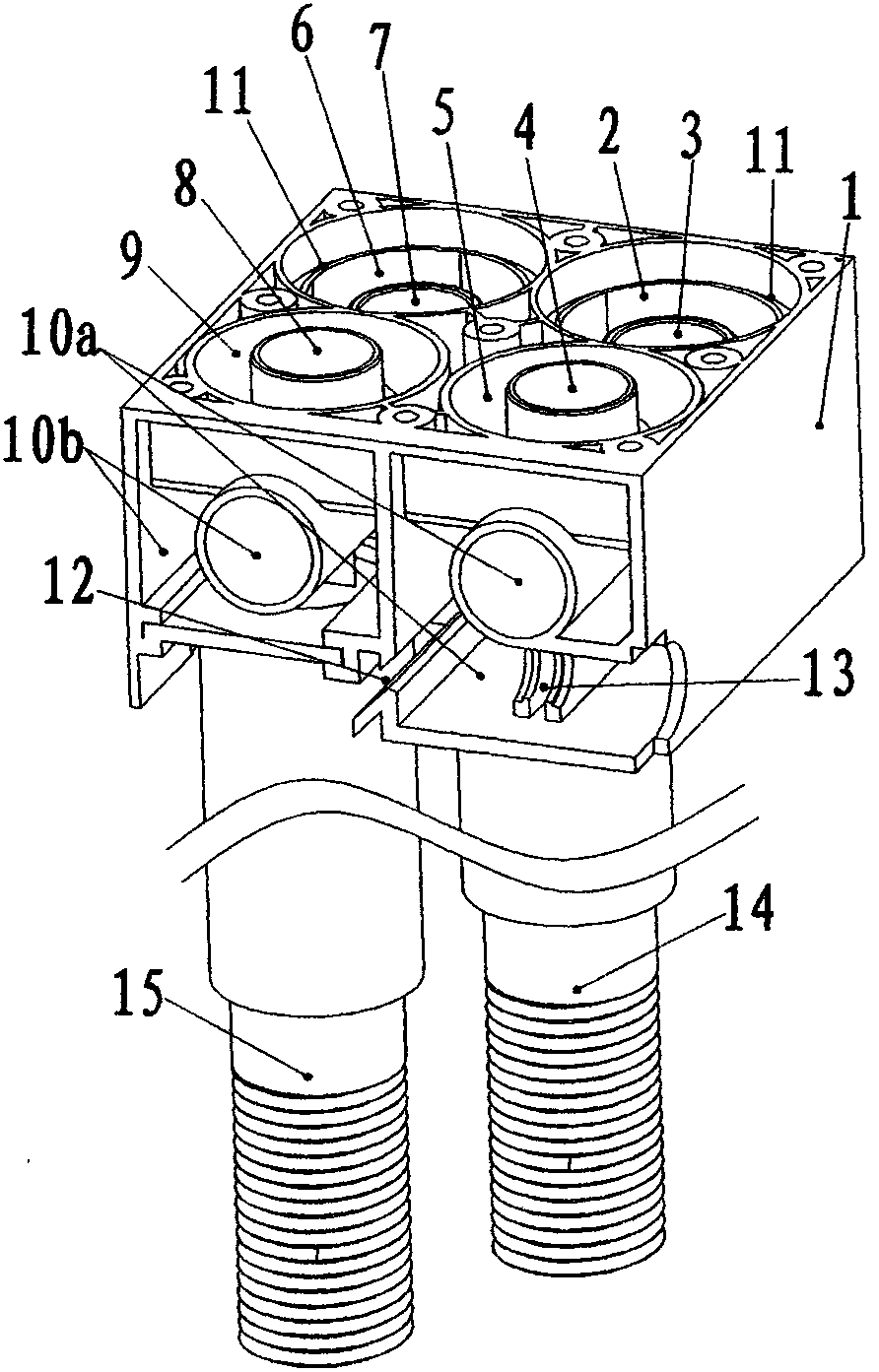

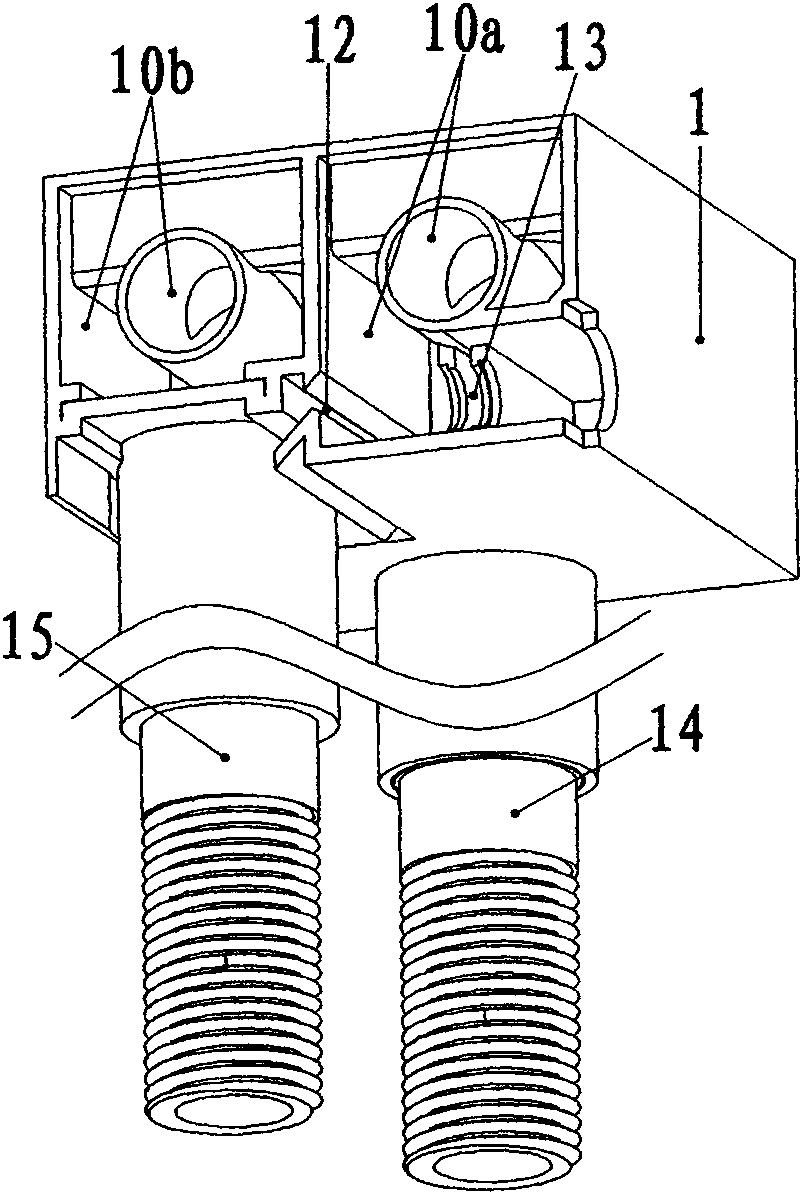

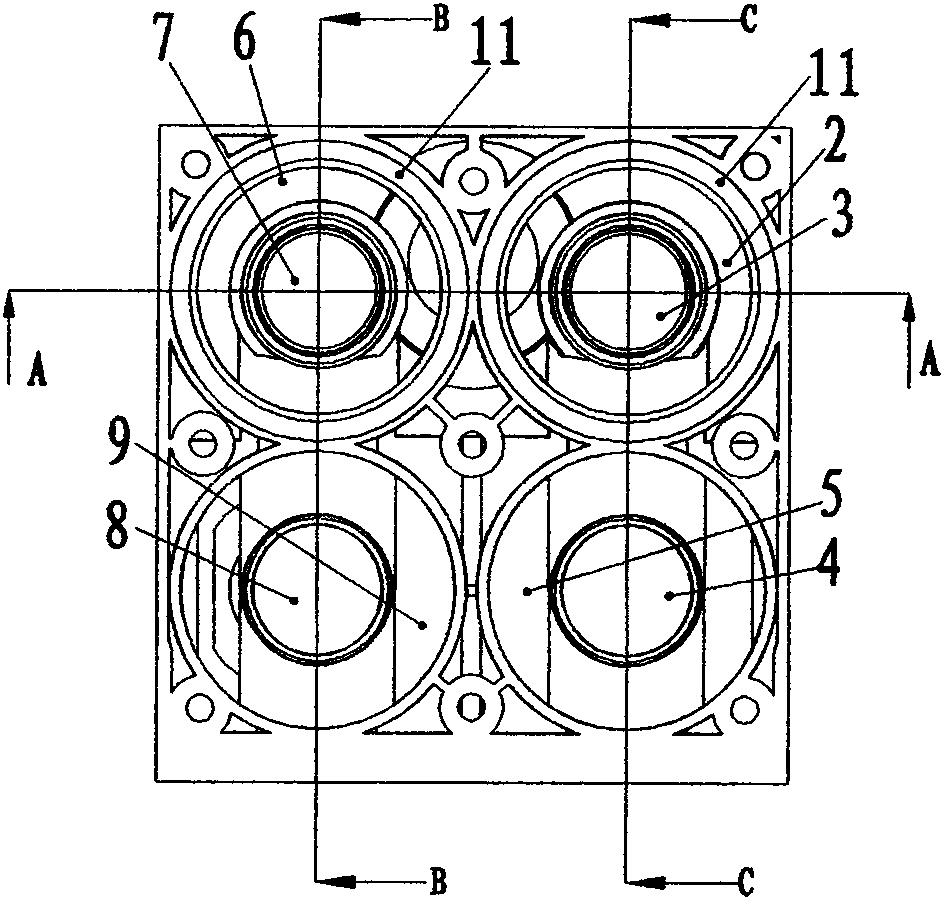

Injection water-saving device and toilet stool water-saving method

A water-saving device and toilet technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of high water pressure requirements, inability to clean the inner upper wall of the toilet, low water pressure, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0151] In specific embodiment one, the water outlet 12 is above the jet valve float tank B, the purpose of this design is to easily guide the water flowing out from the water outlet 12 to the jet valve float tank B so that the water in the jet valve float tank B When it is full, the jet valve float mechanism 30 floats up to close the jet valve. In fact, there are many ways to achieve this goal. The water outlet 12 does not have to be above the jet valve float tank B. In the second embodiment, the water outlet 12 Connect with the jet valve float tank B with a connecting pipe, so that all or part of the water flowing out from the water outlet 12 flows to the jet valve float tank B and then flows into the water tank, so that the purpose as in the first embodiment is achieved, and the rest All the components are exactly the same as those in the first embodiment, and the working principle and steps are also the same, which will not be repeated here.

specific Embodiment approach 3

[0152] In the first embodiment, a water inlet anti-siphon valve and a jet anti-siphon valve are set. In fact, the existence of the anti-siphon valve has no effect on the opening and closing of the water inlet valve and the jet valve. During water, running water pipeline can produce negative pressure, and anti-siphon valve core 43 moves down and covers water inlet anti-siphon valve inlet chamber 4 and jet anti-siphon valve inlet chamber 8, and air can be communicated up and down from main valve cover 16 again. Enter in the valve in the siphon ventilation groove 19, the negative pressure that running water pipe produces can not play a role to jet pipe 15, water outlet 12, replenishing water pipe 41 like this, guaranteed like this the water in the water tank and bedpan can not be sucked back; If Regardless of the above-mentioned factors, the anti-siphon valve may not be needed. On the basis of the first embodiment, as long as the anti-siphon valve core 43 is removed and the anti-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com