A New Design Method for Airfoil of Bidirectional Axial Flow Pump

A technology of airfoil design and design method, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as cavitation, poor cavitation resistance, vibration, etc., and achieve low efficiency , easy operation, and simple design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0030] A novel method for designing the airfoil of a bidirectional axial flow pump, including a common axial flow pump blade designed with NACA airfoil, the steps are as follows:

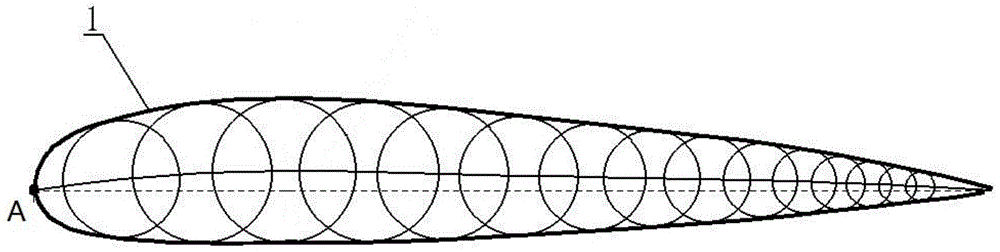

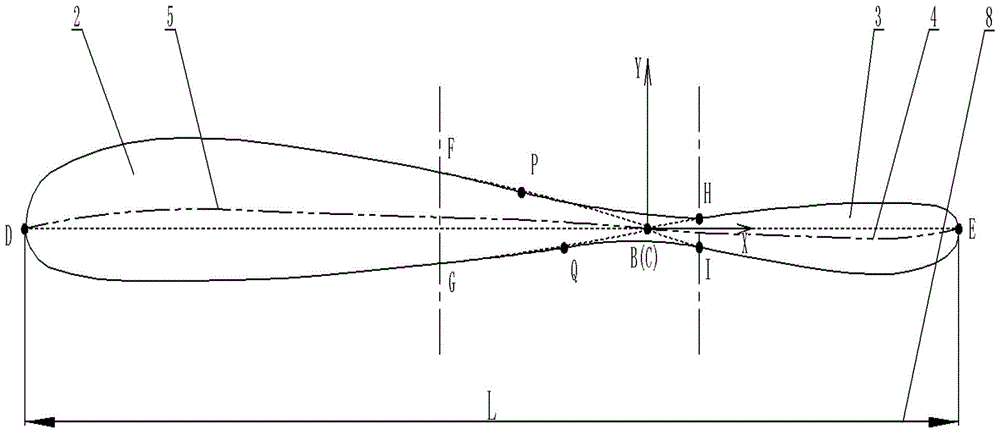

[0031] (1) Measure the airfoil coordinates of the common axial flow pump blade by a three-coordinate measuring instrument, thereby draw the corresponding airfoil on the xy coordinate axis, and obtain the original airfoil 1; as figure 1 As shown, the chord length of the original airfoil 1 is 100 mm, the relative camber is 2%, the relative thickness is 12%, and the maximum camber position is located at 2 / 5 of the chord length.

[0032] (2) On the xy coordinate axis, the bone line leading edge point A of the original airfoil 1 is placed at the origin (0,0), and the original airfoil is enlarged by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com