Air filter for heavy duty vehicles with air flow characteristics

An air filter and air flow technology, which is used in combustion air/combustion-air treatment, engine components, machines/engines, etc., can solve the problem that the overall performance of the engine cannot be effectively improved, the structural design is unreasonable, and the service life is affected. and other problems, to achieve the effect of easy popularization and application, simple structure and reduction of air intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

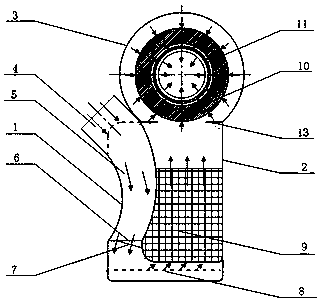

[0023] Accompanying drawing is the specific embodiment of the present invention.

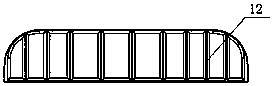

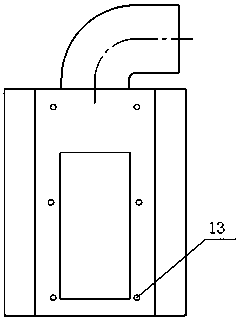

[0024] Such as figure 1 , figure 2 and image 3 The shown air filter for heavy-duty vehicles according to the air flow characteristics of the present invention includes an inlet part 1, a coarse filter 2 and a fine filter 3, and the inlet part 1 includes a circular intake pipe 4 and an arc-shaped intake pipe 5 and the air intake grid 6, the air intake grid 6 is integrally connected with the housing of the coarse filter 2, and a rib plate 7 is installed on the lower side, and eight support columns 12 are arranged on the air intake grid 6; The coarse filter 2 comprises an oil pool 8 and a steel wire strainer 9, and the lower partition of the coarse filter 2 is an arc, and the radius of the arc is 55-60mm; stage filter element 11, and the fine filter 3 is arranged on the upper end of the outlet of the coarse filter 2.

[0025] The ribs 7 are arranged in three places, respectively corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com