Clamping structure for fan column pipe

A column and fan technology, which is applied in the field of improvement and innovation technology, can solve the problems of time-consuming, labor-intensive and inoperable operation, and achieve the effect of simple structure realization and few parts and components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

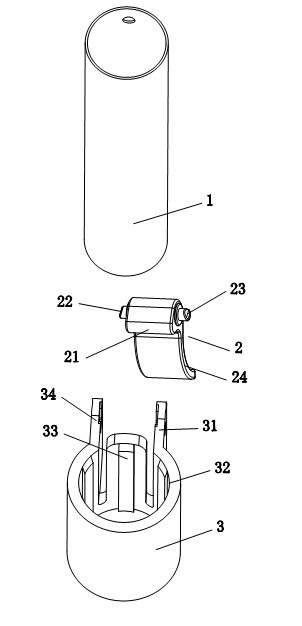

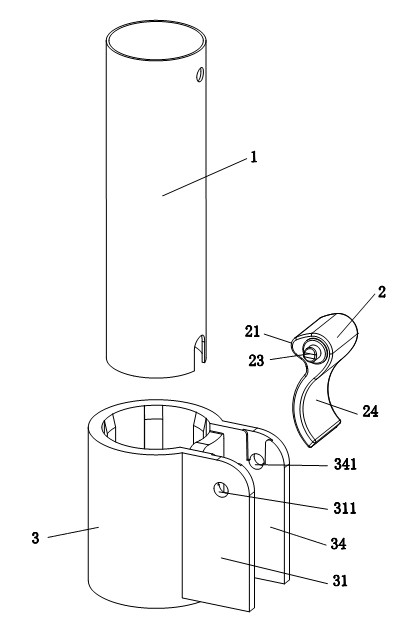

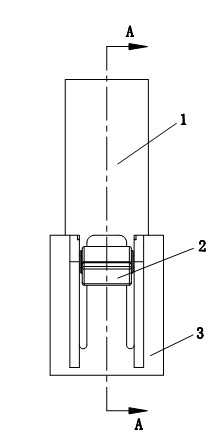

[0015] like Figures 1 to 6 As shown, a clamping and fixing mechanism for a fan column tube includes a column tube 1 and a body 3, one end of the column tube 1 can be directly inserted into the column tube hole 32 on the body 3, and the present invention is characterized in that it also includes a pressure rod 2; wherein the body 3 is provided with a first mounting arm 31 and a second mounting arm 34, and an elastic tongue structure 33 is provided on the wall of the body 3, and the elastic tongue structure 33 is located on the first mounting arm 31 and the second mounting arm 34; Between the mounting arms 34; the pressure rod 2 is installed between the first mounting arm 31 and the second mounting arm 34, the pressure rod 2 is a lever structure, and the long end of the pressure rod 2 is an exposed and operable movable buckle 24. The short end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com