Lamp shell with air flow diversion cooling effect

A heat dissipation and air diversion technology, applied in the field of lighting, can solve the problems that the heat conduction base panel cannot achieve auxiliary heat dissipation effect, burn the lamp body and circuit board, and gather in the middle of the lamp pool, etc., so as to facilitate the transfer of heat, The effect of extending the service life and ensuring the effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail and completely below in conjunction with the accompanying drawings.

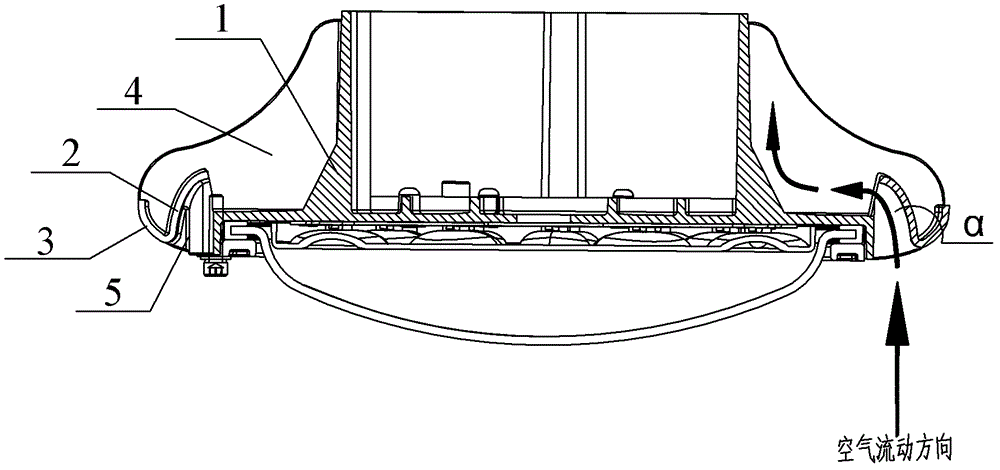

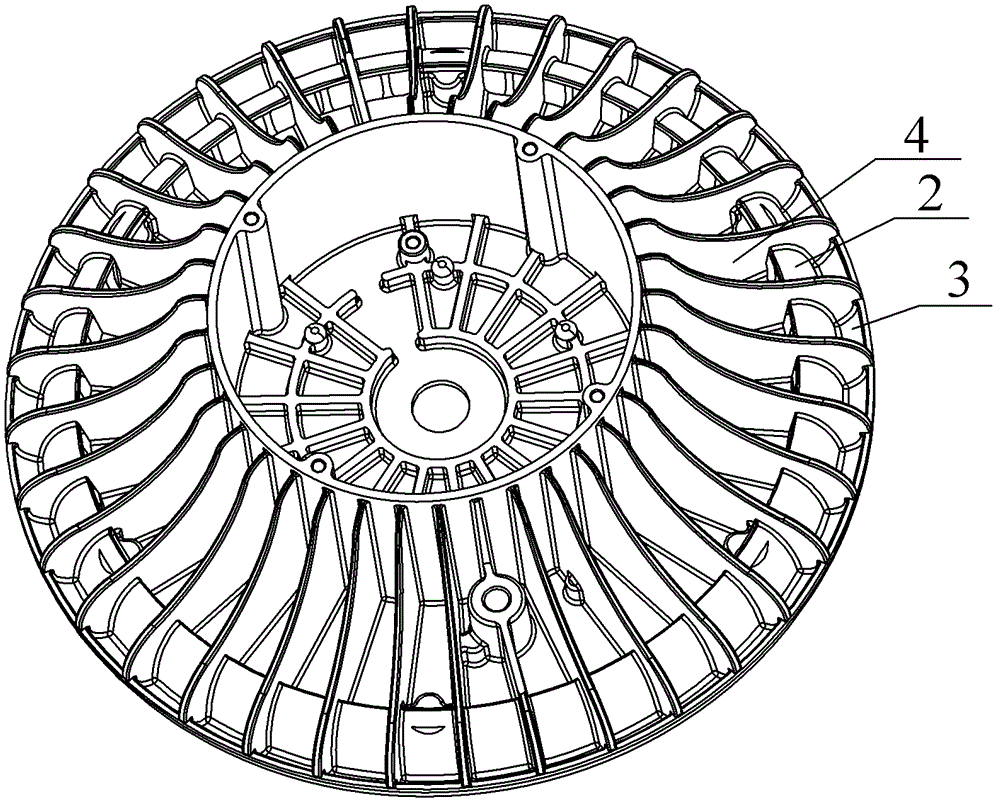

[0017] Such as figure 1 with figure 2 As shown: a lamp housing with air conduction and heat dissipation provided by the present invention is characterized in that: a guide member is provided on the circumference of the lamp housing 1, and the guide member is formed by an inward concave The arc-shaped deflector 2 is formed with the outwardly concave arc-shaped edge plate 3, and the formed section is obliquely hook-shaped; the angle α of the formed obliquely hook is preferably an acute angle; between the outer casing and the flow-guiding member Also be provided with some heat dissipation fins 4, and described heat dissipation fins 4 are evenly distributed in the circumference of housing; The groove that is formed by deflector plate is provided with some partition plates 5 on the inner side of housing, and described partition plate 5 and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com