Backlight module

A technology of backlight module and light source, which is applied in the direction of optics, light guide, light source, etc., can solve the problems of backlight module thickness, uneven light output, and difficult alignment of light source and light guide plate, etc., to increase incident area, reduce weight, and better counterpoint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

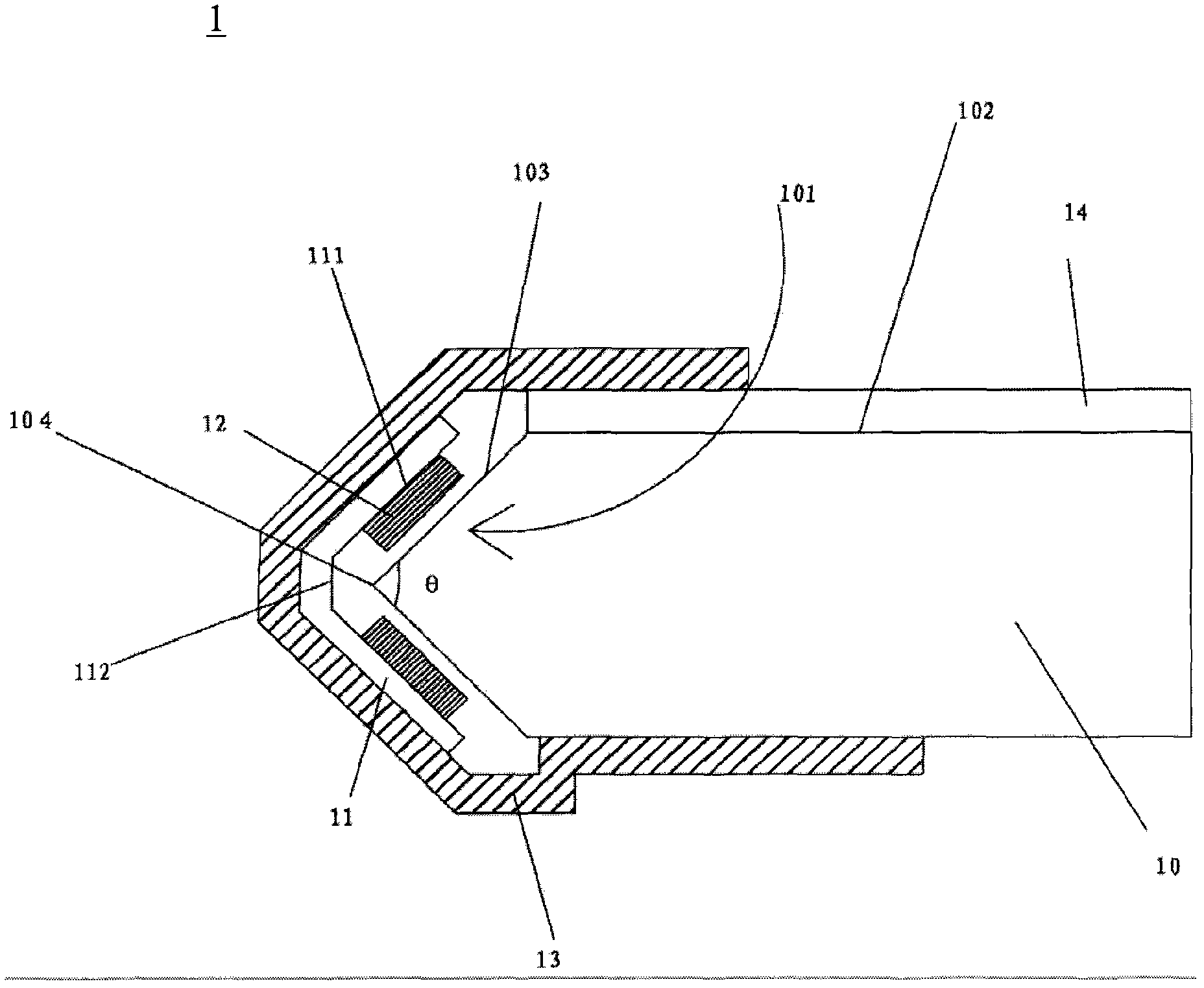

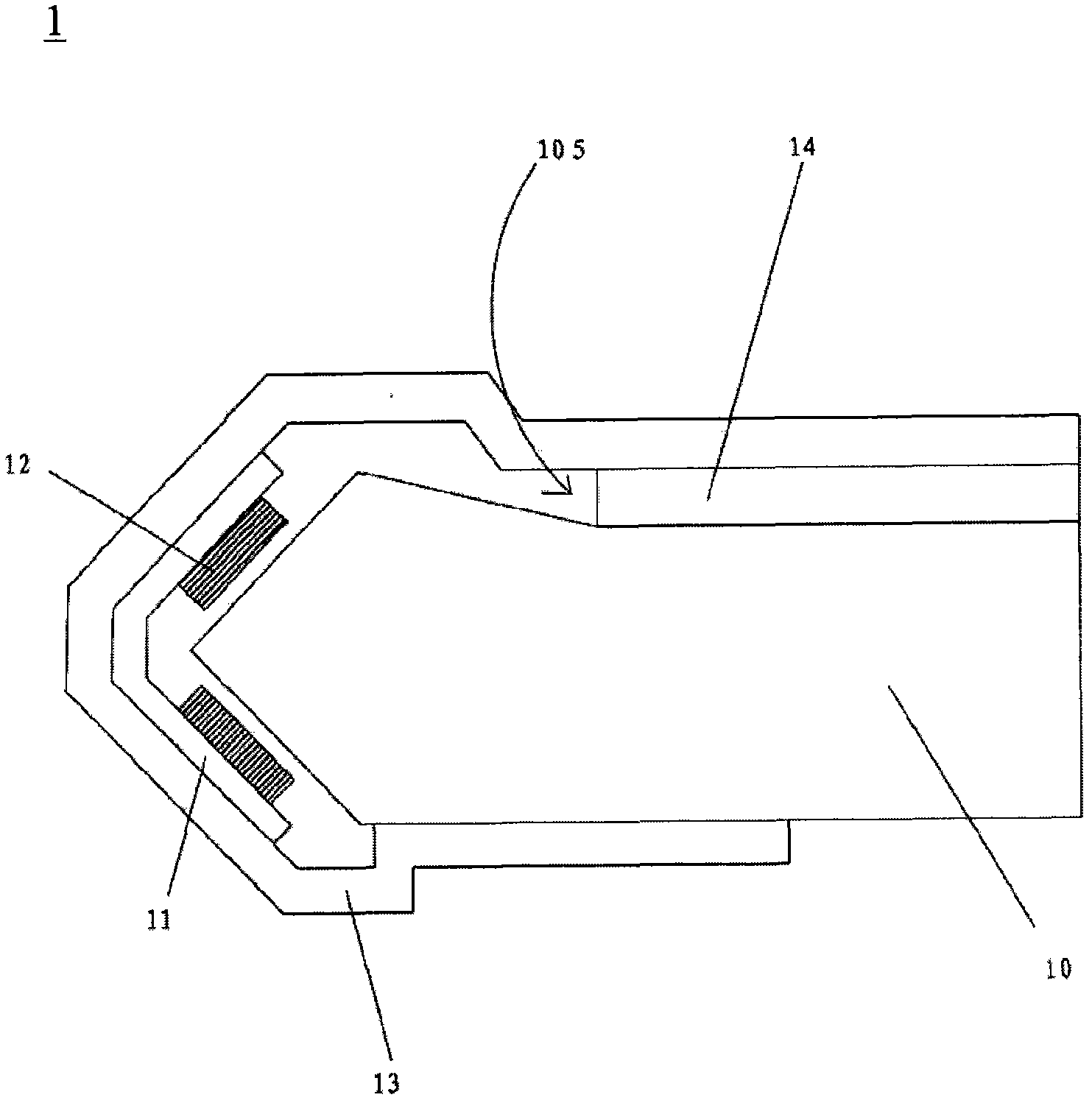

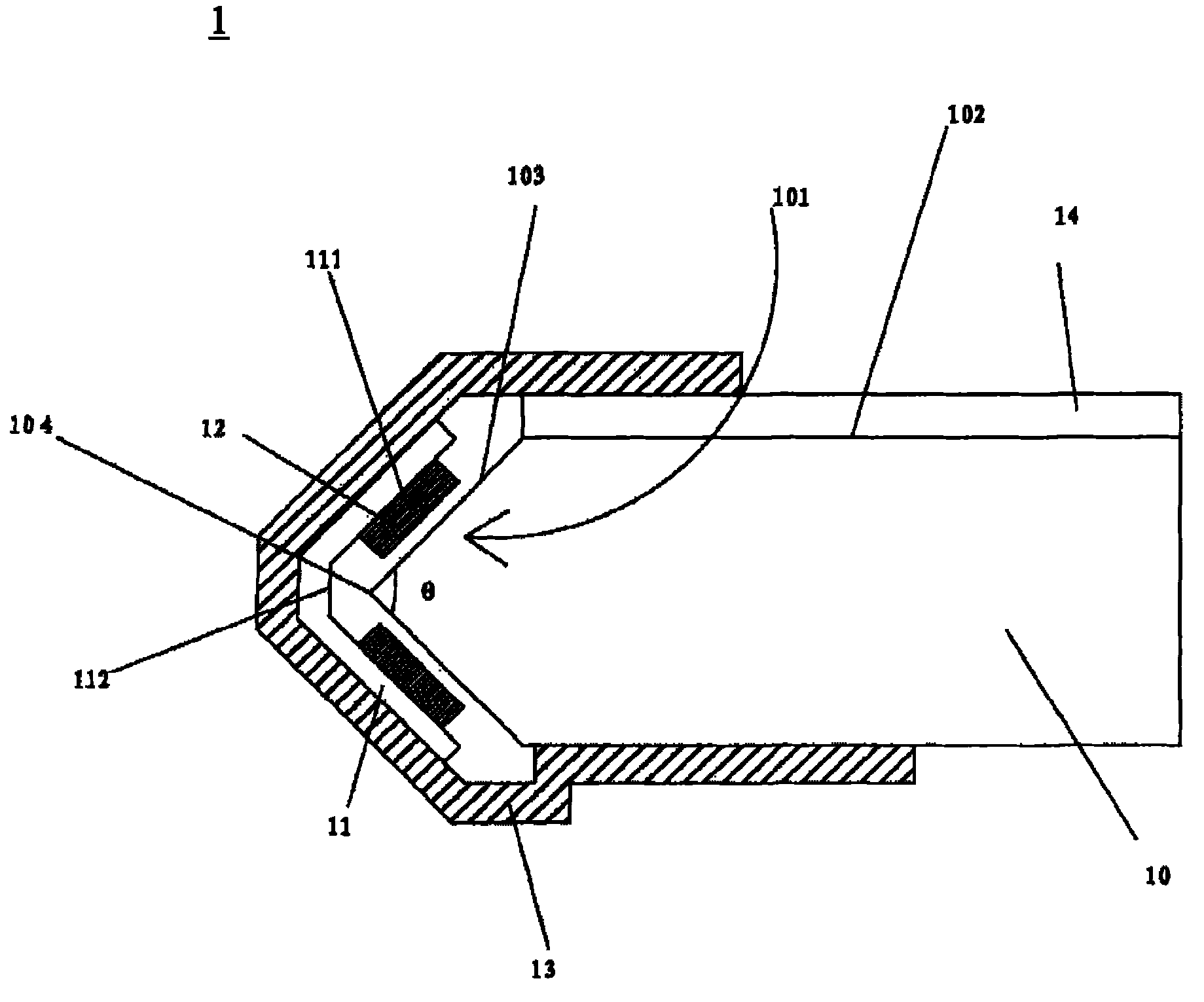

[0019] figure 1 A schematic structural diagram of a backlight module according to an embodiment of the present invention is shown. refer to figure 1 , The backlight module 1 includes: a light guide plate 10 , a circuit board 11 , a plurality of light sources 12 , an outer frame 13 and an optical film 14 . Wherein, the light guide plate 10 has a light incident surface 101 and a light exit surface 102, the light incident surface 101 is located on one side of the light guide plate 10, and is formed symmetrically by two first slopes 103, and the two first slopes 103 are connected to each other to form an included angle θ , in this embodiment, the included angle θ is a right angle, and in other embodiments, the included angle θ may be an acute angle. The light emitting surface 102 is a flat surface. The circuit board 11 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com